Bottleneck defect detection method based on gradient direction histograms

A gradient direction and defect detection technology, which is applied in the direction of optical defect/defect, image enhancement, image analysis, etc., can solve the problems of large amount of calculation, low efficiency, high false detection rate, etc., to improve detection accuracy and reduce operating overhead , to meet the real-time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

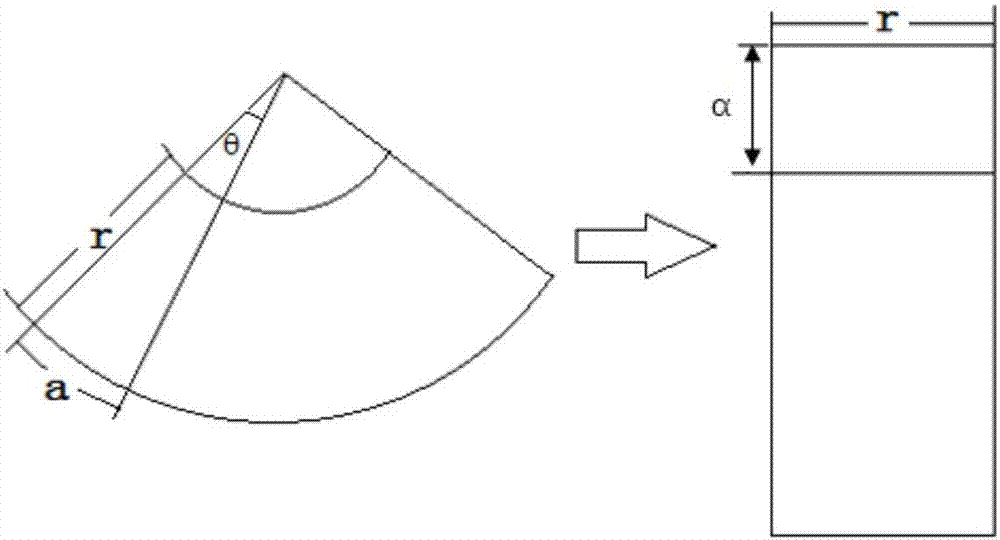

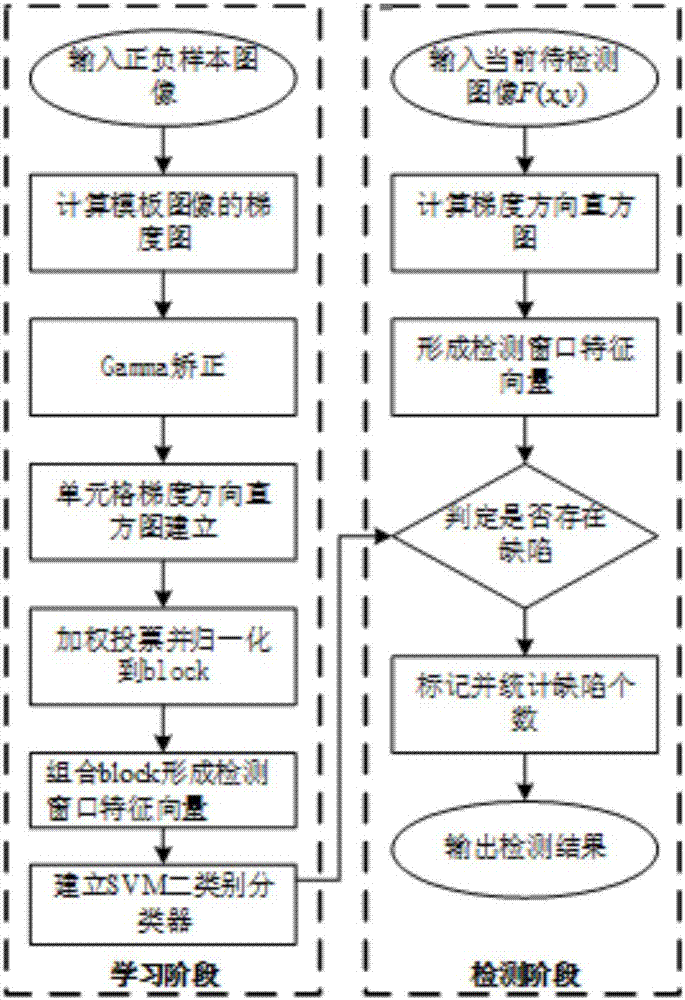

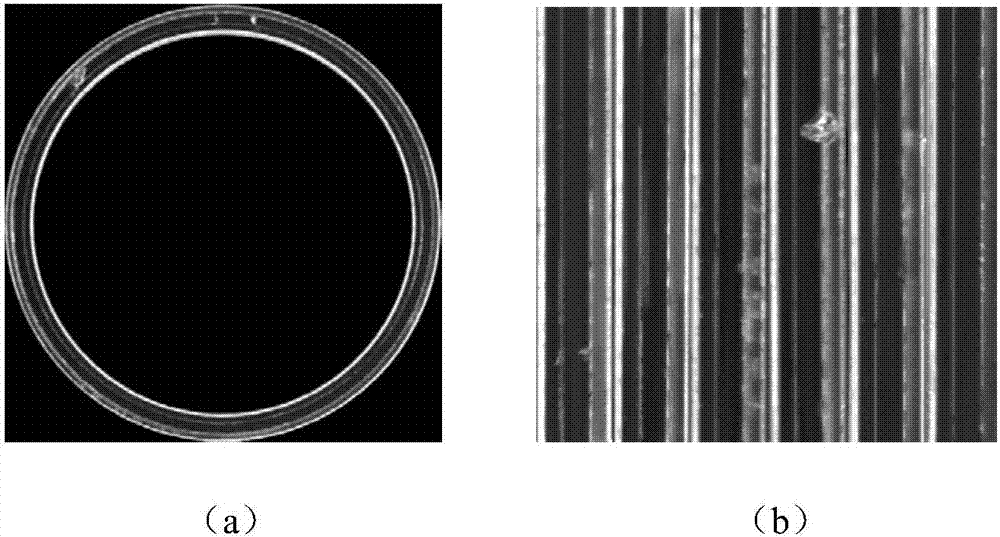

[0053] combine figure 2 , this embodiment first stretches the ring part of the bottle mouth into a rectangle, then cuts and stitches it to reduce the width and height difference of the rectangle, takes the corrected rectangle as a sample picture, and performs Gamma correction on the defective and non-defective sample pictures respectively , normalize the sample image, divide the sample image into multiple windows (for example, 32*32 pixels), count the histogram distribution of the gradient direction respectively, and obtain the feature vector, use the support vector machine to form a classifier, and use it for the defect of the subsequent bottle mouth image detection. Then, for the bottle mouth image to be detected, the feature vector of each detection window is obtained through the gradient direction histogram, and combined with the pre-formed classifier, it is determined whether the current window has defects, and the number of defects is counted and marked for the entire b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com