Gas solenoid rotor engine power device

A rotary engine and power plant technology, applied in the direction of engine components, machines/engines, combined engines, etc., can solve the problems of expensive construction, pressure difference, large fuel consumption, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Specific embodiments of the present invention will be further described below.

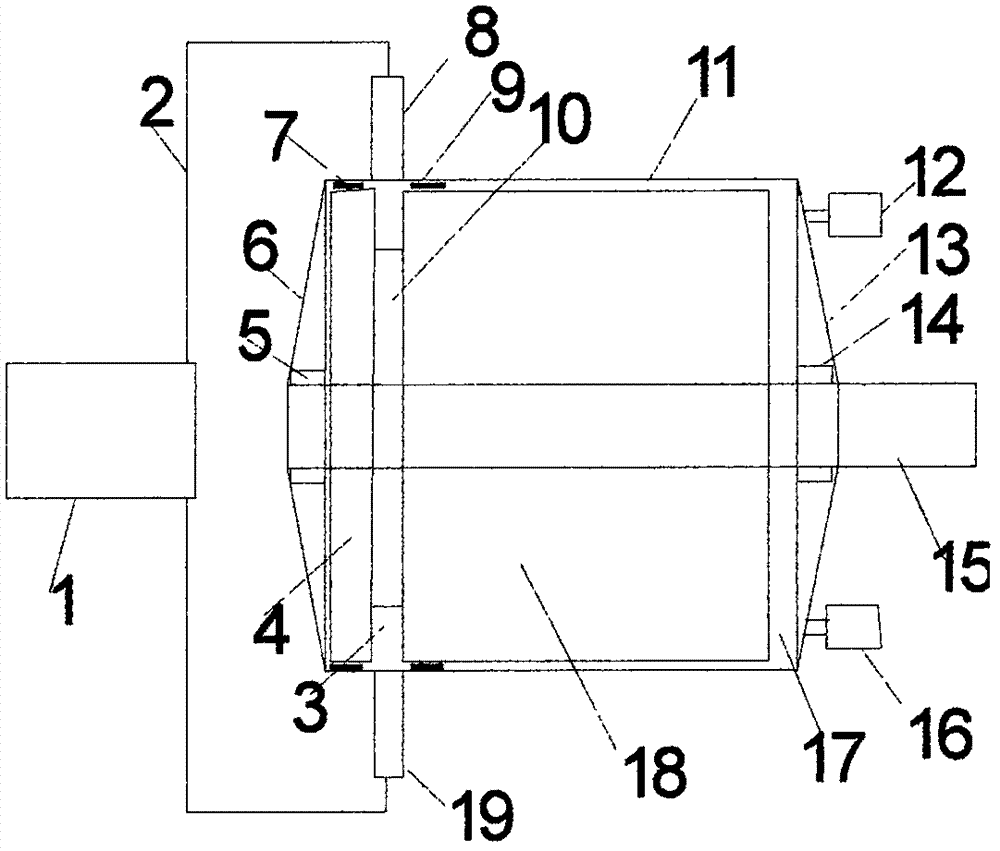

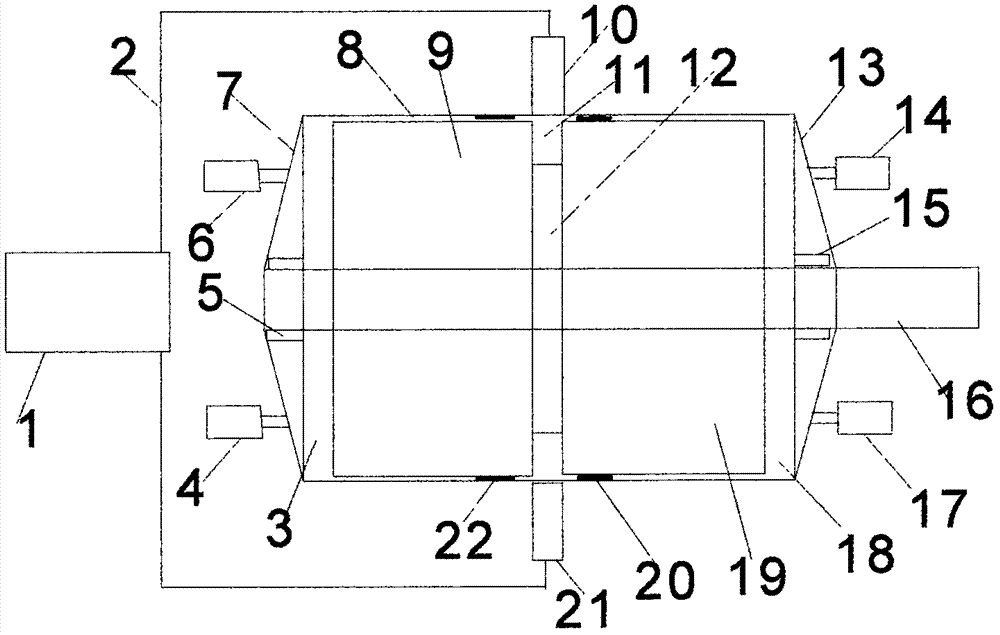

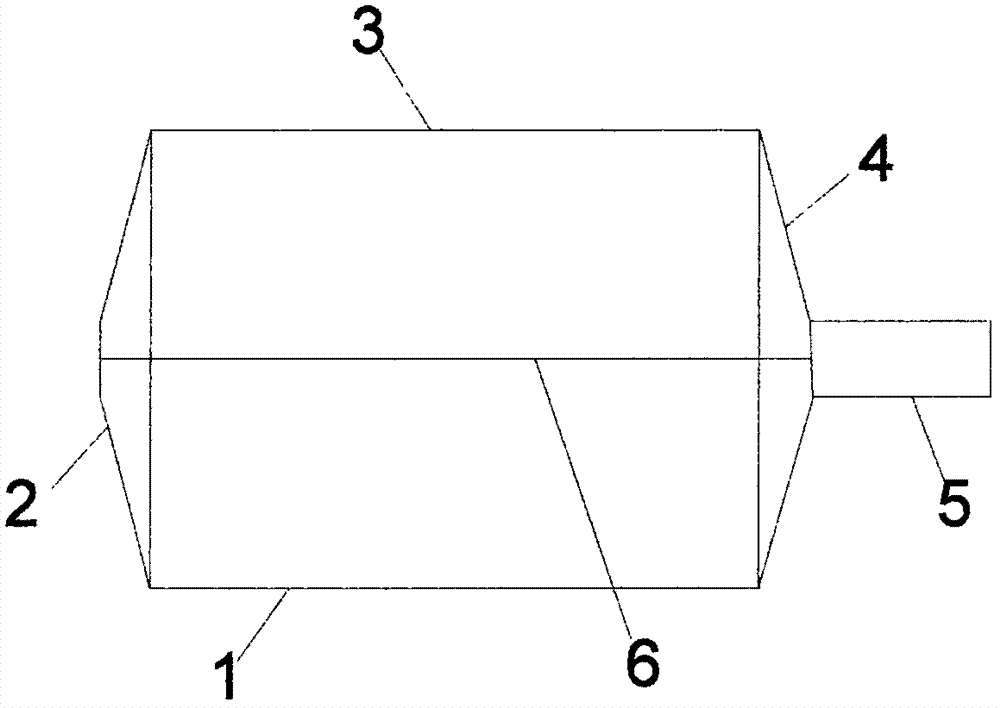

[0057] A gas helical rotor engine power device, including a gas turbine engine power device, is composed of a gas generator and a single or double-ended helical rotor engine. Make a head cylinder-neck cylinder-built-in coil cylinder on the body as a whole, or make a left built-in coil cylinder-neck cylinder-right built-in coil cylinder on the same cylinder As a whole, the cross-sectional area of the spiral tube from the air inlet to the exhaust port is gradually released; the gas generator is composed of an air compressor output pipe connected to the combustion chamber of the flame tube, and the exhaust port of the combustion chamber of the flame tube is connected to the combustion chamber. The annular combustor of the helical rotor engine is air-connected, the compressed air output by the air compressor unit is heated by the flame cylinder combustor, and high-temperature and high-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com