Optimization method for low-pressure axial fan impeller blade

A technology of impeller blades and optimization method, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, non-variable-capacity pumps, etc. , to achieve the effect of shortening design time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

[0026] The specific steps of the optimization method for the impeller blades of the low-pressure axial flow fan are as follows:

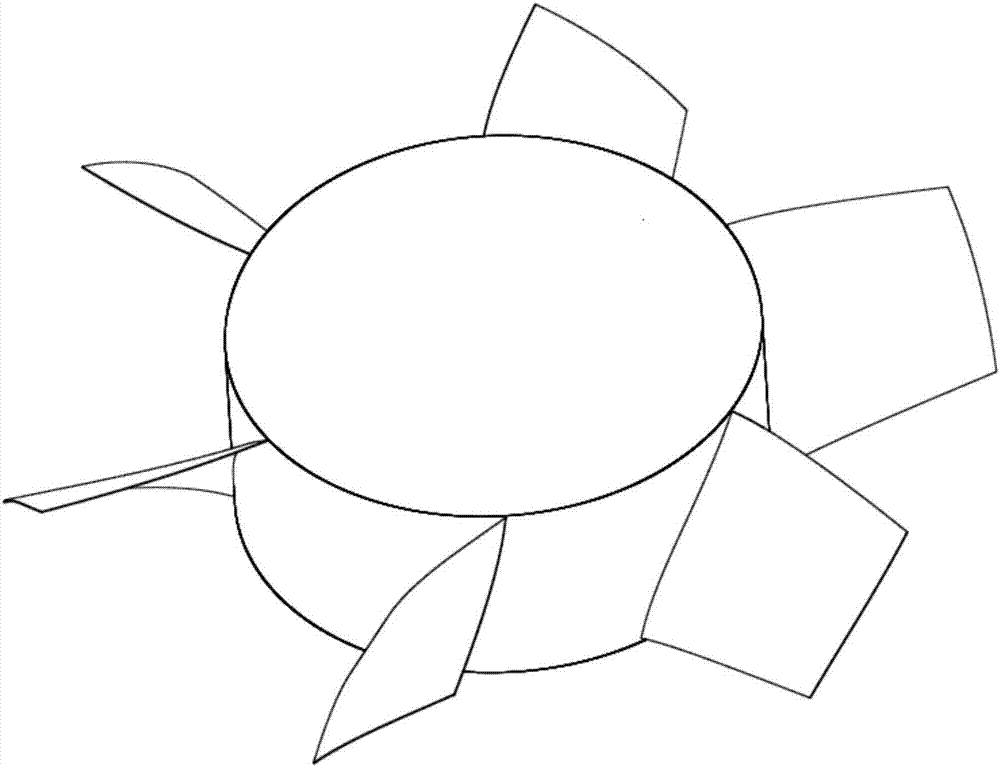

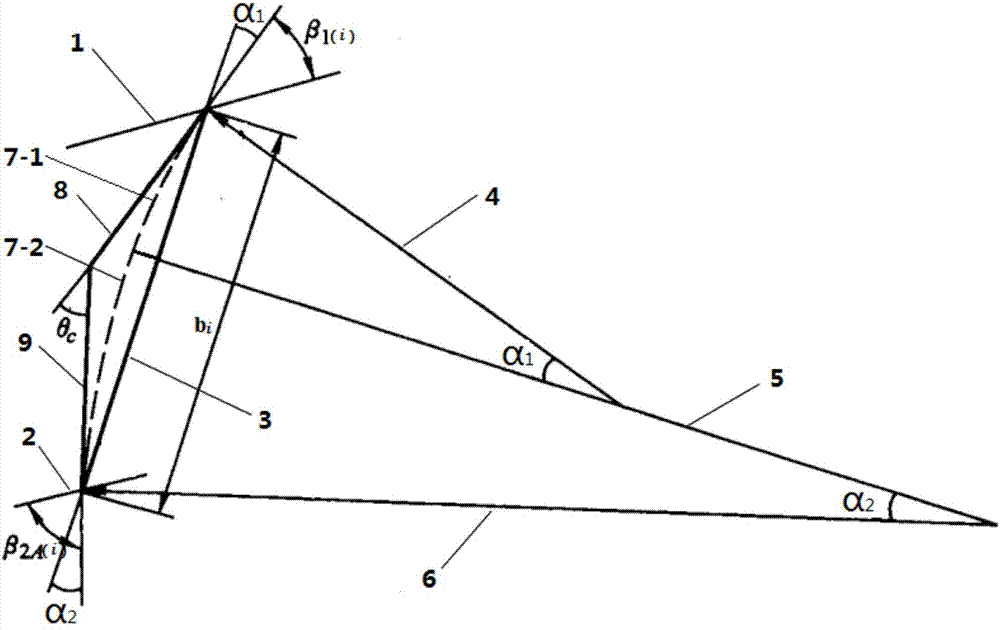

[0027] Step 1. Establish the impeller model to be optimized as figure 1 As shown, the impeller to be optimized is the impeller of the SDF-11.2 tunnel axial flow fan produced by Shaoxing Shangyu Jiuyang Fan Co., Ltd., and the distance between the hub side wall of the impeller and the outer end of the blade is 8s. On one blade of the model, eight sections vertical to the radial direction of the impeller and the corresponding molding lines of the eight sections are taken. The distance between adjacent sections is s, and the innermost section is tangent to the side wall of the hub. Measure the chord length b of the eight sections respectively i , i=1,2,3,...,8, and the exit geometric angle β 2A(i) , i=1,2,3,...,8. Remove all chamfers and rounded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com