Elliptic grinding wheel finishing machine and finishing method

A grinding wheel dresser and elliptical technology, which is applied in the field of universal elliptical grinding wheel dresser, can solve the problems of high investment cost, difficult dressing of elliptical grinding wheel, and low precision, and achieve the effect of low cost investment, large market value and high dressing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

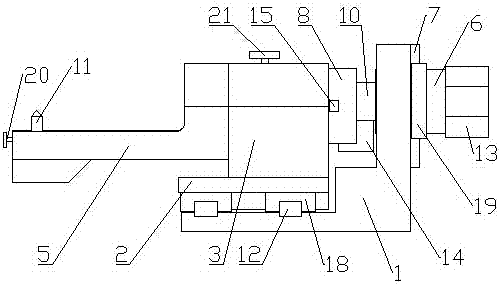

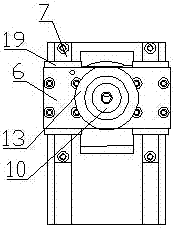

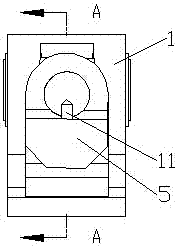

[0023] Embodiment 1: as Figure 1-7 As shown, a universal elliptical grinding wheel dresser includes a main frame 1, on which a base 3 is slidably connected through slide rails, the base 3 can slide back and forth on the main frame 1, and a first rotating shaft 4 is sleeved inside the base 3 , the first rotating shaft cooperates with the base 3, the left end of the first rotating shaft 4 is connected with a swing arm 5, the first rotating shaft 4 drives the swing arm 5 to rotate, the end of the swing arm 5 is movably connected with a trimming pen 11, and the swing arm 5 drives the trimming The pen 11 rotates; the right end of the main frame 1 slides to be provided with an up and down slider 6, and the up and down slider 6 moves up and down on the main frame 1, and the up and down slider 6 passes through the fixed groove on the main frame 1, and the up and down slider 6 is provided with The second rotating shaft 10, the second rotating shaft passes through the upper and lower s...

Embodiment 2

[0030] Embodiment 2: as Figure 8As shown, the dressing of the elliptical grinding wheel by the universal elliptical grinding wheel dresser: install the device on the grinding machine to make it well connected; then loosen the bolts between the locking piece and the T-block, and pass according to the long axis of the elliptical grinding wheel to be dressed. Adjust the gap between the T-shaped block on the second shaft and the zero alignment block with the upper and lower sliders, so that the center line of the second shaft and the center line of the first shaft are not on the same straight line. At this time, the distance between the second shaft and the zero alignment block The gap between them is 1 / 2 of the center distance of the major axis of the ellipse to be trimmed; adjust the up and down position of the trimming pen through the second fixed knob, and the eccentricity between the center of the trimming pen and the first rotating shaft is the ellipse to be trimmed. Short ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com