Four-shaft horizontal forming and bending machine for machining corrugated culvert pipe

A corrugated culvert, horizontal technology, applied in the field of four-axis horizontal corrugated culvert type bending machine, can solve the problems of high labor cost, low work efficiency, shortened product life, etc., achieve high work efficiency, reduce processing cost, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

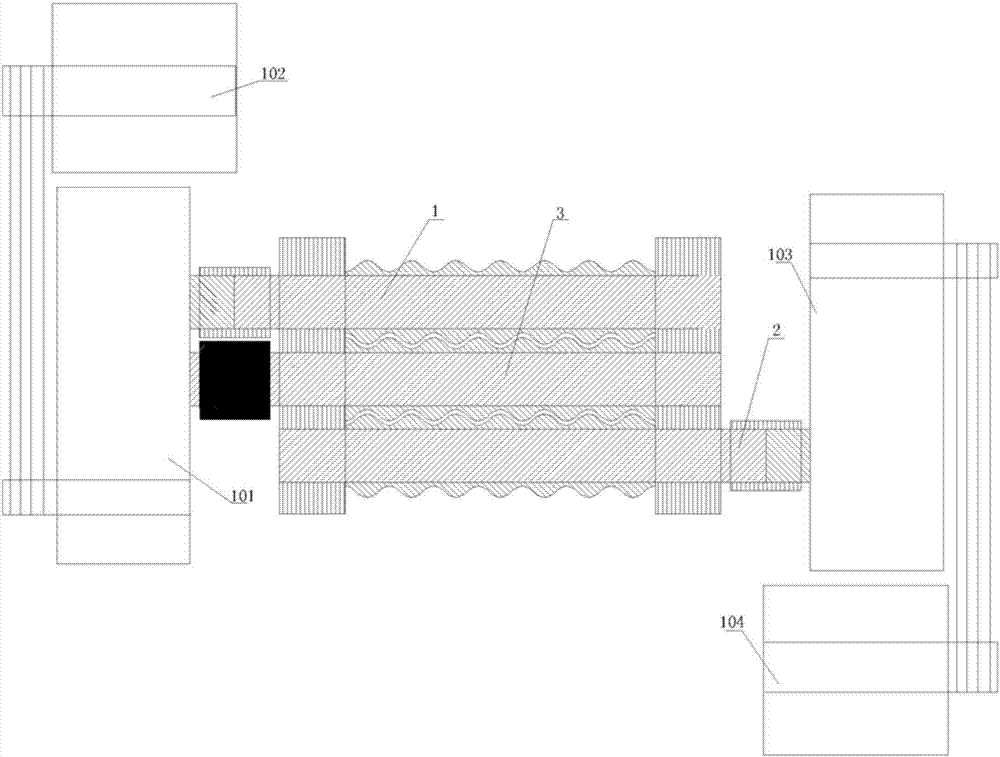

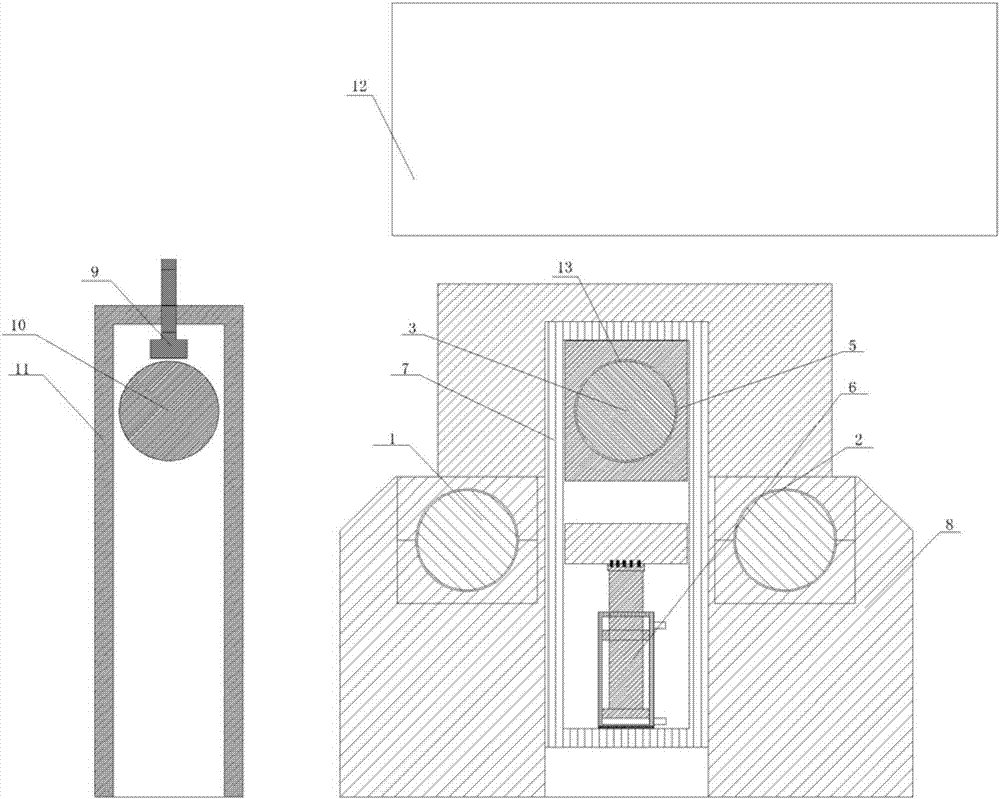

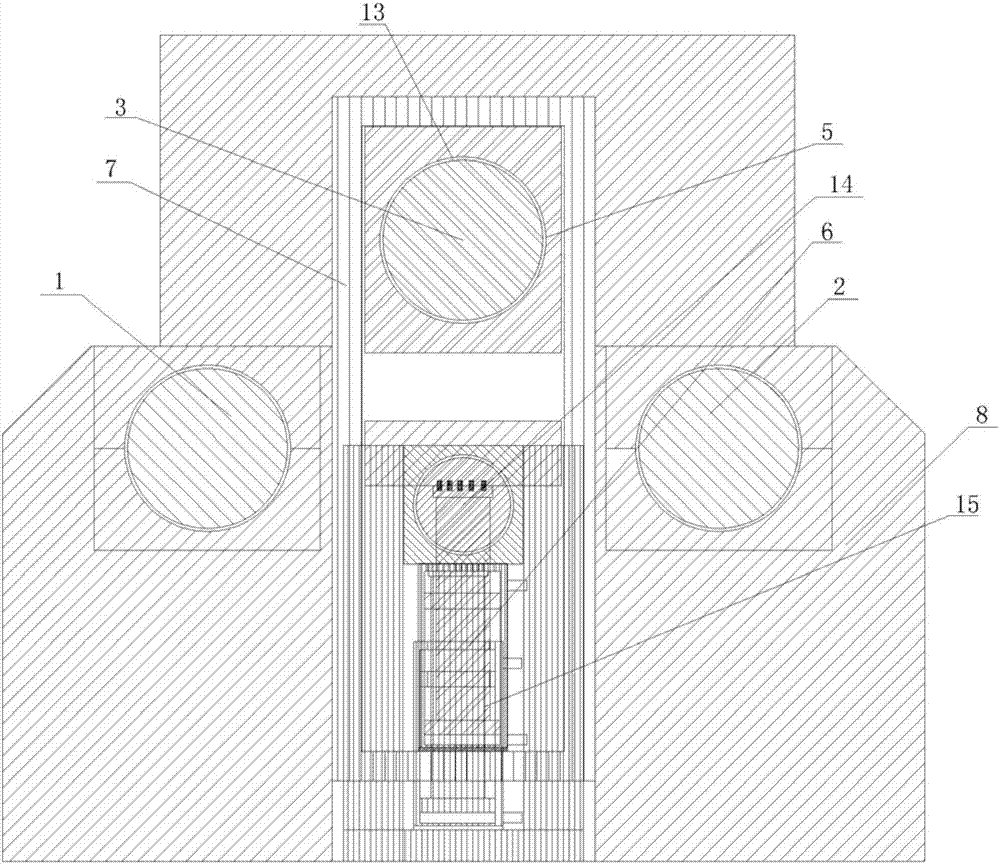

[0018] The present invention will be described in detail below with reference to the accompanying drawings. As shown in the drawings, the four-axis bending machine structure of the present invention includes a left reducer 101, a left motor 102, a right reducer 103, a right motor 104, an equipment base 105, a driving shaft A1, a driving shaft B2, and a passive forming shaft 3 , forming wheel 3.1, round steel pin 4, wear-resistant nylon sleeve 5, recoil hydraulic cylinder A6, tension frame 7, archway 8, lifting fulcrum 9, passive forming shaft head 10, lifting bracket 11, hydraulic pump station assembly 12 , two half-type spherical shaft head supports 13, forming shaft 14, left end wheel 14.1, right end wheel 14.2, recoil hydraulic cylinder B15, it is characterized in that the left reducer 101 is connected with the left motor 102, and the right reducer Machine 103 is connected with right electric motor 104, and drive shaft A1 is installed on the left reducer 101, and drive shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com