Long-distance-disassembling-assembling sword-type mechanical arm

A manipulator and long-distance technology, applied in the direction of sampling device, etc., can solve the problems of heavy and laborious operation, falling off of sword-type manipulator trigger, difficulty in replacing spring failure, etc., and achieve the effect of light and labor-saving operation, enlarged stroke, and convenient long-distance disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

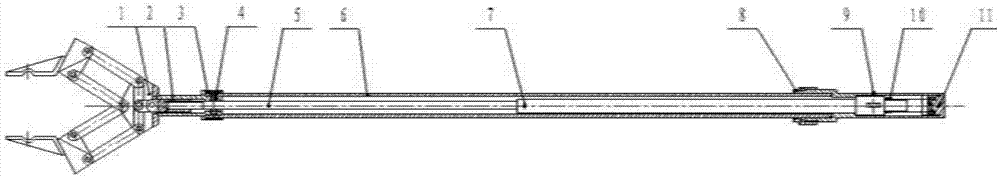

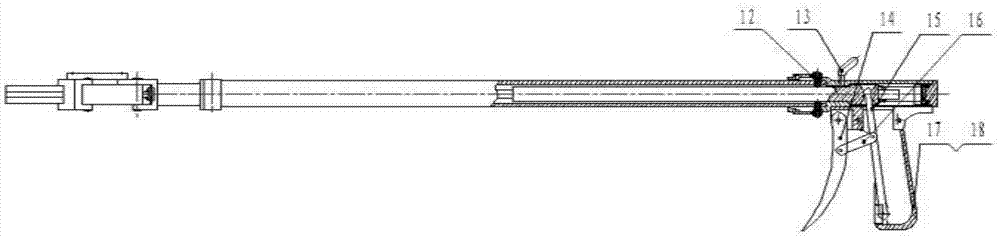

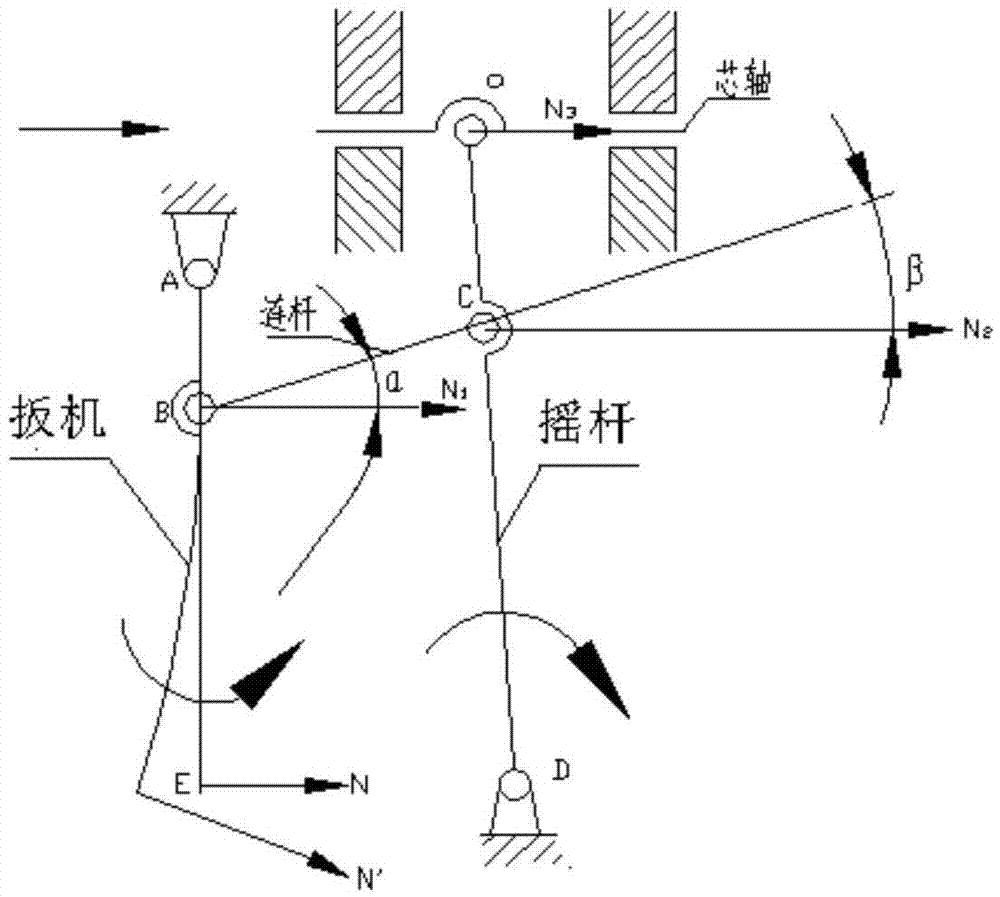

[0015] Such as figure 1 — image 3 As shown, the long-distance removable sword-type manipulator of the present invention includes a clamp 1, a nut rod 2, a polytetrafluoroethylene ring 3, a countersunk screw 4, a guide rod 5, a sleeve I6, a mandrel 7, a nut 8. Sleeve II 9, compression spring 10, spring seat 11, cross recessed pan head screw 12, locking screw 13, trigger 14, rocker 15, connecting rod 16, left half handle 17, right half handle 18;

[0016] The inside of the clamp 1 is connected to the nut rod 2 through rivets, and the outside of the clamp 1 is connected to the sleeve I6 with the countersunk screw 4. The polytetrafluoroethylene ring 3 covers the outside of the countersunk screw 4 to protect the countersunk screw 4 from falling off. One end of the guide rod 5 is connected to the nut rod 2 by a threaded rod, and the other end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com