Multi-core pure electric module power plant

A technology of electric modules and power devices, applied in the direction of electric power devices, power devices, electromechanical devices, etc., can solve the problems of long power development cycle of new models, unsafe high voltage, and few gears of electric vehicles, etc., to achieve appearance and layout Flexibility, reduced development cycle and cost, and low sliding resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with embodiment.

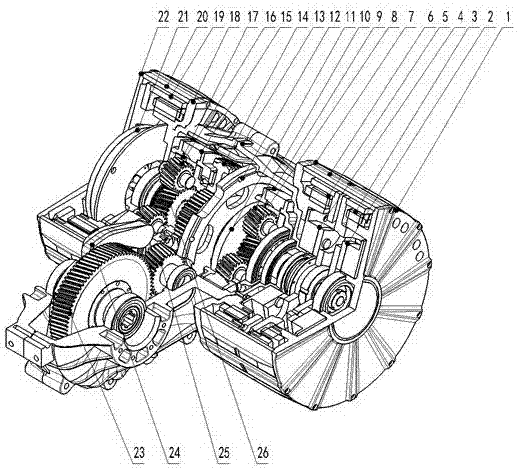

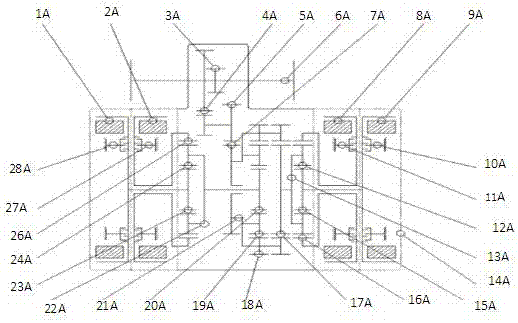

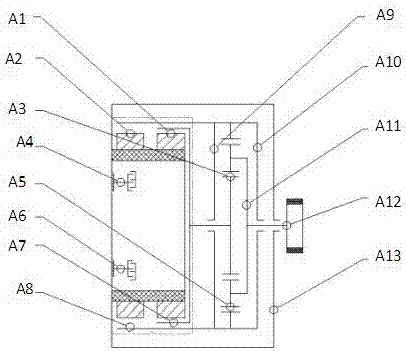

[0028] Multi-core pure electric module power plant, such as figure 1 Shown is a schematic diagram of the structure of the three-motor A model. figure 1 The outer rotor motor shown above is taken as an example to illustrate the structure, and the power input part can use other specification motors such as inner rotor as the power source. The multi-core pure electric module power unit includes A motor mount 1, A motor brake 2, A motor 3, B motor brake 4, B motor 5, right outer cover 6, B motor mount 7, sun gear 1 8, planetary gear 1 9 , Inner ring gear 1 10, planetary carrier 1 11, middle support plate 12, power casing 13, output gear 14, inner ring gear 2 15, planetary gear 2 16, planetary carrier 2 17, C motor mount 18, C motor 19 , Left housing 20, C motor brake 21, left end cover 22, differential 23, parking brake device 24 and speed change gear 25. Wherein, an intermediate supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com