Fully automatic oil fume detection equipment

A testing equipment, fully automatic technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of manual operation, poor timeliness, high cost of human resources, avoid damage to the health of workers, optimize the detection accuracy, and shorten the sampling period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

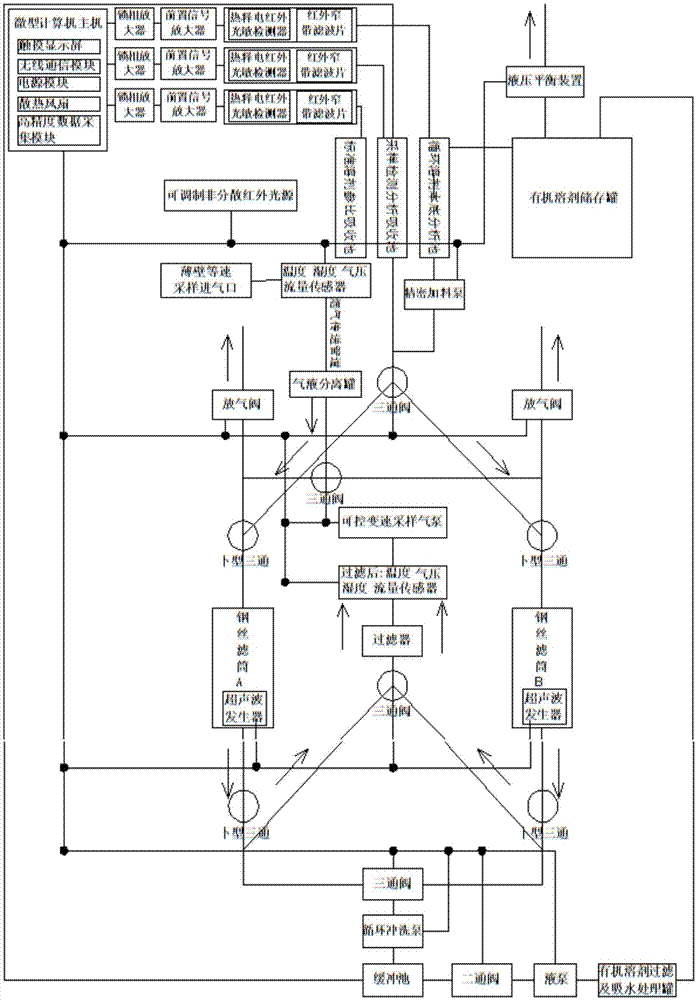

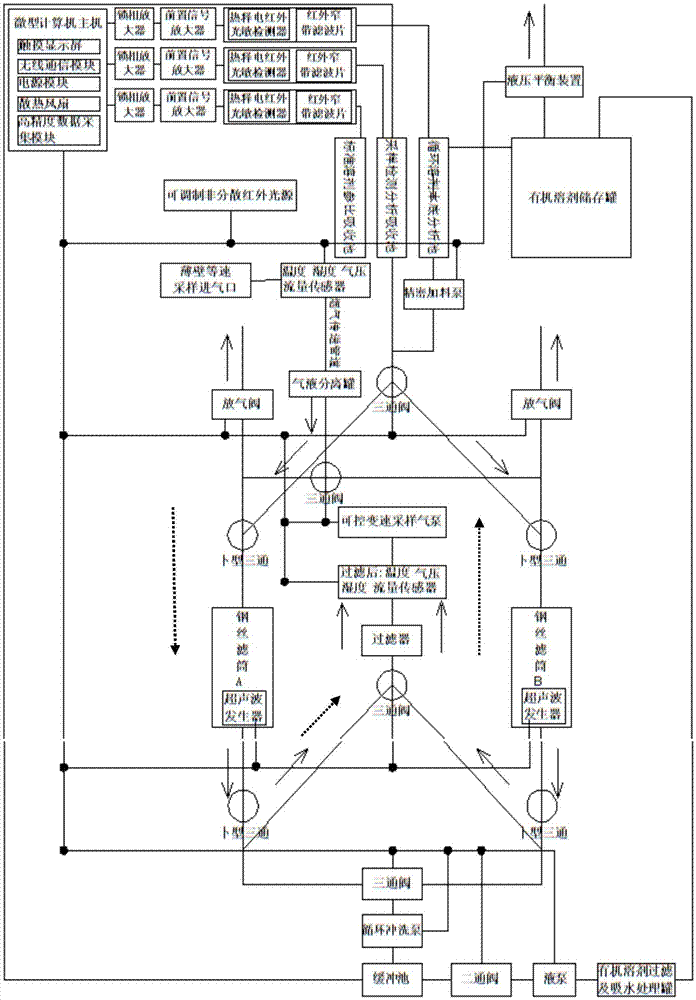

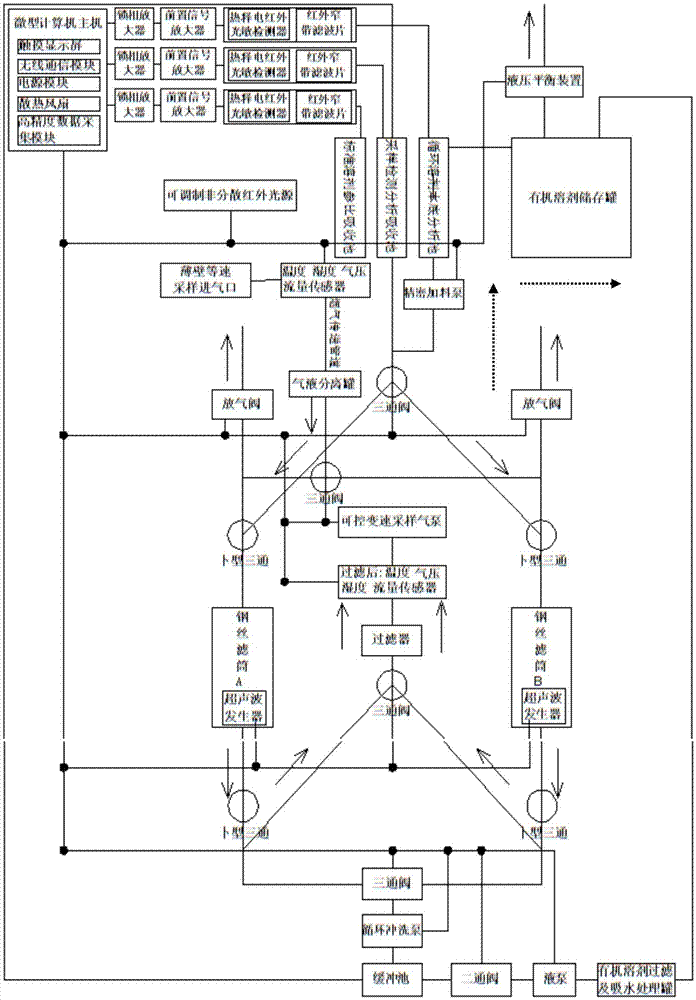

[0031] see Figure 1-Figure 8, the present invention provides a technical solution: a fully automatic oil fume detection device, including three parts: an isokinetic sampling gun, a flue gas conveying pipe, and a detection equipment body; After entering the detection equipment body, it is filtered through the steel wire filter cartridge and then discharged from the equipment. After the sampling period is over, the microcomputer host automatically controls the completion of solvent injection, ultrasonic cleaning of the steel wire filter cartridge, infrared spectroscopic absorption method detection, multi-parameter conversion correction and other procedures, and finally outputs oil fume concentration detection. result. A thin-wall constant velocity sampling inlet and flue gas physical parameter sensors such as flue gas velocity, flue temperature, flue gas humidity, and flue gas pressure are arranged at the head of the constant velocity sampling gun, and the flue gas transmission...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com