Bundle-type catalyst for oxidation of methanol and its combined structure

A technology for methanol oxidation and combined structure, applied in the field of packaged catalysts, can solve the problems of back-mixing of oxidation reaction materials, single and extensive physical structure of oxidation catalysts, turbulent flow, etc., so as to reduce impurities, improve distribution shape and flow mode, and improve product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples are only examples for clearly illustrating the present invention, rather than limiting the implementation of the present invention. For those of ordinary skill in the art, on the basis of the following descriptions, other different forms of changes or changes can also be made, and these obvious changes or changes that belong to the spirit of the present invention are still within the protection scope of the present invention middle.

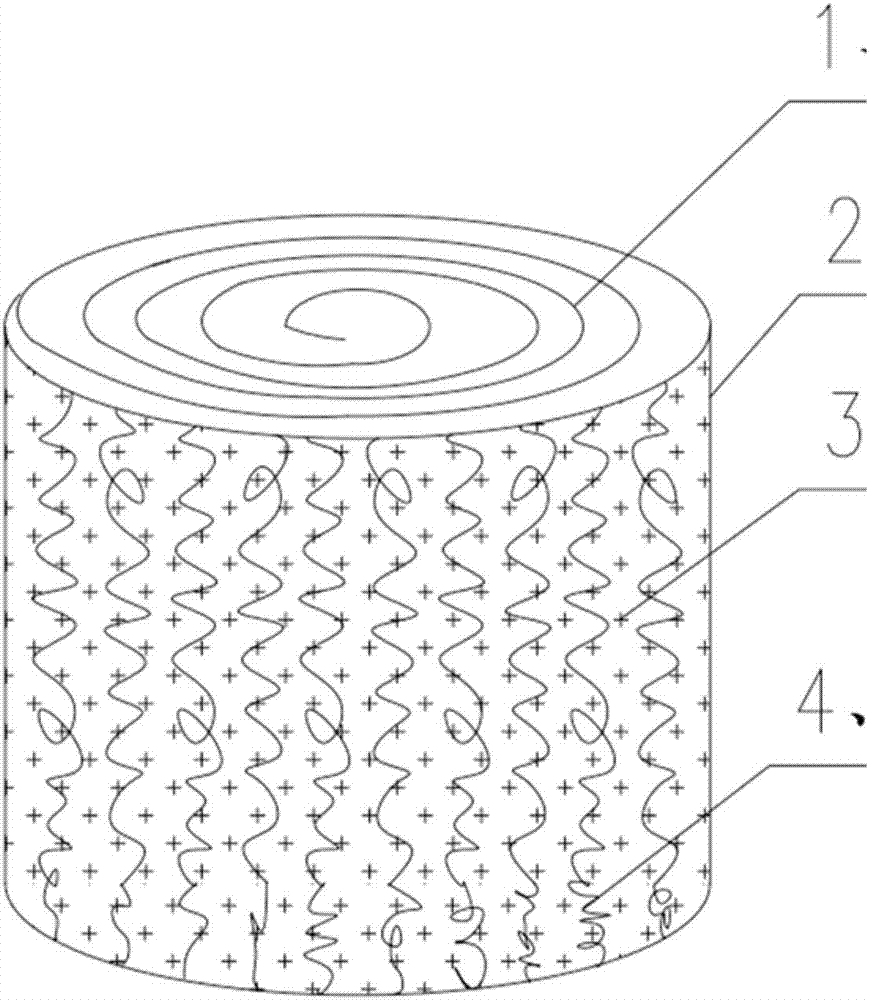

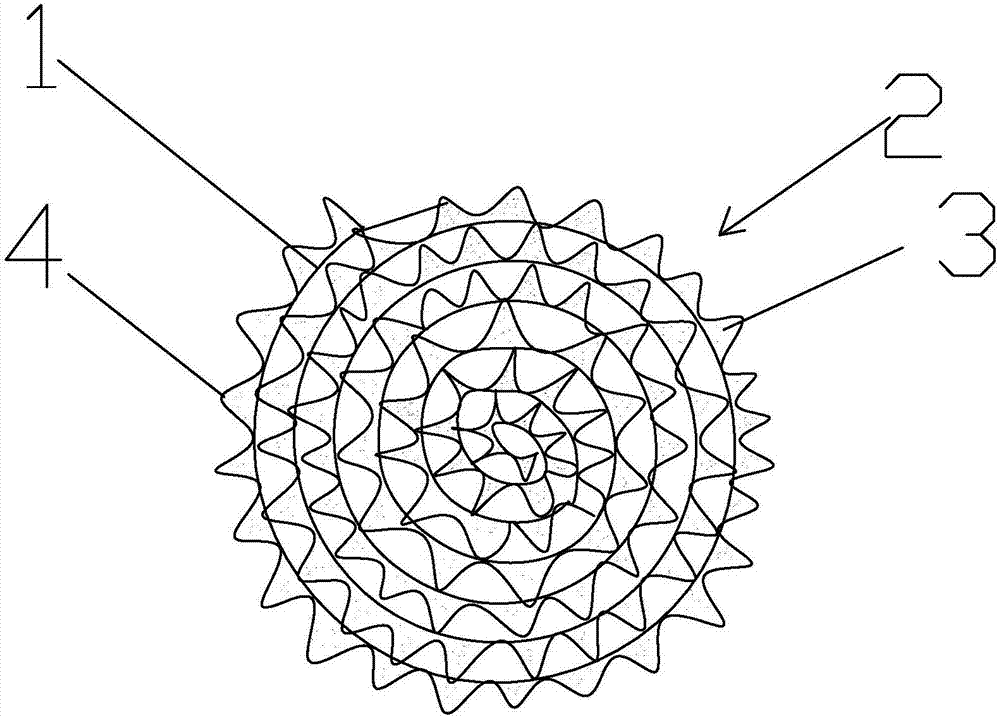

[0027] Such as figure 2 As shown, the present invention is a packaged catalyst 2 for methanol oxidation, which includes a stainless steel corrugated wire mesh 4, an active catalyst 3, and a flat wire mesh 1, and the active catalyst 3 is evenly distributed on the flat wire mesh 1 In the above, after the stainless steel corrugated wire mesh 4 and its tiled superimposition cover the active catalyst 3, the edge is closed, and one end is used as the axis to make a bundled catalyst 2; the active catalyst 3 is a granular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com