Asphalt thermal-insulation and waterproof coiled material and preparation method thereof

A technology for waterproofing membrane and bitumen, which is applied in bitumen layered products, chemical instruments and methods, roofing using flexible materials, etc., can solve the problems of poor sunlight reflection performance, direct sunlight, and poor thermal insulation effect. , to achieve good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

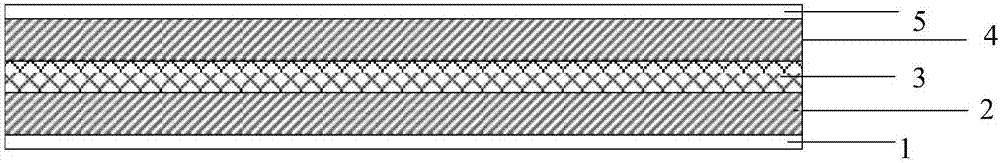

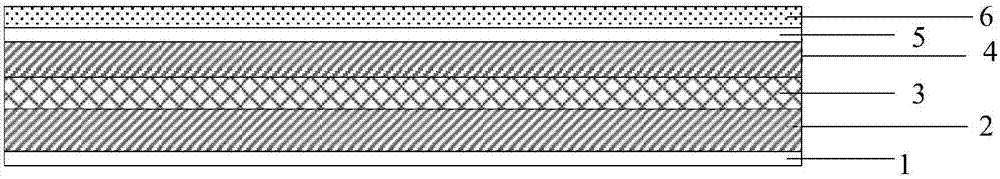

[0038] The embodiment of the present invention provides an asphalt heat insulation and waterproof coiled material, such as figure 2 As shown, the asphalt heat-insulating and waterproofing membrane comprises from bottom to top: a first isolation membrane 1, a first asphalt layer 2, a base layer 3, a second asphalt layer 4, a first isolation membrane 5 and a reflective heat insulation layer 6 .

[0039] It can be seen that the asphalt heat insulation and waterproof membrane of the embodiment of the present invention adds a reflective heat insulation layer 6 on the surface of the existing asphalt waterproof membrane, and the new asphalt heat insulation and waterproof membrane not only has waterproof function, but also has the function of reflecting sunlight The function can achieve good heat insulation effect. Moreover, when the exterior wall or roof of the building has waterproof function and reflective heat insulation function at the same time, the required construction proce...

Embodiment 2

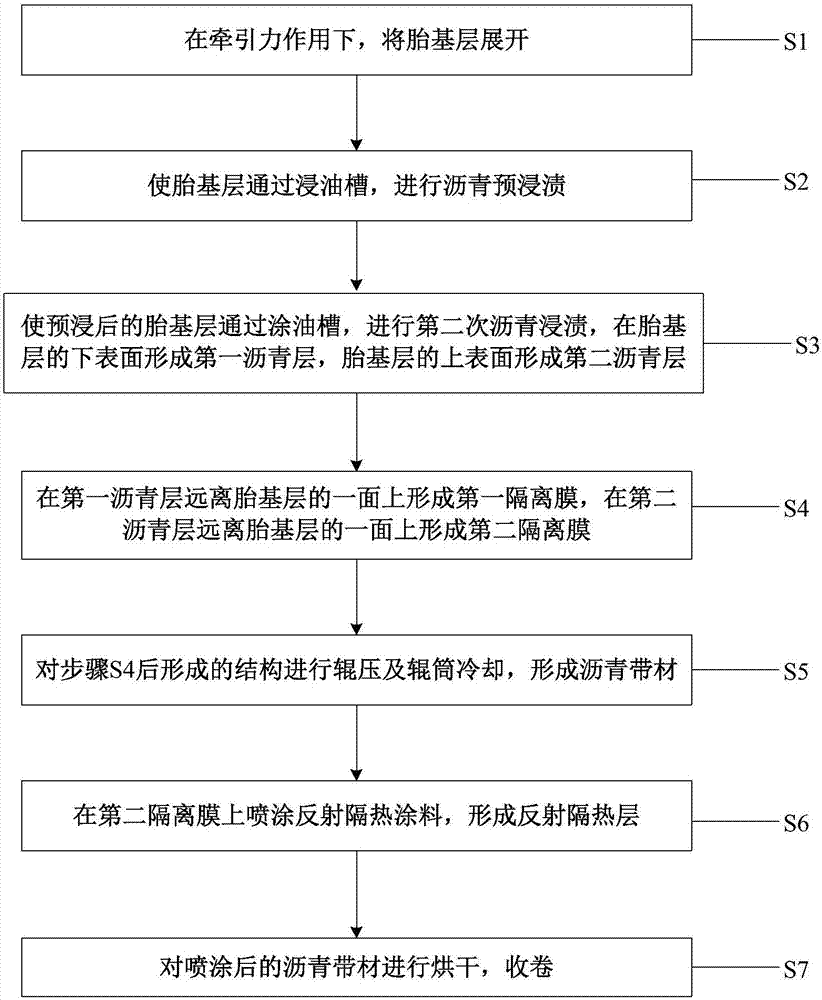

[0044] Embodiment 2 of the present invention provides a process for preparing an asphalt heat-insulating and waterproof membrane. The asphalt heat-insulating and waterproof membrane is subjected to traction during the entire preparation process, such as image 3 As shown, the preparation process of asphalt thermal insulation and waterproof membrane specifically includes the following steps:

[0045] Step S1, unfolding the base layer of the tire;

[0046] Step S2, making the base layer pass through the oil immersion tank at a constant speed to perform asphalt pre-impregnation;

[0047] Step S3, passing the pre-impregnated base layer through the oiling tank at a constant speed, performing a second asphalt impregnation, forming a first asphalt layer on the lower surface of the base base, and forming a second asphalt layer on the upper surface of the base base;

[0048] Step S4, forming a first isolation film on the side of the first asphalt layer away from the base layer, and fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com