Preparation technology of organic green tea

An organic green tea and a production process technology, applied in the field of green tea, can solve the problems of not long-lasting fragrance, insufficient aroma quality, heavy astringency, etc., and achieve the effects of yellow-green color, strong aroma and long-lasting aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

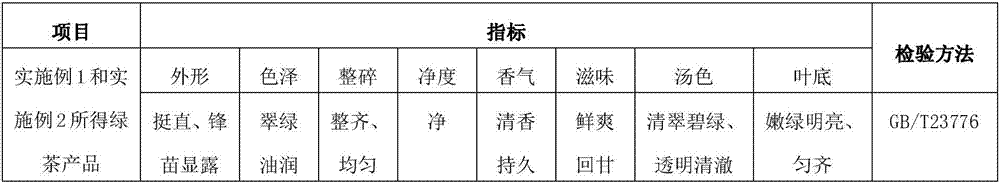

Examples

Embodiment 1

[0036] The manufacturing process of organic green tea, this process specifically comprises the following steps:

[0037] (1) Picking: pick fresh organic green tea leaves with one bud and one leaf or one bud and two leaves, put the picked tea leaves in a clean and breathable bamboo basket or bamboo grate, and put them in a cool and ventilated place for later use;

[0038] (2) Cleaning: Rinse the picked tea leaves twice with spiral water flow, put them in a bamboo grate to drain, and let the natural wind blow to the surface of the tea leaves without obvious water droplets; when washing, the amount of tea leaves and water is calculated as 1:12 in mass ratio ;

[0039] (3) Spreading: After the above-mentioned rinsed tea leaves are loosened, they are spread on a shelf in a cool and ventilated room. The thickness of the spread is 1.5cm, the room temperature is controlled at 15°C, and the humidity is controlled at 40%. Turn it over once, spread it for 4.0 hours, and the water conten...

Embodiment 2

[0046] The manufacturing process of organic green tea, this process specifically comprises the following steps:

[0047] (1) Picking: pick fresh organic green tea leaves with one bud and one leaf or one bud and two leaves, put the picked tea leaves in a clean and breathable bamboo basket or bamboo grate, and put them in a cool and ventilated place for later use;

[0048] (2) Cleaning: Rinse the picked tea leaves twice with spiral water flow, put them in a bamboo grate to drain, and let the natural wind blow to the surface of the tea leaves without obvious water droplets; when washing, the amount of tea leaves and water is calculated as 1.5:13 by mass ratio ;

[0049] (3) Spreading: Spread the washed tea leaves on a shelf in a cool and ventilated room after fluffing up. Turn it over once and spread it for 4.5 hours; the water content of the tea leaves after spreading is 88%;

[0050] (4) Finishing: Send the tea leaves that have been spread out into the drum-type greening mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com