A highly integrated integrated wind power pitch controller

An integrated, controller technology, applied in the control of wind turbines, single motor speed/torque control, wind power generation, etc., can solve the problems of cumbersome production process, easy aging of cable connectors, complex layout and wiring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below by means of the accompanying drawings.

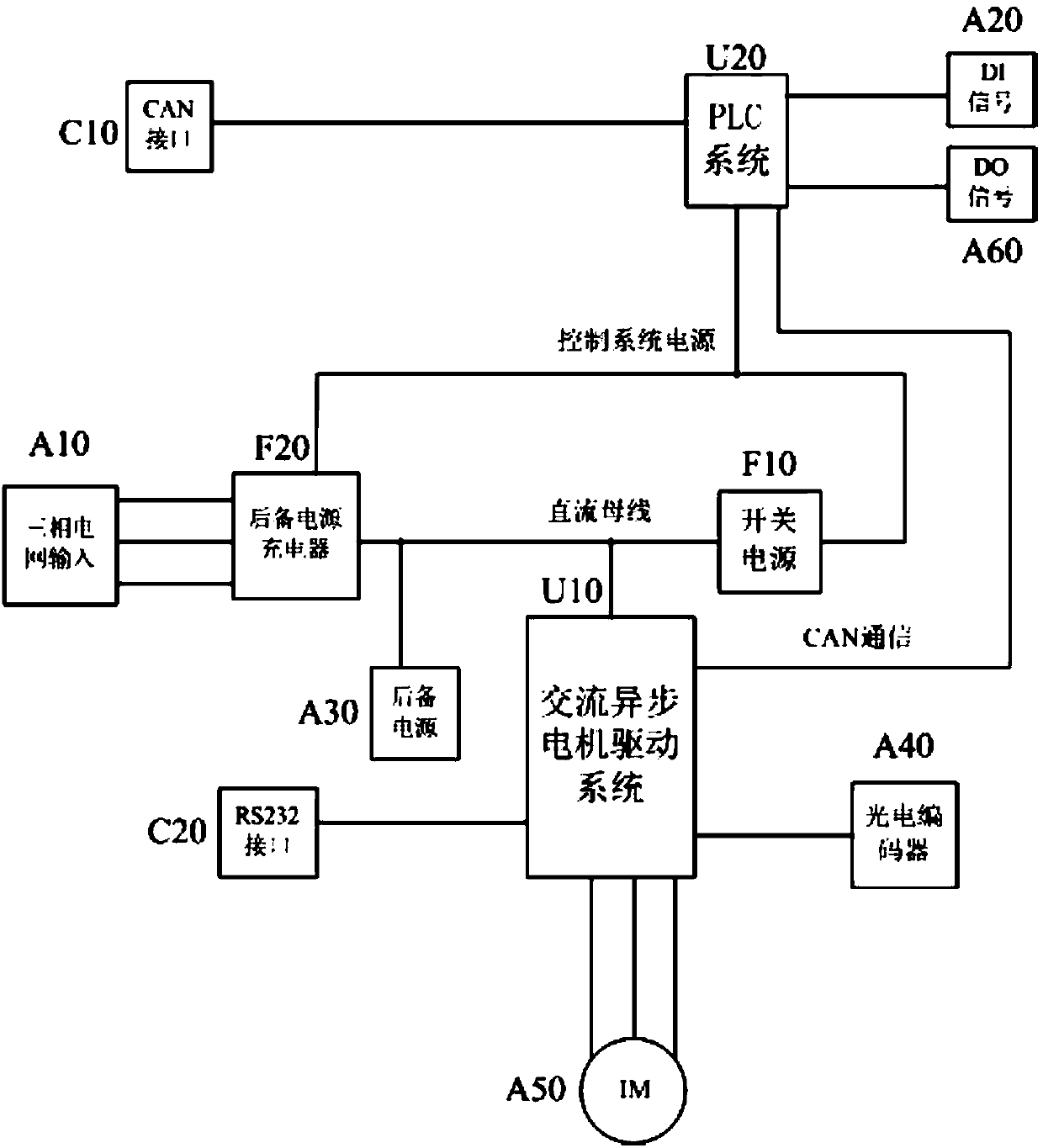

[0033] Such as figure 1 Shown is the general schematic diagram of the traditional pitch system, including AC asynchronous motor drive system U10, switching power supply F10, backup power charger F20, PLC system U20 and other four discrete components. The external three-phase grid input A10 is connected to the backup power charger F20, the output of the backup power charger F20 is connected to the backup power A30, and the backup power A30 is connected to the system DC bus at the same time. The DC bus is connected to the input of the switching power supply F10, and the output of the switching power supply F10 is connected. figure 1 As shown in the traditional pitch system, the DC bus of the system is not enclosed in the cabinet, and it is coupled with the AC asynchronous motor drive system U10, the switching power supply F10, the backup power charger F20 and the back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com