Steel wire bundle anchor rod and construction method thereof for reinforcing weak surrounding rock

A technology of weak surrounding rock and steel wire bundles, which is applied in the installation of bolts, earthwork drilling, infrastructure engineering, etc., can solve the problems of insufficient resistance, high installation and use costs, complex structure, etc., to enhance the anchoring force, increase the The effect of the action area and the increase of the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to facilitate the understanding of the technical means, creative features and goals achieved by the present invention, the present invention is further described below in conjunction with the schematic diagrams, but the scope of protection claimed by the present invention is not limited to the scope described in the specific implementation.

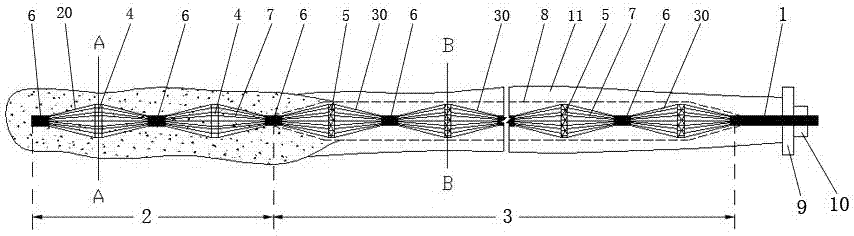

[0031] A steel wire anchor for reinforcing weak surrounding rocks, the anchor comprises an anchor head 1 and a rod body, the rod body is coated with lubricating grease, the front end of the rod body extends into a borehole 11 in the surrounding rock, the tail end of the rod body is connected to the Anchor head 1 connection, such as figure 1 As shown, the rod body is composed of an anchor section 2 and a free section 3, and the free section 2 is provided with a PVC sleeve 8.

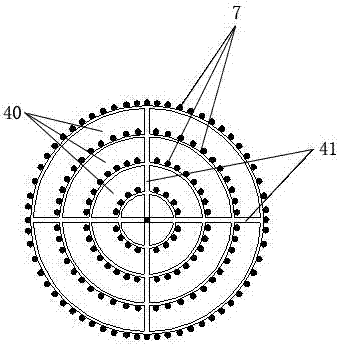

[0032] Such as figure 1 As shown, the anchoring section 2 includes several successively connected anchoring sections 20, and each anchoring section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com