Collection and electrolysis system for deep sea hydrothermal fluid metal sulfide

A technology of metal sulfide and electrolysis system, which is applied in the field of deep-sea hydrothermal metal sulfide collection electrolysis system, can solve the problems of destroying biological ecological communities in hydrothermal areas, recycling, high smelting costs, high mining costs, etc., to alleviate global warming threats, reduce transportation costs, and reduce the effects of mining and smelting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

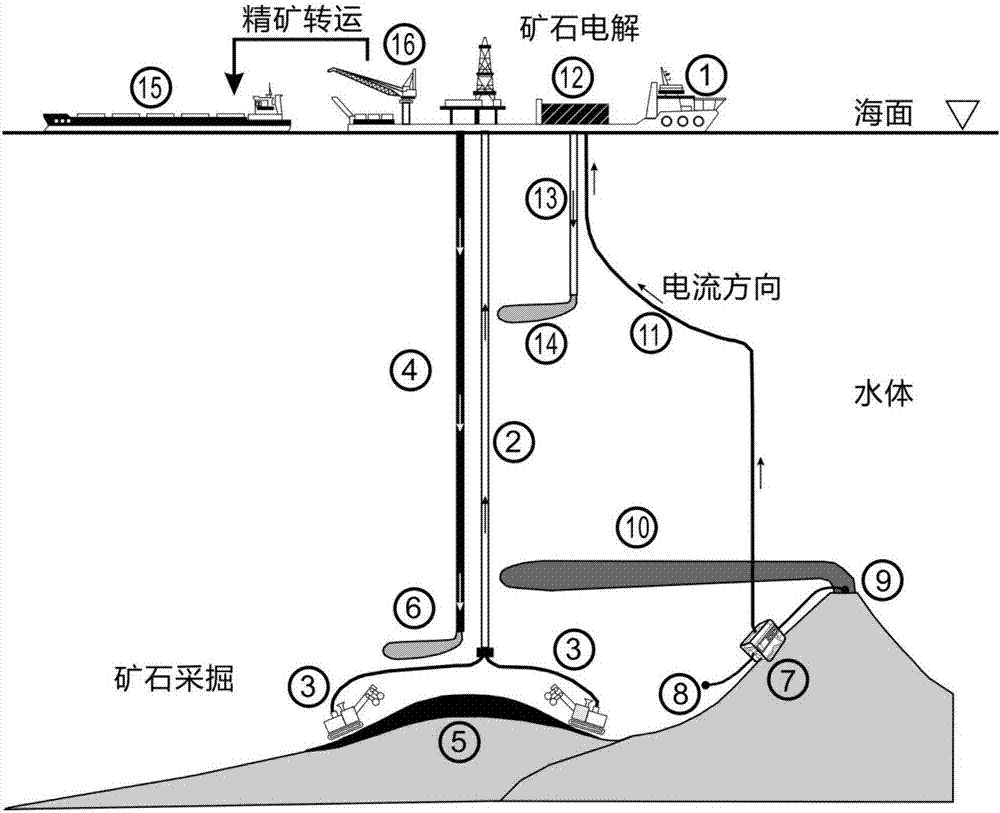

[0018] Such as figure 1 As shown, this embodiment provides a deep-sea hydrothermal metal sulfide collection and electrolysis system, which includes three functional units. The first functional unit is the ore mining and conveying unit, which includes the following parts: mining refining ship 1 (can also be a semi-submersible platform), ore conveying pipeline 2, mining robot 3, mining return water discharge pipeline 4. The second functional unit is the use of thermoelectric power generation and electrolysis of sulfide units, including the following parts: thermoelectric generator 7, hot end of thermoelectric generator 9, cold end of thermoelectric generator 8, cable 11, metal sulfide electrolytic cell 12 , Electrolysis wastewater discharge pipeline 13. The third functional unit is the concentrate transfer unit, which includes a transport ship 15 and a transfer crane 16.

[0019] A number of mining robots 3 are arranged on the metal sulfide deposit 5. The mining robot 3 moves on ...

Embodiment 2

[0026] The difference between the deep-sea hydrothermal metal sulfide collection and electrolysis system in this embodiment is that the thermoelectric generator 7 is connected to the mining robot 3 via a cable 11, and the electric energy of the thermoelectric generator 7 is supplied to the mining robot 3 Use to greatly reduce production costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com