Fabricated houses based on cold-formed thin-walled steel

A cold-formed thin-walled steel, prefabricated technology, applied in building components, buildings, building structures, etc., can solve the problems of house sound insulation, poor thermal insulation performance, unreasonable force points, large internal stress, etc., and achieve seismic performance. Superior, ensuring the sound insulation effect, the effect of alleviating the degree of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

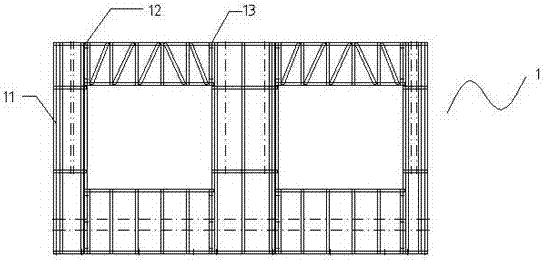

[0035] Such as Figure 1 to Figure 8 The shown prefabricated house based on cold-formed thin-walled steel includes a house frame 1 , a floor structure 2 and a wall structure 3 .

[0036] The house frame 1 includes a wall corner steel structure 11 , a truss beam and an outer wall assembly structure 12 and a truss beam and an inner wall assembly structure 13 .

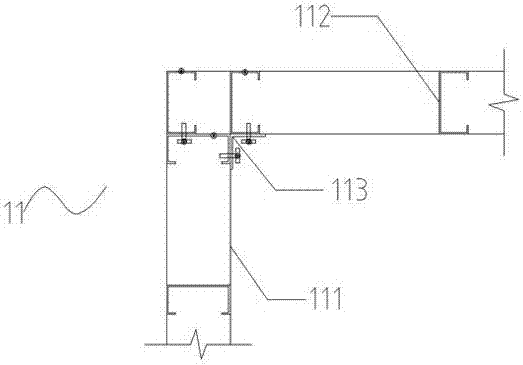

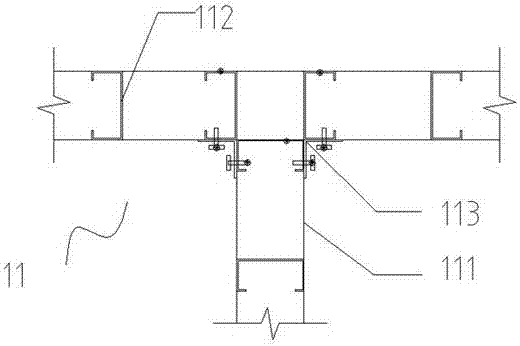

[0037] The wall corner steel structure 11 includes a wall frame structure 111, a column 112 and an angle steel A113; the pair of wall frame structures 111 whose ends are perpendicular to each other and the column 112 and angle steel A113 vertically embedded in the wall frame structure 111 form L-shaped corner node structure; or the wall frame structure 111 with the three ends connected to each other and the column 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com