Thin film leveling guide roller mechanism

A guide roller mechanism and flattening technology, applied in the field of film flattening guide roller mechanism, can solve the problems of inability to completely solve the problem of wrinkling and shrinkage, reduce the film cooling shrinkage rate, and cannot remove wrinkles and flatten the film, and achieve ideal wrinkle and flattening effects. Smooth sliding and anti-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

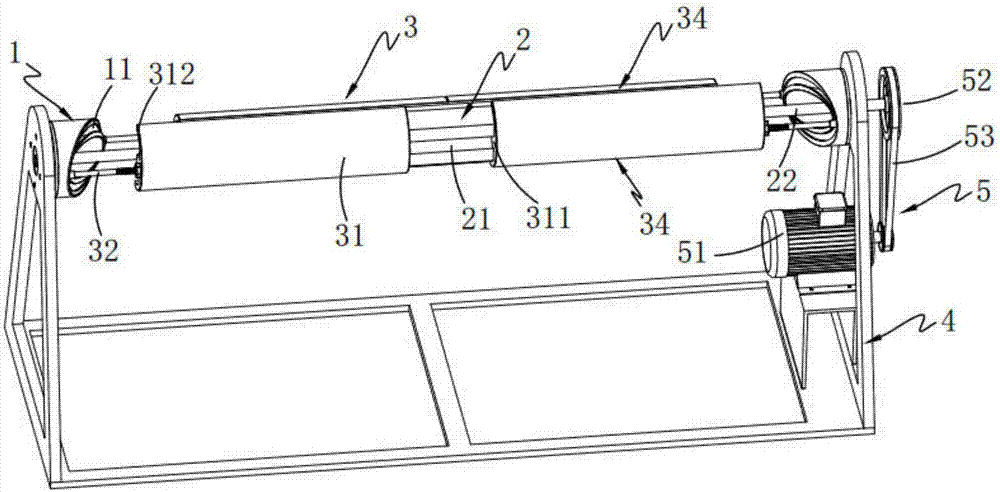

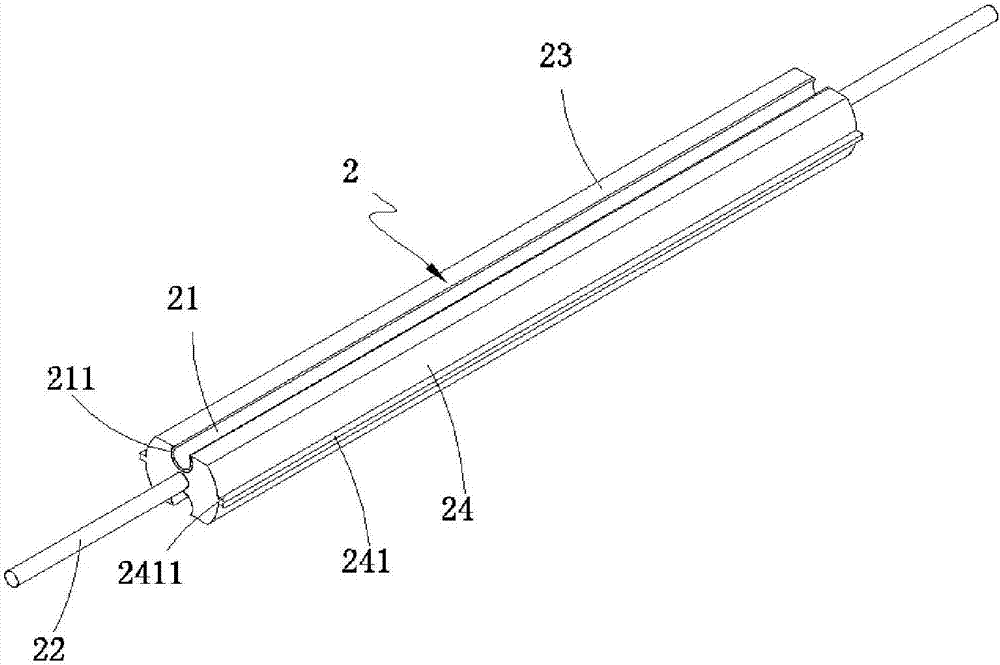

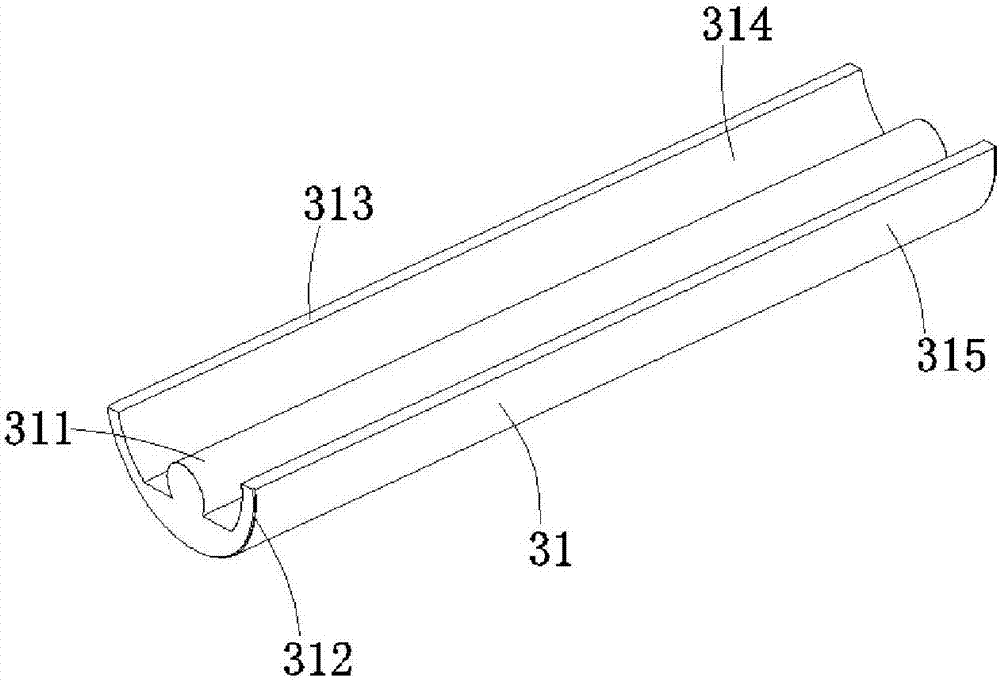

[0035] Such as figure 1 As shown, a film leveling guide roller mechanism includes a limit mechanism 1 horizontally symmetrically installed on both sides of the cloth roller frame 4, a guide roller 2, a leveling mechanism 3, a cloth roller frame 4 and a driving device 5, and the guide roller 2 The two ends of the two ends are respectively rotatably mounted on the corresponding limit mechanism 1, and one end passes through the corresponding limit mechanism 1 and is fixedly connected with the drive device 5; the leveling mechanism 3 includes rollers 2 along the guide rail A leveling assembly 33 arranged symmetrically in the radial direction, the leveling assembly 33 all includes a leveling unit 34 arranged symmetrically along the axial direction of the guide roller 2, the leveling unit 34 includes a leveling slider 31 and a push-pull mechanism 32, one end of the push-pull mechanism 32 is connected to the The leveling slider 31 is fixedly connected, and its other end is slidably c...

Embodiment 2

[0043] figure 1 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 It is a structural schematic diagram of a film leveling guide roller mechanism involved in the second embodiment; figure 1 As shown, the parts that are the same as or corresponding to those in Embodiment 1 use the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment two and embodiment one is:

[0044] Such as Figure 4 and Figure 5 As shown, the limiting mechanism 1 includes a semi-closed annular groove body 11, and the central axis of the limiting mechanism 1 is provided with a through hole 12;

[0045] Further, the inner surface of the semi-closed annular groove body 11 is an inclined surface, and an annular limiting guide rail groove 110 is provided on the inner surface, and the first limiting part 117 and the second limiting guide groove 110 are provided on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com