Hydraulic cylinder durability test bed

A technology of durability test and hydraulic cylinder, which is applied in the field of hydraulic cylinder test, can solve problems such as unfavorable market requirements, lack of hydraulic cylinder test methods, and single hydraulic cylinder test means and methods, so as to facilitate widespread use and reduce production and processing costs , switching convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention will be further described below by means of drawings and specific embodiments.

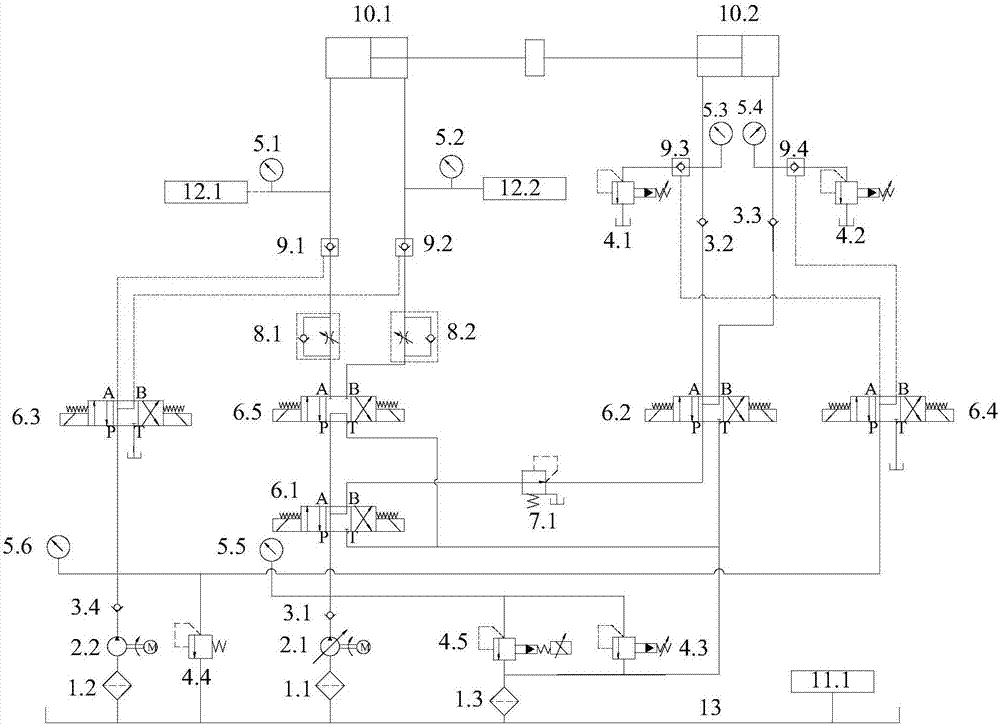

[0021] Hydraulic cylinder durability test bench, such as figure 1 As shown, it includes a first hydraulic cylinder 10.1, a second hydraulic cylinder 10.2, an oil tank 13 and a control circuit, and the piston rod of the first hydraulic cylinder 10.1 is connected to the piston rod of the second hydraulic cylinder 10.2 through a quick joint;

[0022] The rodless chamber of the first hydraulic cylinder 10.1 is connected to the working oil port A of the M-type electromagnetic reversing valve 6.5 through the first hydraulic control check valve 9.1 and the first one-way throttle valve 8.1 in sequence; the first hydraulic cylinder 10.1 has The rod cavity is connected to the working oil port B of the M-type electromagnetic reversing valve 6.5 through the second hydraulic control check valve 9.2 and the second one-way throttle valve 8.2 in sequence, and the pressure oil port P of the M-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com