Bamboo (wood) frame structure beam column assembly type energy consumption joint

A frame structure and prefabricated technology, applied in building components, building structures, protected buildings/shelters, etc., can solve problems such as inconvenient construction, difficult construction, weak bearing capacity, etc. The effect of convenience and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the drawings.

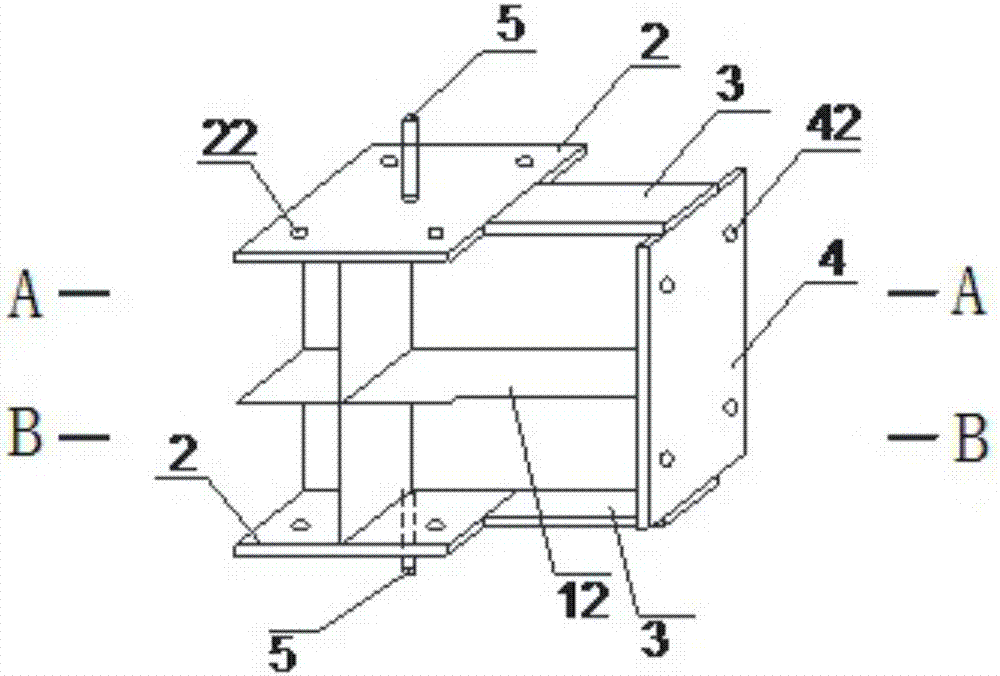

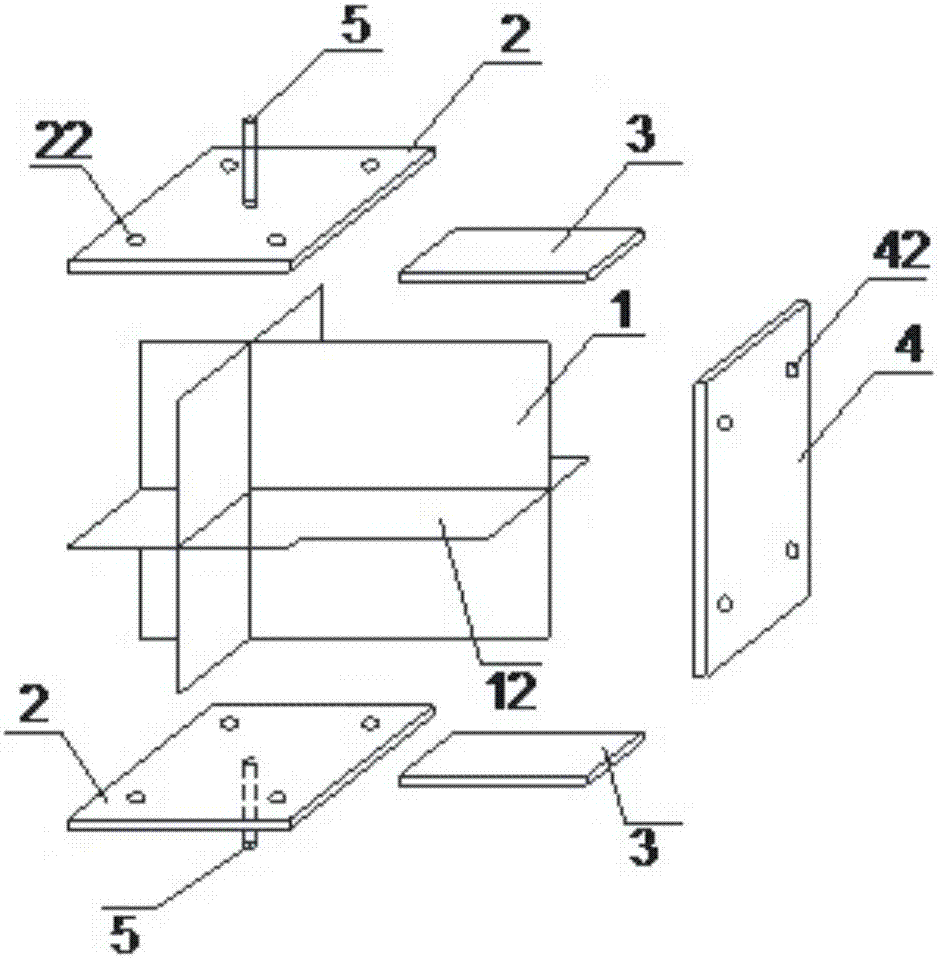

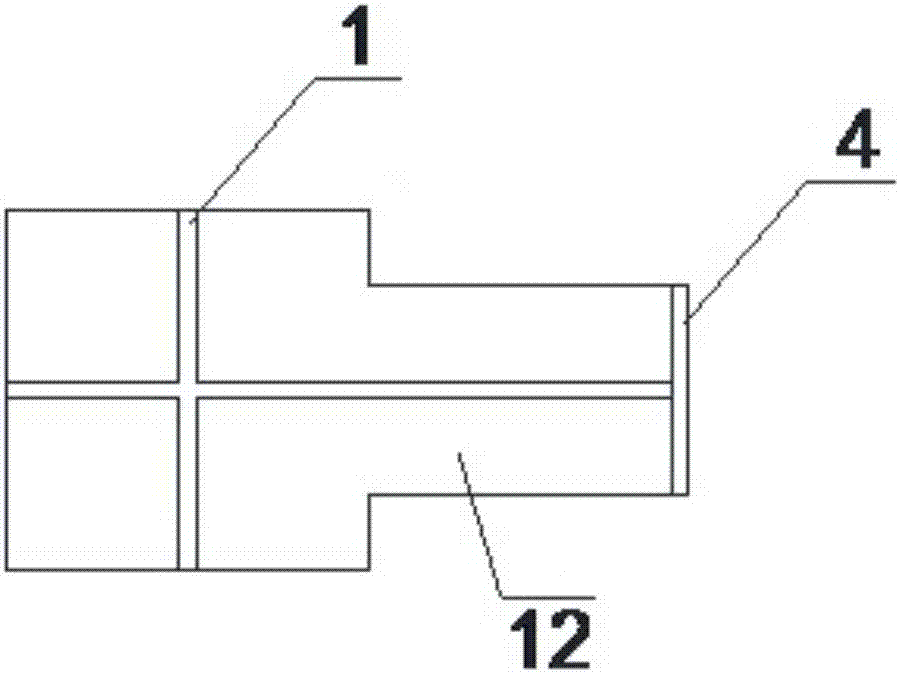

[0025] The overall structure of the bamboo (wood) frame structure beam-column assembled energy-consuming node of the present invention is as figure 1 with figure 2 Shown, where, figure 1 The sectional structure diagram in the A-A direction is as follows image 3 As shown, figure 1 The sectional structure diagram in the direction of B-B is as follows Figure 4 Shown.

[0026] The bamboo (wood) frame structure beam-column assembled energy-consuming node of the present invention includes a cross-shaped steel column 1, a horizontal strengthening steel plate 12, a column connection steel plate 2, a beam flange steel plate 3, a beam connection steel plate 4, a positioning steel rod 5, and a reinforcement bolt 6 , Bamboo (wood) pillar 7, bamboo (wood) beam 8. Three steel plates are welded to form a cross-shaped steel column 1, and a horizontal reinforcing steel plate 12 is welded in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com