Preparation and production process of pineapple freeze-dried Chinese wolfberry snacks

A production process and technology of dried wolfberry, which is applied in the fields of food preservation, food science, fruit and vegetable preservation, etc., can solve the problems of natural lack of product nutrition, insufficient understanding of wolfberry, poor palatability, etc., and achieve safe and reliable consumption, sublimation and freeze-drying. The effect of short time and extended shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

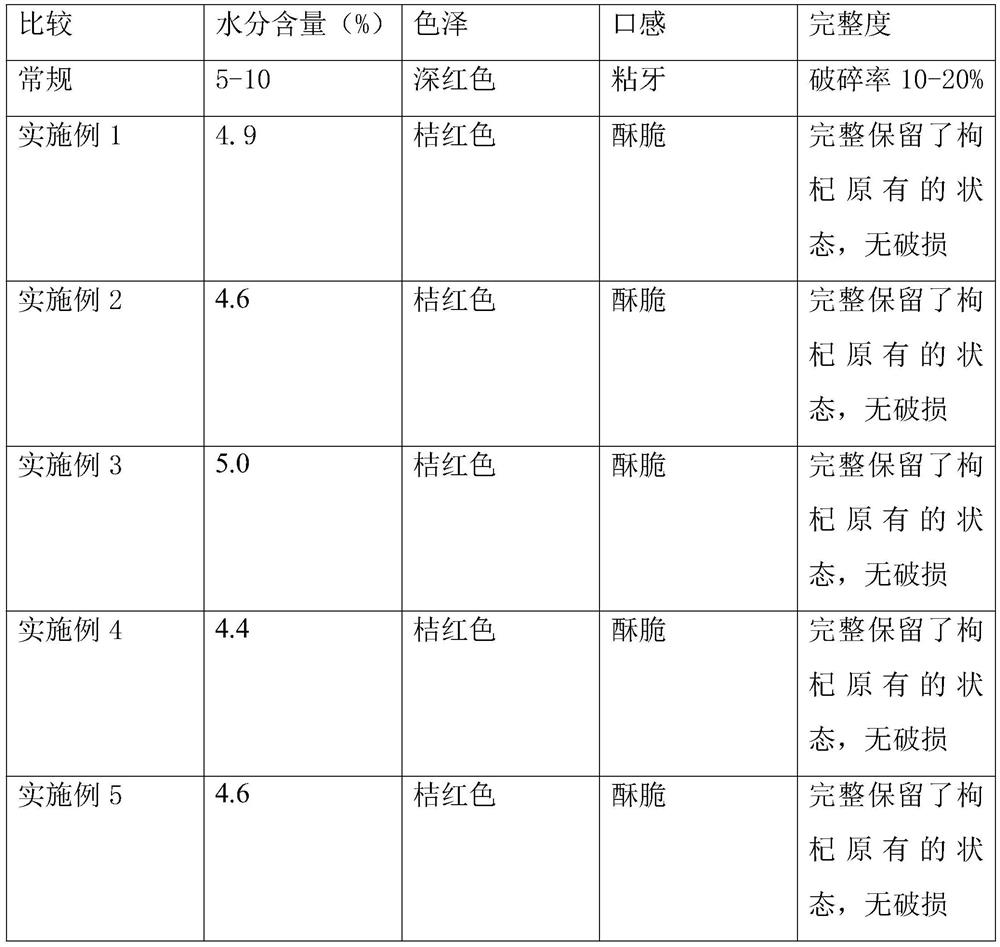

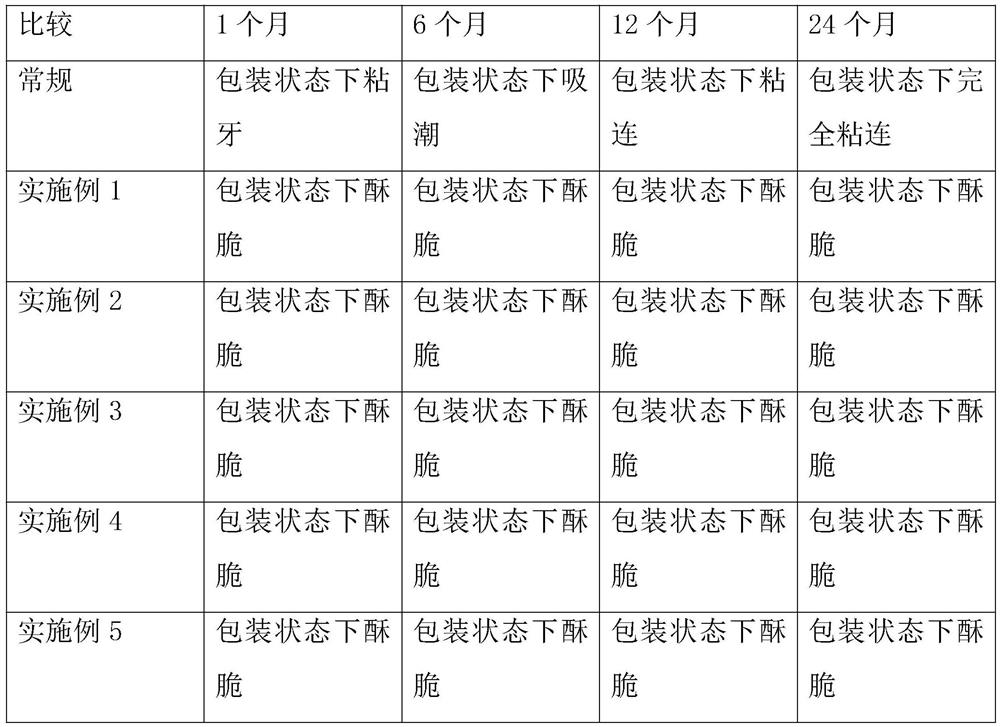

Examples

Embodiment 1

[0027] (1) Select organic fresh fruit of wolfberry as raw material, specifically, select fresh fruit of wolfberry with bright color, full grain and complete fruit, and remove impurities such as leaves, branches, gravel and inferior fruit. Then, after washing and draining the fresh wolfberry fruit, in a well-ventilated clean workshop, keep the room well-ventilated, control the temperature at 20°C, put it on a plate and dry it naturally in the shade to obtain dried wolfberry with a water content of 30%;

[0028] (2) Remove slag after beating the fresh pineapple, beat at low temperature, keep the temperature of the colloid mill cavity at 5°C, and control the slag-liquid ratio of 1:9 to obtain pineapple juice and pineapple residue;

[0029] (3) First put the dried wolfberry obtained in step (1) into the low-temperature pineapple juice and soak for 6 hours, then pack the wolfberry material into a plate to obtain the wolfberry material, transfer it to the quick-freezing warehouse, an...

Embodiment 2

[0031] (1) Select organic fresh fruit of wolfberry as raw material, specifically, select fresh fruit of wolfberry with bright color, full grain and complete fruit, and remove impurities such as leaves, branches, gravel and inferior fruit. Then, after washing and draining the fresh wolfberry fruit, in a well-ventilated clean workshop, keep the room well ventilated, control the temperature at 25° C., put it on a plate and dry it naturally in the shade to obtain dry wolfberry with a water content of 25%.

[0032] (2) Remove slag after beating the fresh pineapple, beat at low temperature, keep the temperature of the colloid mill cavity at 8°C, and control the slag-liquid ratio of 1:8 to obtain pineapple juice and pineapple residue;

[0033] (3) First put the dried wolfberry obtained in step (1) into the low-temperature pineapple juice and soak for 7 hours, then pack the wolfberry material into a plate to obtain the wolfberry material, transfer it to the quick-freezing warehouse, an...

Embodiment 3

[0035] (1) Select organic fresh fruit of wolfberry as raw material, specifically, select fresh fruit of wolfberry with bright color, full grain and complete fruit, and remove impurities such as leaves, branches, gravel and inferior fruit. Then, after washing and draining the fresh wolfberry fruit, in a well-ventilated clean workshop, keep the room well ventilated, control the temperature at 18° C., put it on a plate and dry it naturally in the shade to obtain dry wolfberry with a water content of 26%.

[0036] (2) Remove slag after beating the fresh pineapple, beat at low temperature, keep the temperature of the colloid mill cavity at 9°C, and control the slag-liquid ratio of 1:10 to obtain pineapple juice and pineapple residue;

[0037] (3) First put the dried wolfberry obtained in step (1) into the low-temperature pineapple juice and soak for 5 hours, then pack the wolfberry material into a plate to obtain the wolfberry material, transfer it to the quick-freezing warehouse, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com