Vibration and non-linear inhibition method for piezoelectric positioning device

A positioning device and non-linear technology, applied in the direction of electric controller, non-electric variable control, controller with specific characteristics, etc., can solve the problem that the feedforward adjustment method depends on modeling accuracy, etc., achieve simple structure and realize integrated control , Good effect of robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

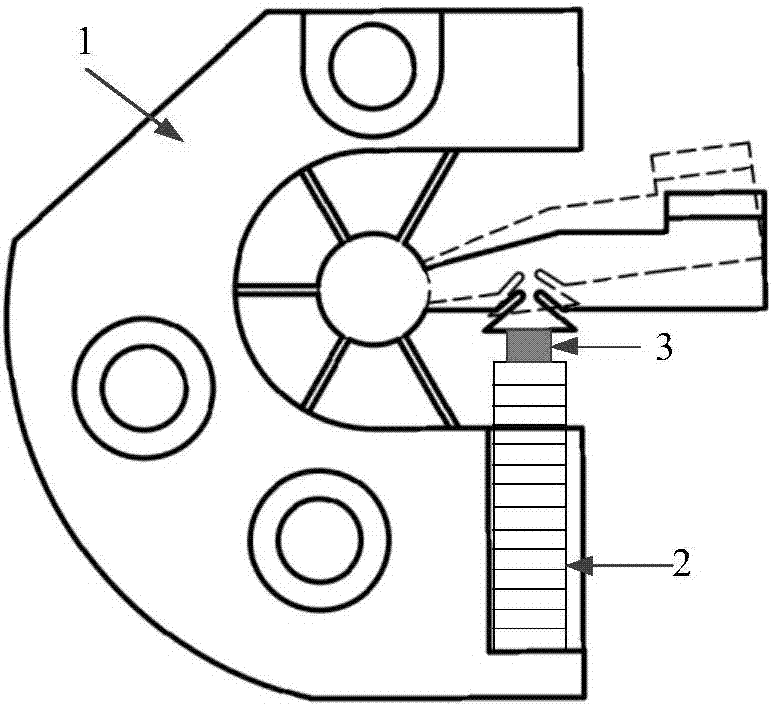

[0032] see Figure 1 to Figure 4 As shown, a vibration and nonlinear suppression method of a piezoelectric positioning device of the present invention comprises the following steps:

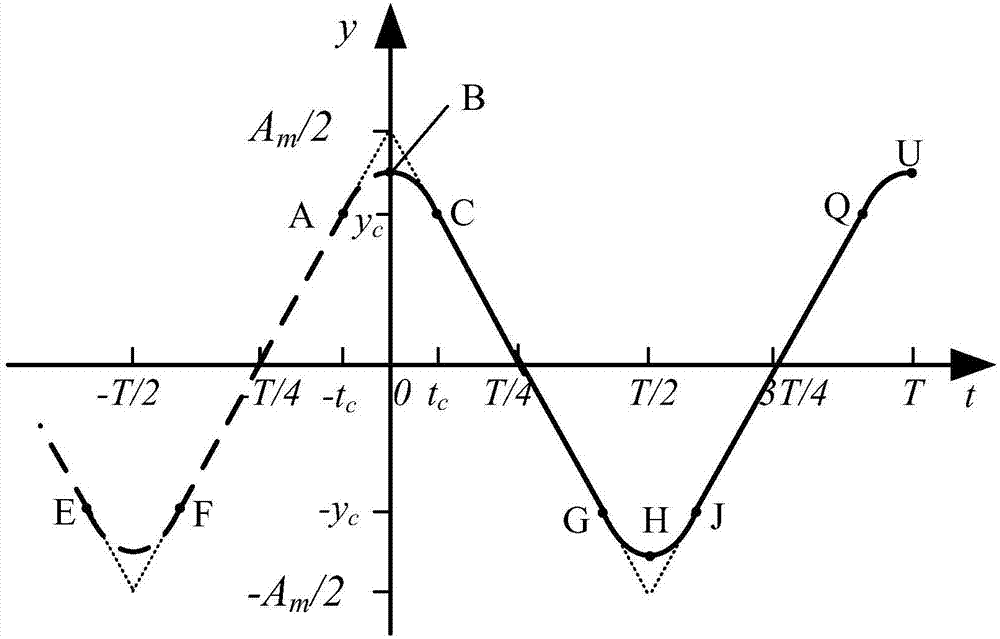

[0033] (1) Preprocessing the voltage signal of the input piezoelectric ceramic: segmentally optimizing the input triangular wave trajectory. The linear region remains unchanged, and the minimum acceleration criterion is used to smooth the waveform of the sharp point region of the signal waveform. On the basis of not changing the key characteristics of the signal, the suppression of high-order components in the frequency domain of the signal is realized.

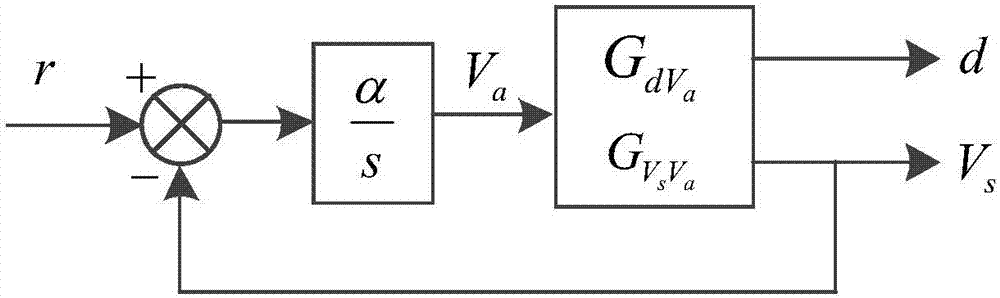

[0034] (2) The dynamic modeling of the piezoelectric positioning device is carried out to obtain the system stiffness, damping, natural frequency and the open-loop transfer function between the input voltage and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com