Self sucking jet type high efficient degradation groove suitable for degrading COD

A self-priming jet type, high-efficiency technology, applied in dissolution, mixer with rotary stirring device, chemical/physical/physical-chemical stationary reactor, etc., can solve the problems of poor mixing effect, long time consumption, low processing capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

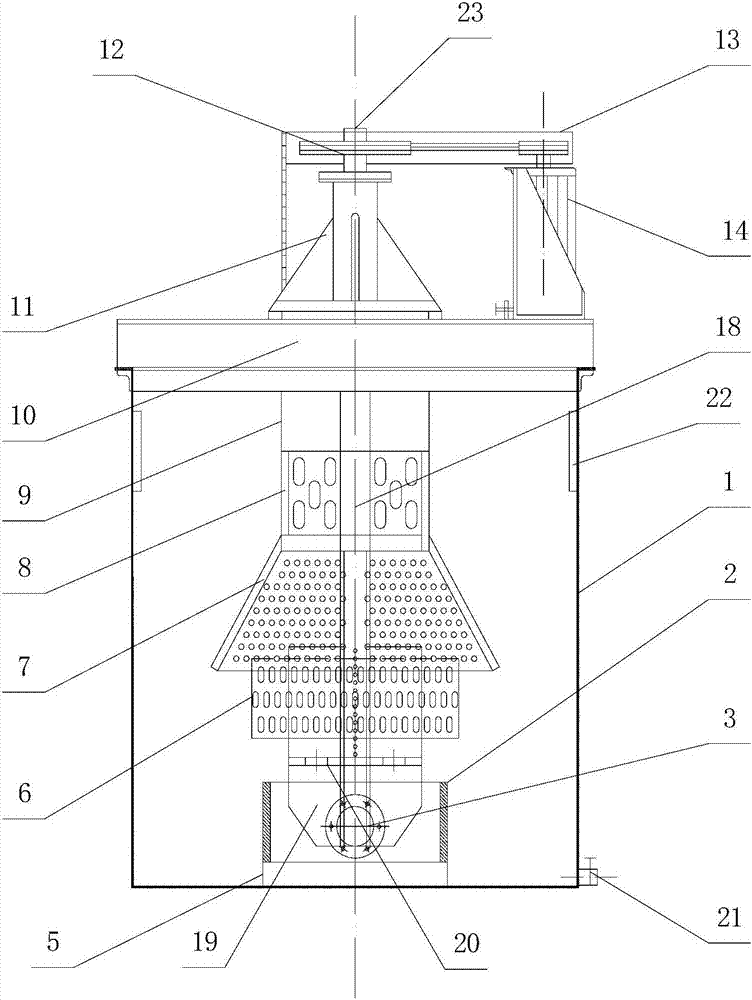

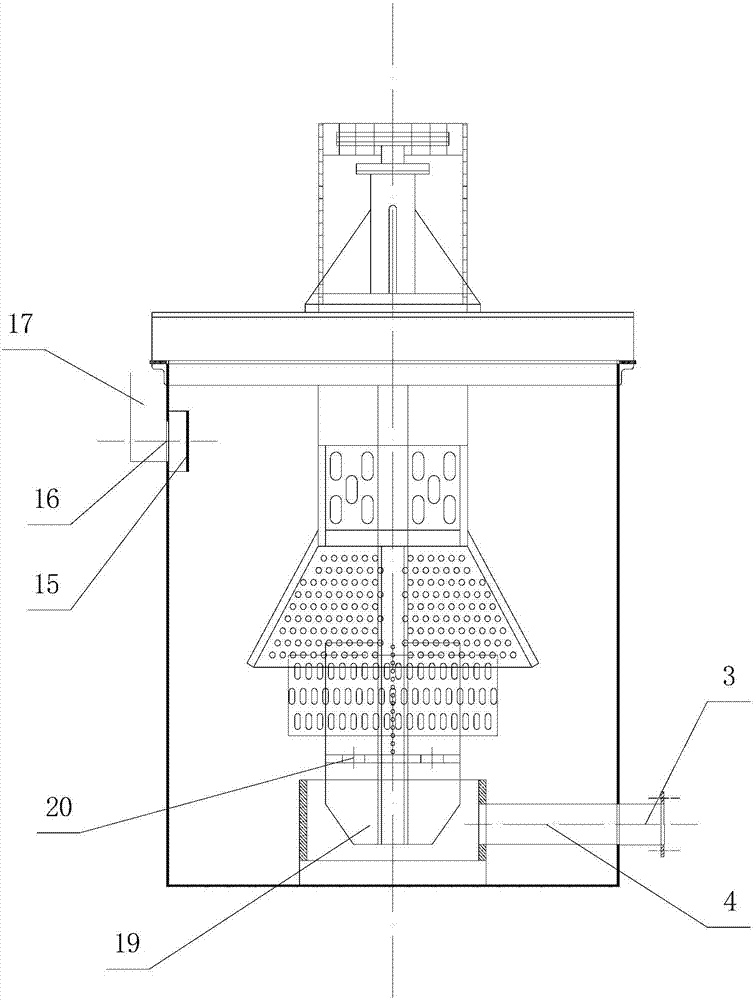

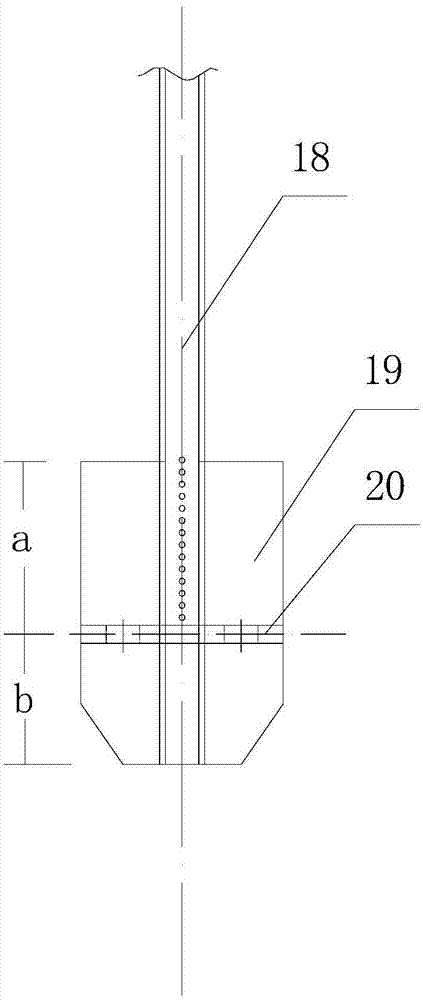

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a self-priming spray-type high-efficiency degradation tank suitable for degrading COD includes a tank body 1, a vertical guide tube 2, a slurry suction pipe 3, a slurry inlet 4, a connecting column 5, an air flow dispersion cylinder 6, Spray grid plate 7, upper deflector vertical tube 8, connecting rod 9, transmission frame 10, transmission base 11, driven wheel 12, protective cover 13, transmission motor 14, diversion partition 15, slurry outlet 16, overflow Launder 17, central hollow shaft 18, radial vanes 19, perforated vane partitions 20;

[0032]The cross section of the tank body 1 is circular or octagonal (the diameter of the tank body 1 is 500 mm to 15000 mm), and the bottom of the center of the tank body 1 is provided with a vertical guide tube 2 (the vertical guide tube 2 is The ratio of the diameter of 2 to the diameter of the tank body 1 is 1:2~3, such as 1:2, 1:2.5, 1:3, etc.), and the vertica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com