Generator preferably of wind turbine

A technology for wind turbines and generators, applied in wind engines, engines, wind power generation, etc., can solve problems such as increased power loss and increased heat production, and achieve the effects of reducing torque fluctuations, reducing hot spots, and high cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

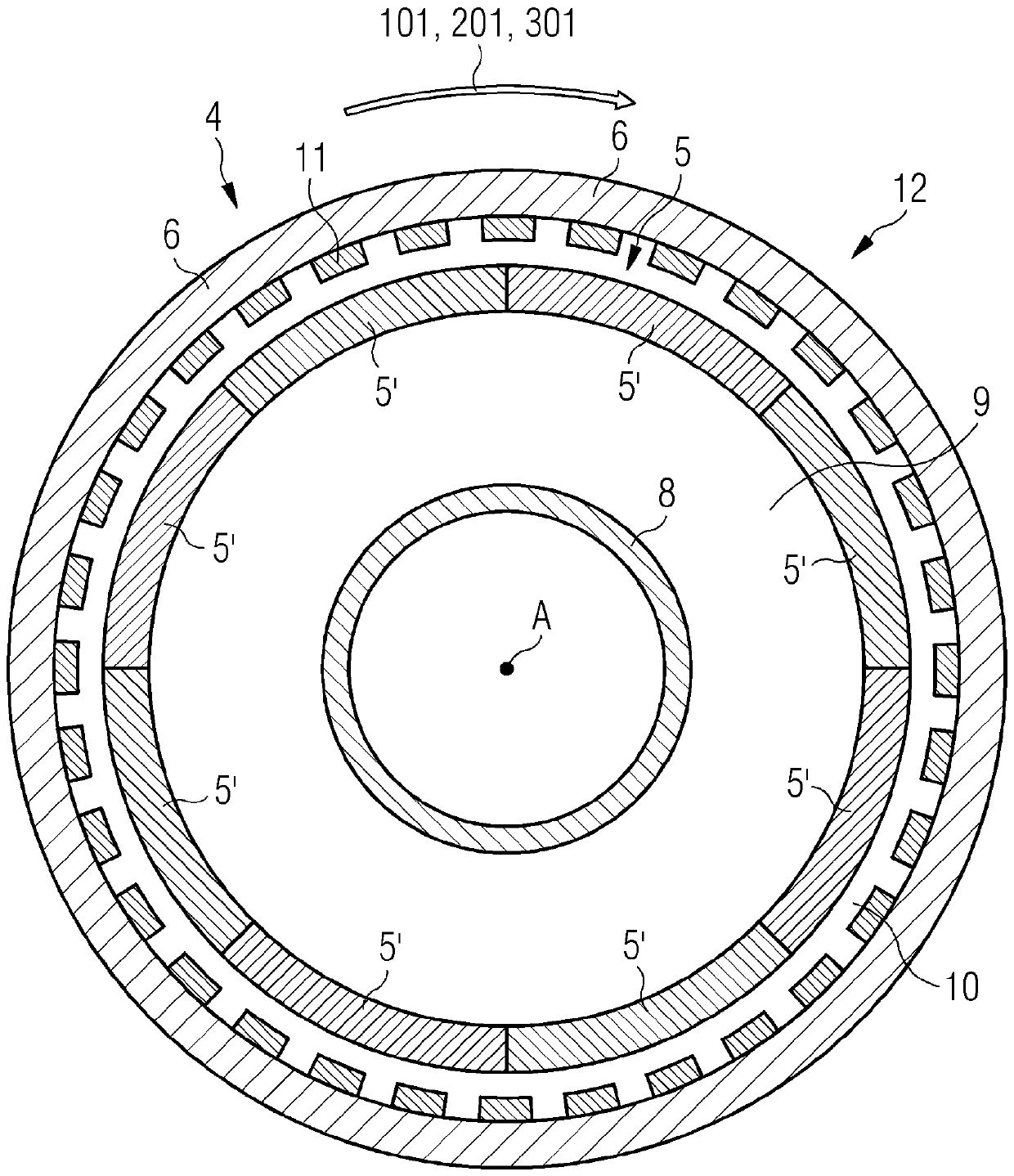

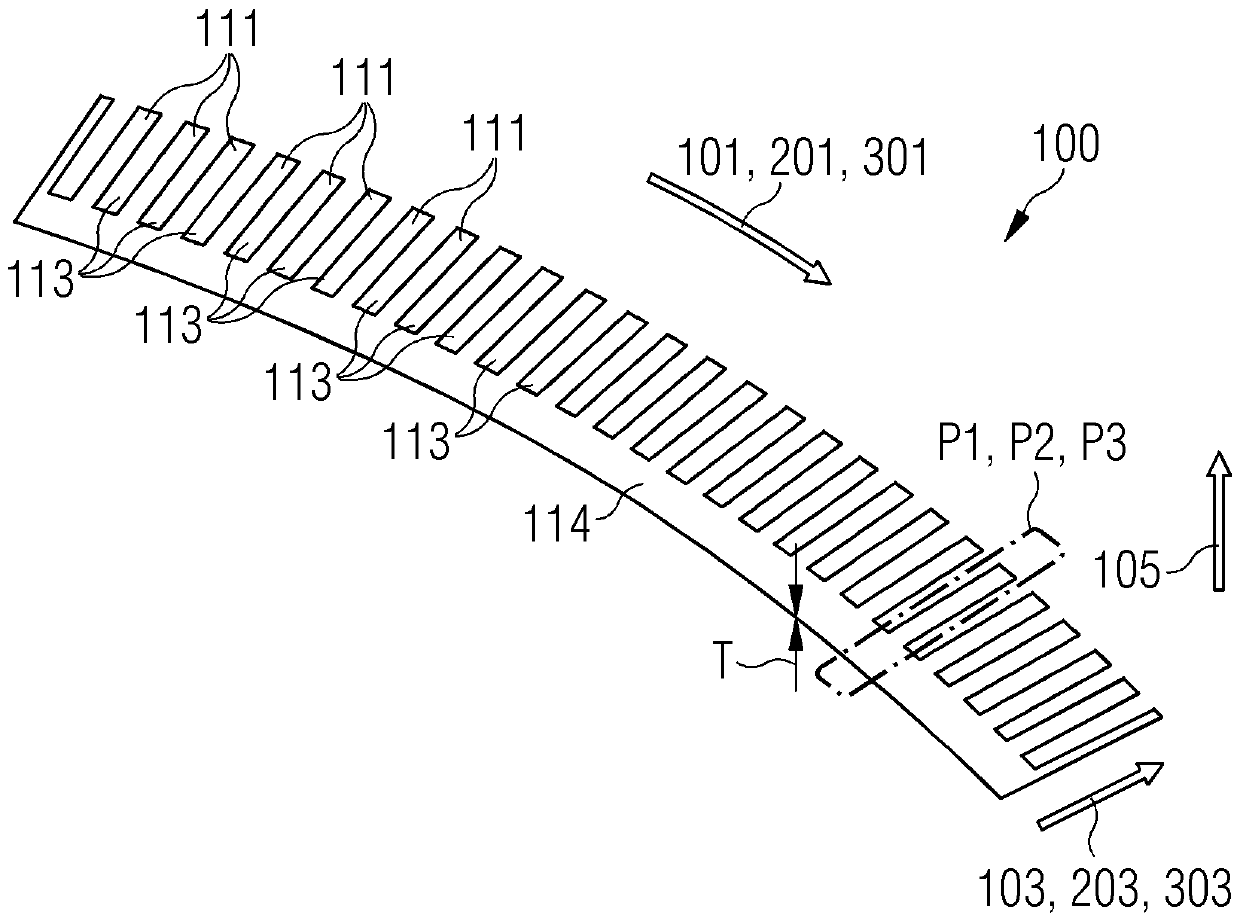

[0069] figure 1 A schematic partial sectional view of a wind turbine 1 is shown. The wind turbine 1 is a direct drive wind turbine intended for onshore or offshore applications and comprises a rotatable rotor hub 2 having a number of rotor blades 3 attached to the rotor hub 2 . The rotor hub 2 is adapted to transmit a rotational movement to a rotor 4 . The rotor 4 is rotatably supported with respect to the stator 5 , and includes permanent magnets 11 mounted on the inner surface of the rotor 4 and facing the stator 5 . Thus, the rotor 6 is supported on a corresponding bearing unit 7 arranged on a non-rotatable hollow shaft 8 , whereby the stator 5 is supported on a stator frame 9 . The stator frame 9 is supported directly on a central hollow shaft 8 which extends along a 90° rounded angle and is connected to a vertical wind turbine tower 20 .

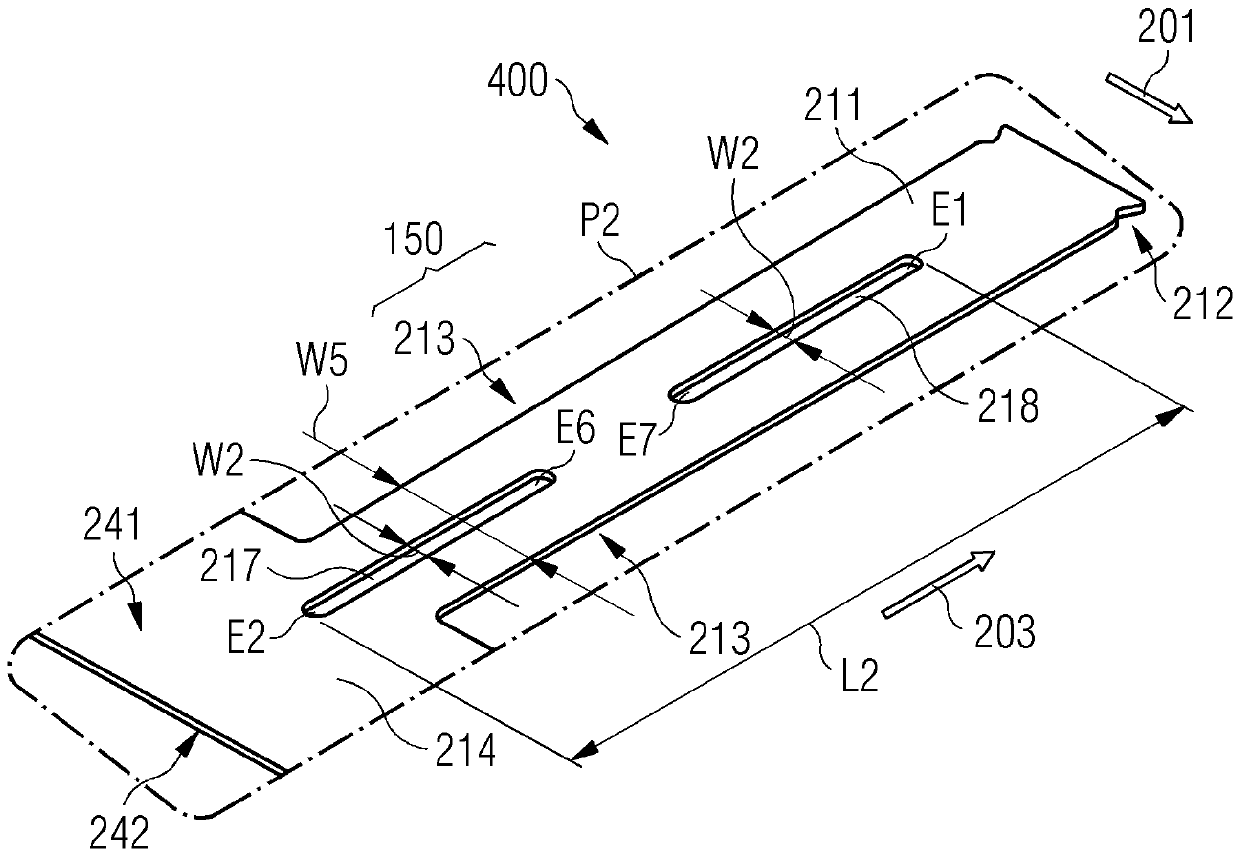

[0070] The air gap 10 extends in the axial direction 404 between the stator 5 and the permanent magnets of the rotor 4 . The radia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com