Ultrasonic water-logging testing and positioning drive device for small pipeline

A water immersion ultrasonic, positioning-driven technology, applied in the fields of nuclear reactor monitoring, reactor, nuclear power generation, etc., can solve the problems that affect the test results, cannot guarantee the probe fit, and the external environment dose rate is too high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

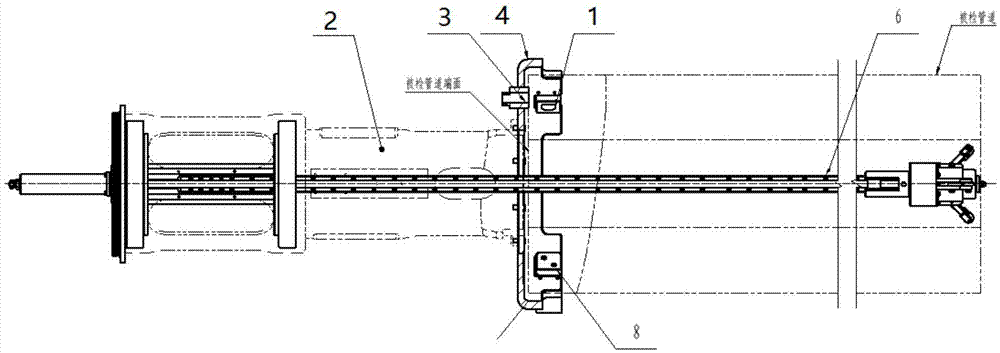

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

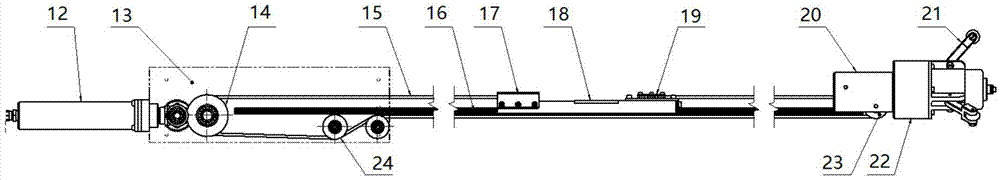

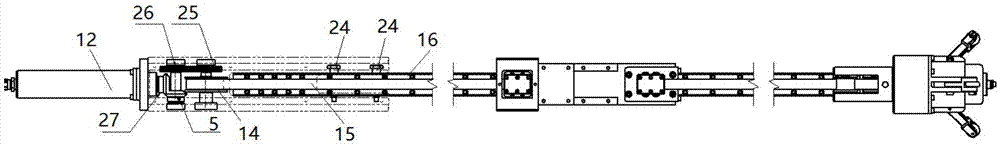

[0028] A schematic diagram of the installation of the axial assembly 6 as shown in FIG. 1 .

[0029] One end of the front support mandrel 20 is installed in the front support sleeve 22 through a bearing, so the front support mandrel 20 can rotate relative to the front support sleeve 22 . A front support leg 21 is installed on the front support sleeve 22, and the front support leg 21 can be opened or recovered in a pneumatic manner, and the front support leg 21 is opened synchronously to ensure the coaxiality of the inspection device and the pipeline. The driven synchronous pulley 23 is fixed on the front supporting spindle 20 .

[0030] A first intermediate gear 26 , a second intermediate gear 25 , a driving bevel gear 27 , a driven bevel gear 5 , and a driving synchronous pulley 14 are installed in the axial assembly base 13 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com