Liquefied natural gas pre-refrigeration agent compressing and skid-mounted packaging module

A technology of liquefied natural gas and pre-refrigerant, applied in the directions of liquefaction, refrigeration and liquefaction, cold treatment separation, etc., can solve the problems of troublesome cleaning, burnout equipment, slow heat dissipation, etc. The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

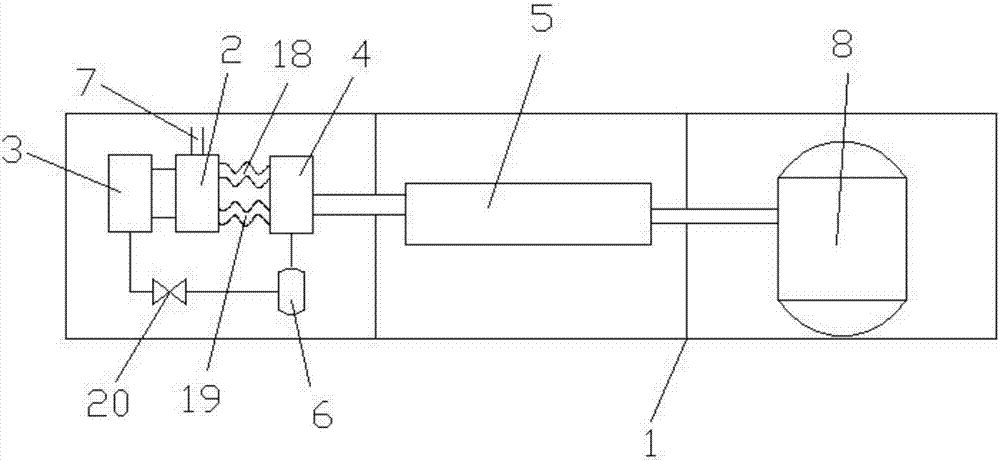

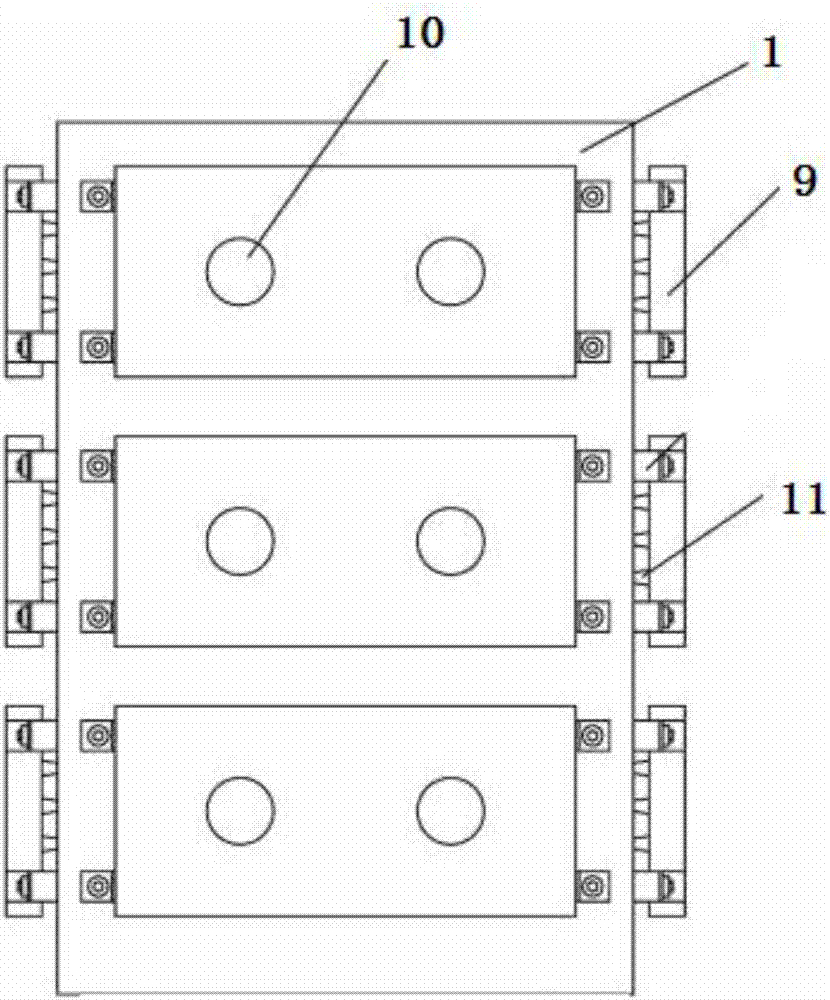

[0032] Refer to attached figure 1 As shown, a pre-refrigerant compression skid-mounted module for liquefied natural gas provided by the present invention includes a cavity housing 1, and the housing 1 is provided with a pre-refrigerant compressor 2, a compressor lubrication system 3, a lubrication The oil cooling heat exchanger 4 and the compressor lubricating oil fine separator 6; also includes a pre-refrigerant return pipe 7, the pre-refrigerant flows into the pre-refrigerant inlet of the pre-refrigerant compressor 2 after passing through the pre-refrigerant return pipe 7, After being processed, it flows out from the pre-refrigerant outlet of the pre-refrigerant compressor 2, flows into the lubricating oil cooling heat exchanger 4, and flows into the pre-refrigerant storage tank 8 after being cooled.

[0033] Wherein, the function of the pre-refrigerant compressor 2 is to compress and lower the temperature of the pre-refrigerant returned from the pre-cooling module after pre...

Embodiment 2

[0042] On the basis of Embodiment 1, the purpose of this embodiment is to remove the granular impurities in the housing 1, keep the housing 1 clean, and prevent impurities from affecting the operation of natural gas liquefaction or other equipment.

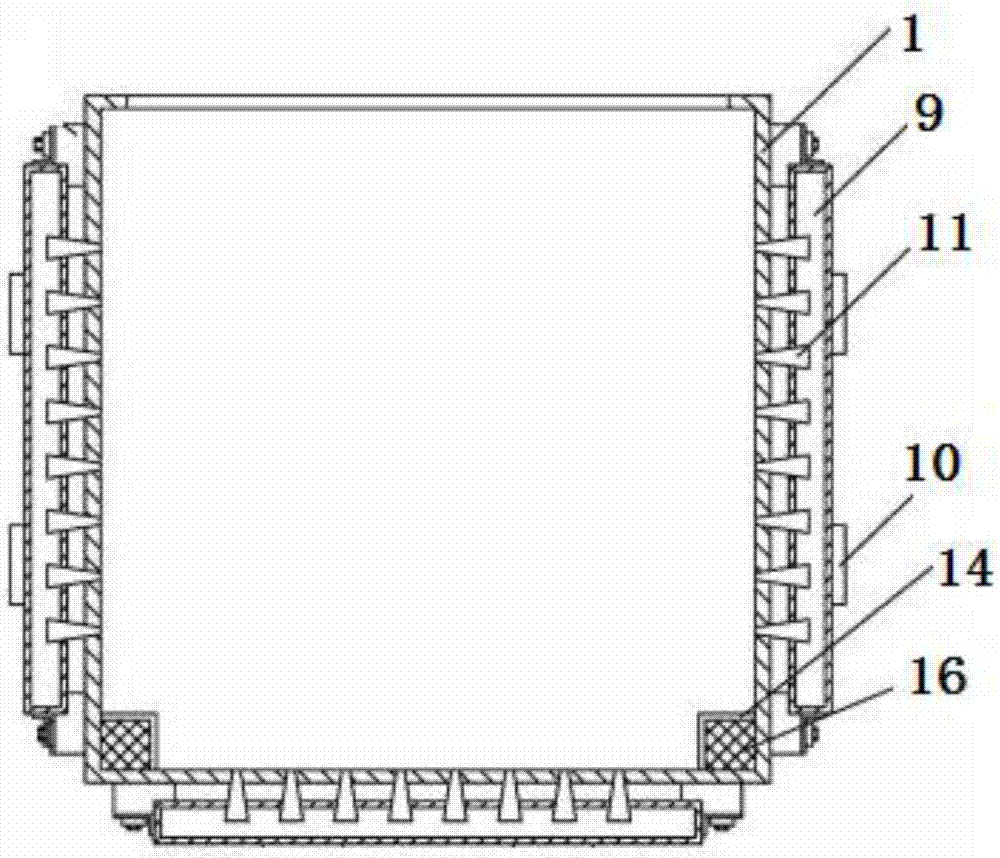

[0043] On the basis of embodiment 1, with reference to the attached image 3 As shown, a pair of columnar containers 14 for removing particulate matter impurities that are kept at an angle of 90 degrees to each other are arranged in the housing 1;

[0044] Further, refer to the attached Figure 7 As shown, there are more than two through-holes 15 for feeding airflow on the columnar container 14 for removing particulate impurities. Through the through hole 15, the air flow in the cylindrical container 14 for removing particulate impurities is accelerated.

[0045] Refer to attached Figure 7 As shown, further, in order to facilitate dust removal and absorption of impurities, the columnar container 14 for removing particulate imp...

Embodiment 3

[0049] In order to ensure the cleanliness and purity of the pre-refrigerant entering the pre-refrigerant storage tank 8, in this embodiment, a pre-refrigerant filter is provided between the lubricating oil cooling heat exchanger 4 and the pre-refrigerant storage tank 8 device 5.

[0050] Further, in order to avoid the impact of the compressed air pulse in the pre-refrigerant compressor 2, the impact of the unstable air flow on the lubricating oil cooling heat exchanger 4 is reduced, and the service life of the lubricating oil cooling heat exchanger 4 is improved. The refrigerant compressor 2 and the lubricating oil cooling heat exchanger 4 are connected through a pre-refrigerant elbow 18 and a lubricating oil elbow 19 .

[0051] In this embodiment, the curved pipe is set, and compared with the straight pipe connection, the buffer is added, so that whether it is pre-refrigerant or lubricating oil, it will flow into the lubricating oil cooling heat exchanger 4 after buffering, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com