A kind of processing method and application of slightly freeze-dried wolfberry

A processing method and technology of wolfberry, applied in application, fruit and vegetable preservation, food science, etc., can solve the problems of sugar liquid leakage, product brittleness, fragility, etc., and achieve the effects of easy storage, short sublimation, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of processing method of slightly freeze-dried Chinese wolfberry, carries out according to following steps:

[0023] (1) Soaking and cleaning: Pick fresh wolfberry fruits with or without fruit stalks and soak them in ozone water with a concentration of 1 mg / L for 5 minutes to remove and reduce microorganisms, impurities and pesticide residues on the surface of wolfberries;

[0024] (2) Freeze-drying protection: Drain the cleaned wolfberry to remove the surface moisture and put it into the tray in a single layer, and then put the prepared freeze-drying protection agent containing trehalose (w / w) 2% and calcium chloride 0.5% into the mist Spray the chemical nozzle evenly on the surface of wolfberry, put it into the freeze dryer and start vacuuming without heating and freezing, and keep the negative pressure for 10 minutes after the pressure drops to 60 Pa;

[0025] (3) Freeze-drying: Slowly pressurize the freeze-drying chamber to normal pressure and then turn on the...

Embodiment 2

[0027] (1) Soaking and cleaning: Pick fresh wolfberry fruits with or without fruit stalks and soak them in ozone water with a concentration of 5 mg / L for 10 minutes to remove and reduce microorganisms, impurities and pesticide residues on the surface of wolfberry;

[0028] (2) Freeze-drying protection: Drain the cleaned wolfberry to remove the surface moisture and put it into the plate in a single layer, and then put the prepared trehalose (w / w) 1% to 10%, calcium chloride (w / w) 81 % of the freeze-drying protective agent is evenly sprayed on the surface of wolfberry with an atomizing nozzle, put into the freeze dryer and start vacuuming without heating and freezing, and keep the negative pressure for 30 minutes after the pressure drops to 60 Pa;

[0029] (3) Freeze-drying: Slowly pressurize the freeze-drying chamber to normal pressure and then turn on the refrigeration. When the temperature of the cold trap is lower than -35°C, keep the normal hot plate to raise the temperature...

Embodiment 3

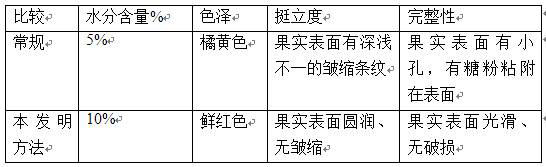

[0031] comparative test

[0032]

[0033] The wolfberry product produced by the method of the invention has moderate water content, bright red color, clean fruit surface, no sugar powder adhesion, and complete fruit shape, round, smooth, and no shrinkage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com