Piston engine system and control method thereof

A technology of piston engine and turbocharger, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., can solve the problem of increased power consumption of the impeller in the latter stage and the inability to guarantee the output of the latter two stages of turbines, so as to reduce the power consumption. power, increase power output, and reduce fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

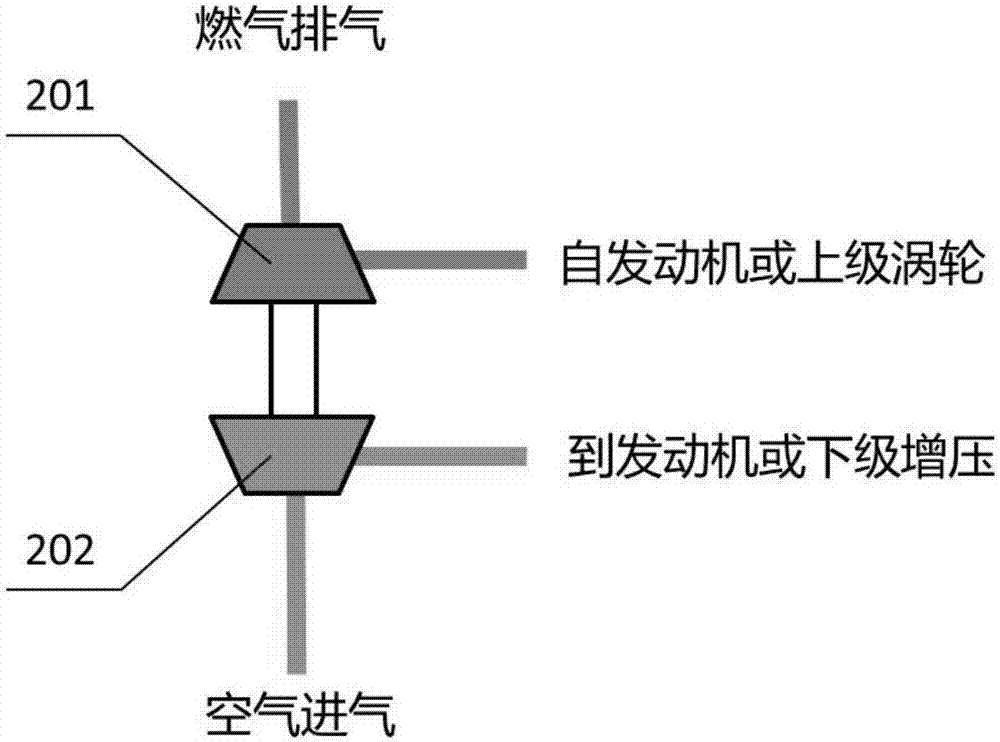

[0033] like figure 1 As shown, the single-stage turbocharger used in the present invention is composed of a centrifugal impeller 202 and a centripetal turbine 201 coaxially in a back-to-back manner. The air is axially intake and radially exhausted, and enters the piston engine or the lower stage supercharger; the gas is radially intaked and axially exhausted, and the gas comes from the piston engine after combustion or after passing through the upper stage turbine.

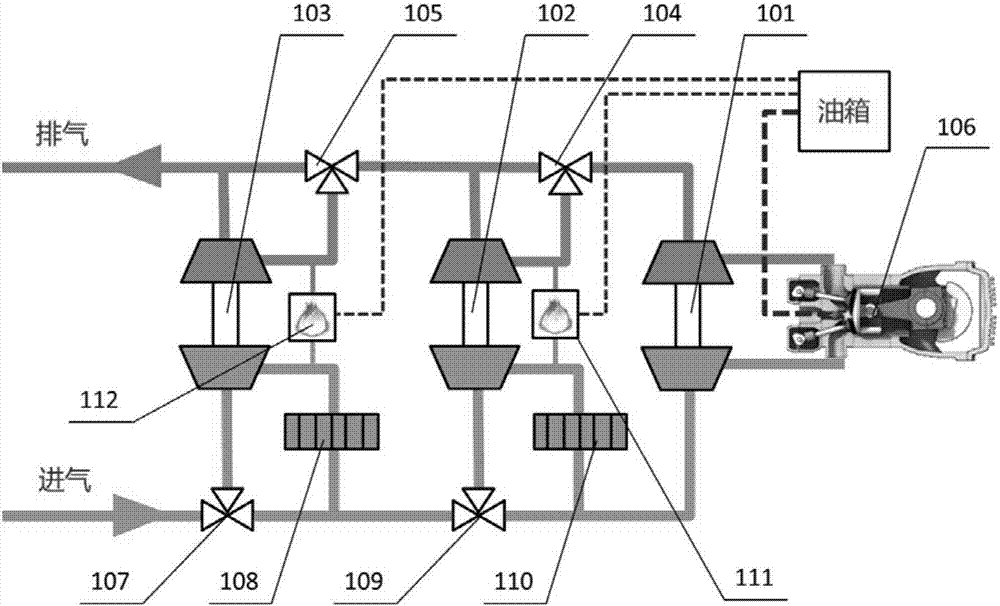

[0034] like figure 2As shown, the piston engine system of the present invention applied to a high-altitude long-endurance aircraft includes a grade I turbocharger 101, a grade II turbocharger 102, a grade III turbocharger 103, and a grade II gas three-way valve 104. , Class III g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com