Automatic seawater sample filtration and back-purge device

A technology of automatic filtration and backwashing, which is used in test water, preparation of test samples, and material inspection products, etc., can solve the problems affecting human beings' ability to monitor the marine environment, high attendance costs, and high operational risks, and reduce The effect of operation risk, reduced work intensity, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

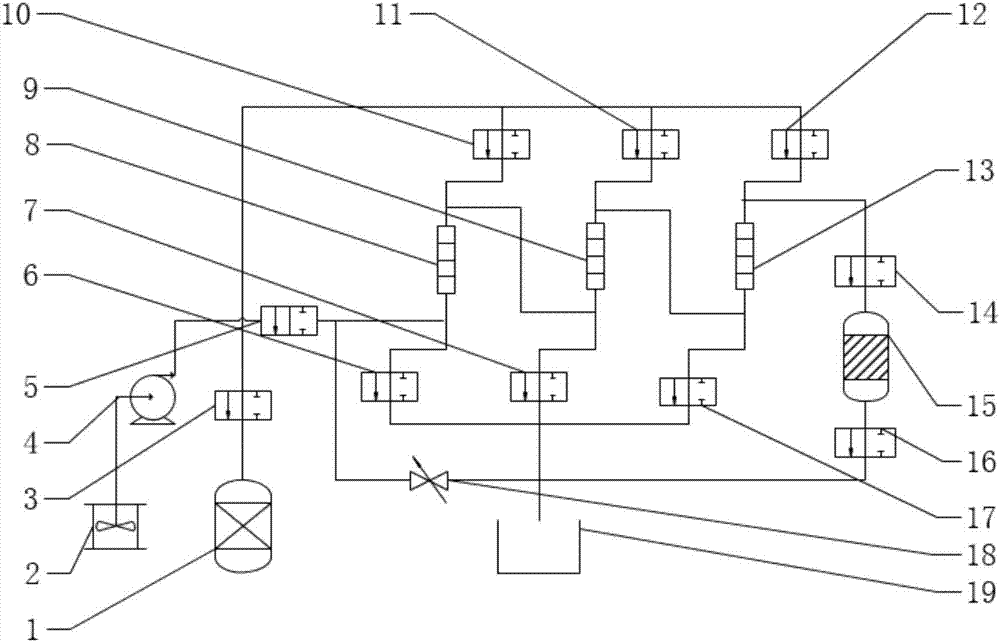

[0026] In this example, see Figure 1~3 , an automatic filtration and backwashing device for seawater samples, mainly including two parts: an automatic seawater filtration system and a pipeline backwashing system, which are respectively controlled by the main control system, as follows:

[0027] The automatic seawater filtration system mainly includes a water collection device 2, a diaphragm pump 4, a graded filtration device composed of different filter elements with a porosity range of 0.45-100 μ in series, a nutrient salt detector 15, a waste liquid pool 19 and a series of solenoid valves. The water outlet of the water collection device 2 is communicated with the suction port of the diaphragm pump 4, and the sea water sample can be sucked and transported by the water collection device 2 by the diaphragm pump 4, at least between the water outlet of the diaphragm pump 4 and the waste liquid pool 19 The water sample filtration and detection pipeline is set up, and the water sa...

Embodiment 2

[0045] This embodiment is basically the same as Embodiment 1, especially in that:

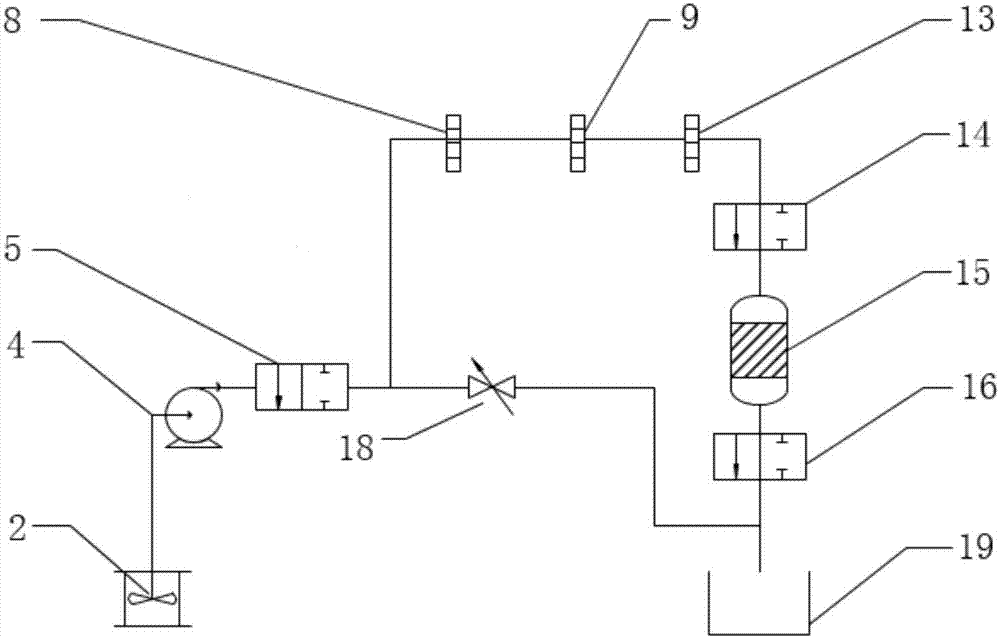

[0046] In this example, if Figure 4 As shown, in the automatic seawater filtration system, there is also an auxiliary diaphragm pump connected with the signal of the main control system. The auxiliary diaphragm pump is used as the second water pump, and its pipeline connection mode is exactly the same as that of the diaphragm pump 4, so that The water outlet of the water sampling device 2 communicates with the suction port of the auxiliary diaphragm pump, and the auxiliary diaphragm pump can also absorb and transport seawater samples through the water sampling device 2 . Two water pumps are installed in the water distribution pipeline in this implementation. When the water supply of the first water pump is insufficient, the second water pump is turned on, which provides guarantee for the stable operation of each detection system of water samples, forms an effective redundancy mechanism, and pr...

Embodiment 3

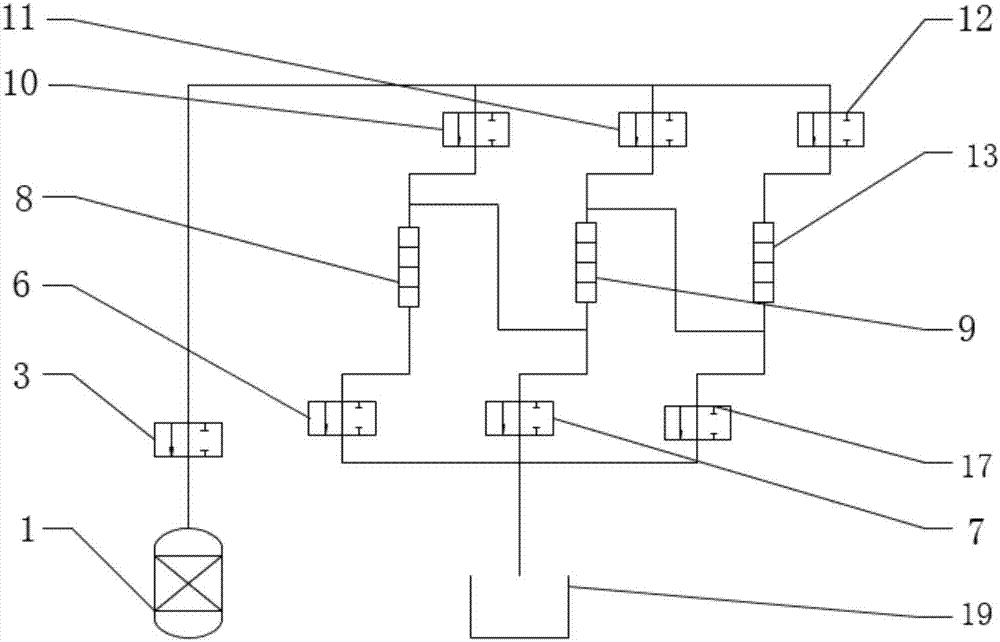

[0048] This embodiment is basically the same as the previous embodiment, and the special features are:

[0049]In this embodiment, in the pipeline backwashing system, the nutrient salt detection pipeline composed of the second solenoid valve 14, the nutrient salt detector 15 and the third solenoid valve 16 in series can also be cleaned, that is, by controlling the corresponding The solenoid valve of the ozone generator 1 is used to flush the nutrient analyzer 24 with the cleansing water provided by the outlet pipe of the ozone generator 1, and to wash away the attachments on the inner wall of the nutrient salt detection pipeline and the inner wall of the water passage chamber of the nutrient salt detector 15. To waste liquid pool 19. When cleaning the nutrient salt detection pipeline, open the ozone generator 1, the solenoid valve 3 of the washing water main pipe, the sixth solenoid valve 12, the second solenoid valve 14 and the third solenoid valve 16, and the water flow dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com