Production method for white tea cake

A production method and tea cake technology, which are applied in the direction of tea treatment before extraction, etc., can solve the problems of reducing the content of free amino acids, reducing the freshness, and darkening the color of the tea soup.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

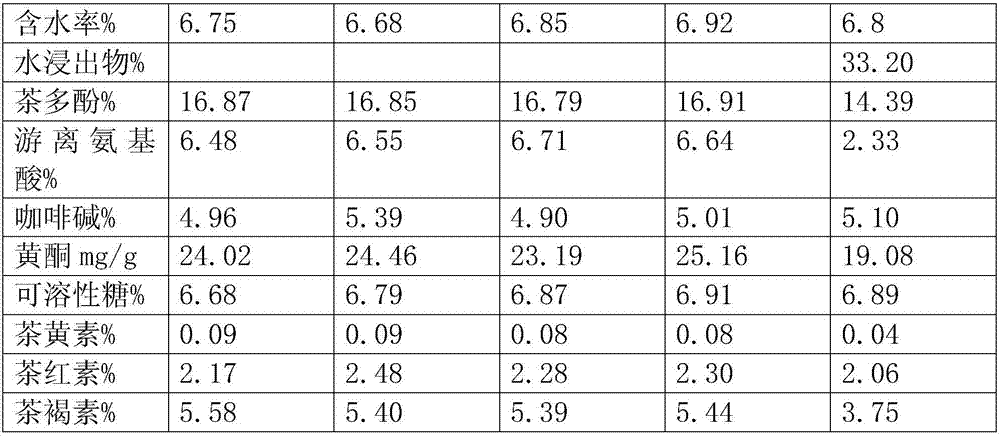

Examples

Embodiment 1

[0017] 1) Add water to the freshly picked white tea leaves (Shoumei) until the water content is 60%;

[0018] 2) Lay the tea leaves in 4 layers, with a layer height of 0.4cm, and control the temperature of the pile at 60°C until the moisture content is below 20%; Turn the tea; when the water content drops to 40%, turn the tea for the second time; when the water content drops to 30%, turn the tea for the third time;

[0019] 3) Molding the Odui tea leaves into tea cakes of predetermined shape, and drying until the moisture content of the leaves is below 7%.

Embodiment 2

[0021] 1) Add water to the freshly picked white tea leaves (Shoumei) until the water content is 65%;

[0022] 2) Lay the tea leaves in 5 layers of tea piles, with a layer height of 0.5cm, and control the temperature of the pile at 70°C until the moisture content is below 20%; during the pile process, when the moisture content drops to 55%, the first Turn the tea; when the water content drops to 45%, turn the tea for the second time; when the water content drops to 35%, turn the tea for the third time;

[0023] 3) Molding the Odui tea leaves into tea cakes of predetermined shape, and drying until the moisture content of the leaves is below 7%.

Embodiment 3

[0025] 1) Add water to the freshly picked white tea leaves (Shoumei) until the water content is 62%;

[0026] 2) Lay the tea leaves in 4 layers, with a layer height of 0.4cm, and control the temperature of the pile at 70°C until the moisture content is below 20%; during the pile process, when the moisture content drops to 50%, the Turn the tea; when the water content drops to 45%, turn the tea for the second time; when the water content drops to 30%, turn the tea for the third time;

[0027] 3) Molding the Odui tea leaves into tea cakes of predetermined shape, and drying until the moisture content of the leaves is below 7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com