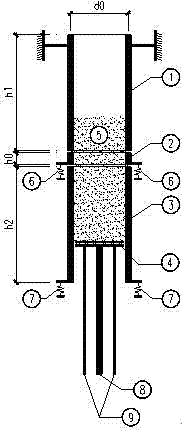

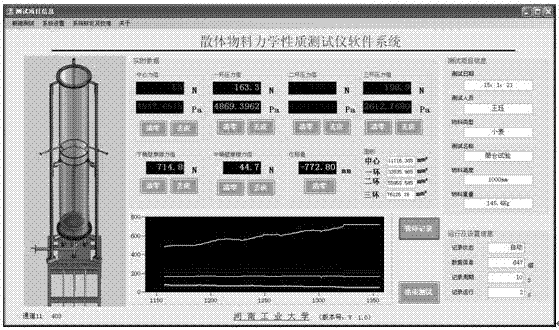

Test method and device measuring silo bulk material pressure and sidewall frictional force

A test method and technology of a test device, which are applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problem that there is no technology and method for directly measuring the friction force of the side wall, and it is impossible to truly reveal the bottom pressure distribution, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

test approach 1

[0015] Step 1: Use the weights and the calibration module that comes with the test device to calibrate each pressure sensor, and at the same time confirm that the lifting system and data acquisition system of the device are operating normally;

[0016] Step 2: Move the bottom plate to the bottom of the lower cylinder, and reset the readings of each sensor of the test device to zero;

[0017] Step 3: The height of each grain loading can be set according to the test accuracy requirements. Generally, it is 1 / 10 to 1 / 20 of the total grain loading height H. The scale on the wall checks the flatness of the grain surface, measures and records the height of the grain pile at the same time, records the weight of the loaded grain, stands still for 1 to 2 minutes, records the pressure sensors of the middle cylinder, the pressure sensors of the lower cylinder, and the pressure sensors of each tray. And the readings of various sensors such as the base plate displacement sensor;

[0018] S...

test approach 2

[0025] Step 1: Same as test plan 1;

[0026] Step 2: Raise the bottom plate of the silo to the lowest point of the measuring unit ring in the middle section of the cylinder wall, and reset the readings of each sensor of the test device to zero;

[0027] Step 3: Fill the silo with grain and record the weight of the grain loaded. After reaching the expected amount of grain, use the scraper to level the grain in the bin, and use the ruler on the bin wall to check the flatness of the grain surface, and measure and record the height of the grain pile at the same time. Stand still for 1 to 3 minutes, during which the readings of each sensor in the initial state of the test were recorded several times, including the pressure sensor of the middle cylinder, the pressure sensor of the lower cylinder, the pressure sensor of the bottom plate tray and the displacement sensor of the tray;

[0028] Step 4: The bottom plate is slowly lowered step by step through the lifting screw, and each t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap