Petroleum drilling additive with polypropylene ammonium salt and preparation method of petroleum drilling additive

A polypropylene ammonium salt, oil drilling technology, applied in the directions of chemical instruments and methods, drilling compositions, etc., to achieve the effects of reducing filtration loss, reducing usage, and improving cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1 Take by weighing acrylic fiber 100kg, water 600kg, catalyst potassium polyuretate 7kg polyacrylamide 0.7kg sodium carboxymethyl cellulose 21kg, drop in the reactor, the reactor is airtightly heated, when the reactor temperature reaches 200%, Stop heating, at this time the corresponding pressure should be 1.5Mpa, keep the temperature for 12 hours, and when all the raw materials in the reactor are hydrolyzed from the liquid body to the liquid body, reduce the temperature to 170, put the semi-finished product formed at ℃ into the liquid storage tank, and the liquid will After spray drying at about 160°C, the hydrolyzed polyacrylonitrile compound ammonium salt is formed.

Embodiment 2

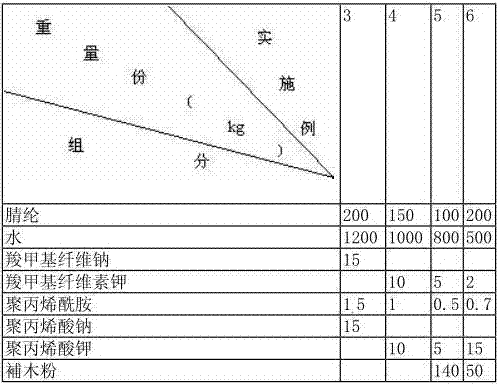

[0013] Example 2 After spray drying in Example 1 to generate hydrolyzed polyacrylonitrile compound ammonium salt, add 25kg of Phoebe powder that has passed through a 20 mesh sieve. The specific preparation method of Example 3-6 is the same as that of Example 1 or Example 2, except for the components The weight proportions are different, but all have the effect indicated by the present invention.

[0014]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com