Optical fiber sensing technology and system for monitoring deformation of geomembrane anti-seepage earth-rockfill dam

A geomembrane, earth-rock dam technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as the results and examples of the fracture opening of useless geomembrane joints, and achieve rapid performance improvement, scientific and technological level, and improvement. Effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

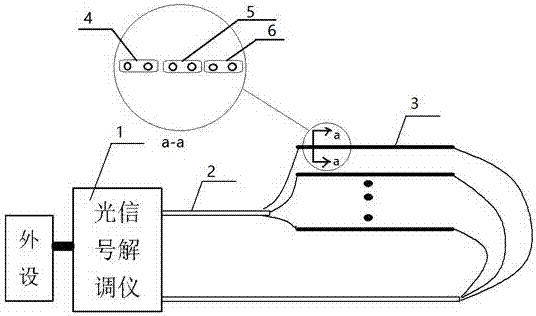

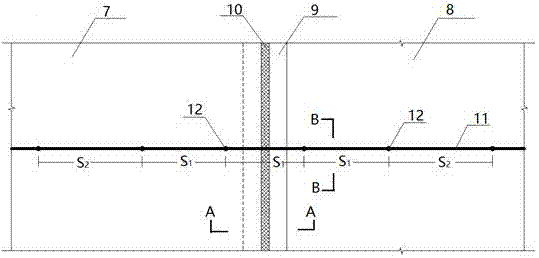

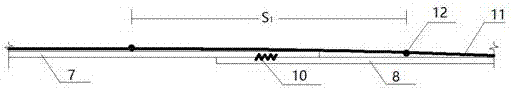

[0063] (1) Laying of the sensing fiber

[0064] After the PE geomembrane welding operation is completed, according to the layout design drawing of the optical fiber sensing network of the geomembrane anti-seepage system, on the surface of the geomembrane, scribe the consolidation point of the sensing fiber; Moderately shaved; unfold the sensing fiber and lay it in place according to the scribe line (see Figures 2-4).

[0065] (2) Consolidation and positioning process of sensing fiber

[0066] Using a quantitative tensile force, the optical fiber is straightened to generate and maintain a certain initial tensile strain during the consolidation operation. The initial tensile strain of the three sensing fibers should be:

[0067] ●SM tight-buffered fiber——200~600με

[0068] ●Carbon coated SM fiber——300~800με

[0069] ●Fluorinated POF fiber——1000~2000με

[0070] To this end, optical signal demodulators such as BOTDR and OTDR are used in advance to detect the straightened optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com