On-line monitoring system and method for settlement of tracks in automatic container yard of harbor

A container yard and monitoring system technology, which is applied in the field of on-line monitoring system for track settlement in port automated container yards, can solve the problems of large impact on production scheduling, low efficiency, intermittent monitoring data, etc., achieve good market application space, and improve detection Efficiency, the effect of reducing the cost of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

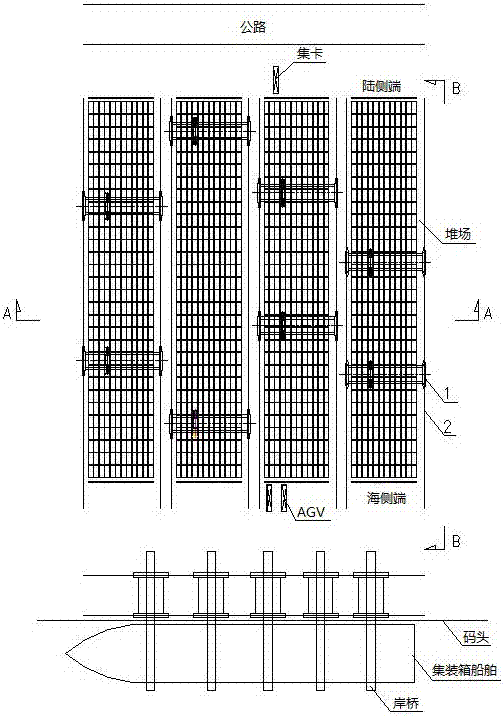

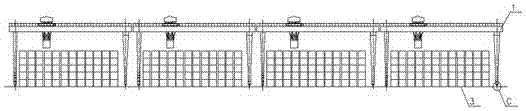

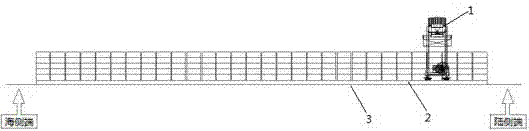

[0023] see figure 1 , figure 2 with image 3 , The port automated container yard is arranged with rails perpendicular to the wharf, and multiple quay bridges are installed on the wharf to operate the container ships berthing at the front of the wharf. The container is transported to the rear yard by AGV, and the rail-mounted gantry crane 1 is arranged on the yard for operation. The track 2 is installed on the storage yard, and the rail-mounted gantry crane 1 walks on the track 2. The sea side of the yard is the AGV parking area, and the land side is the truck parking area. The entire yard adopts unmanned operation.

[0024] The on-line monitoring system for track settlement of port automation container yard consists of three parts, the first part is the on-site monitoring system, the second part is the data wireless transmission system, and the third part is the rear monitoring system.

[0025] see Figure 4 , Figure 5 , Image 6 with Figure 7 , The on-site monitori...

Embodiment 2

[0029] Specific monitoring methods: see Image 6 with Figure 8 , when the yard ground 3 settles, the track 2 installed on the yard ground 3 will settle synchronously, and the reference point static level 4 at the seaside end of the track 2 is still at the initial setting position, while it is based on the same foundation as the track 2 and arranged on Each static level 51, 52 ... 5n-2, 5n-1, 5n in a row of static levels 5 on the side of the track 2 will settle, and each static level 51, 52 ... 5n-2, 5n- 1, 5n Measure the relative height difference of the static level 51, 52... 5n-2, 5n-1, 5n of each monitoring point at any time relative to the reference point static level 4, and the corresponding position of the monitoring point can be obtained. Settlement value of track 2; and real-time comparison with the tolerance of rail-mounted gantry crane 1. When the settlement of track 2 is found to be close to the tolerance of rail-mounted gantry crane 1, an early warning will be gi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com