Auxiliary heating drilling type freezing core-taking drilling tool

A technology for auxiliary heating and coring drilling tools, which is applied in the direction of extracting undisturbed core devices, earthwork drilling and mining, etc., can solve problems such as uncontrollability, and achieve the effects of accelerated efficiency, simple structure, and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

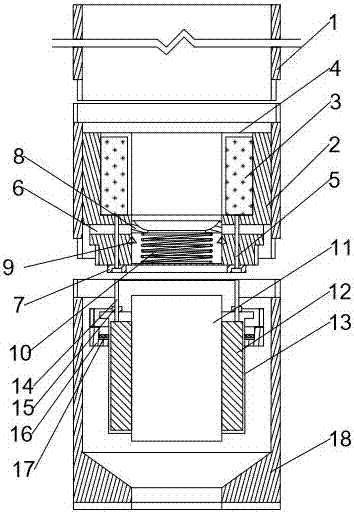

[0017] see figure 1 As shown, the present invention is composed of a power supply module, an auxiliary heating drilling frozen coring module, and a conventional drilling tool module. The power supply module is located at the upper end of the auxiliary heating drilling frozen coring module. The space is connected and fixed by the snap button 16, and the power supply is provided by plugging. The power supply module and the auxiliary heating drilling, freezing and coring module are installed in the conventional drilling tool module;

[0018] The power supply module is composed of a battery fixing card holder 2, a battery 3, a battery protective case 4, a pin seat 5, a concave pin sealing seat 7, a ball drop base 8, a single-action contact switch 9, and a spring 10. The battery fixing card The base 2 is fixed on the conventional drilling tool 1, the battery 3 is installed on the battery fixing holder 2, the battery protection case 4 is arranged outside the battery 3, and the mud c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com