Automatic slurry filter device

A filter device and slurry technology, applied in the direction of filtration separation, membrane filter, fixed filter element filter, etc., can solve the problems of reducing the service life of the screen plate, volatile organic components, expensive slurry, etc., to save production The effect of time and labor, simple and convenient operation, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

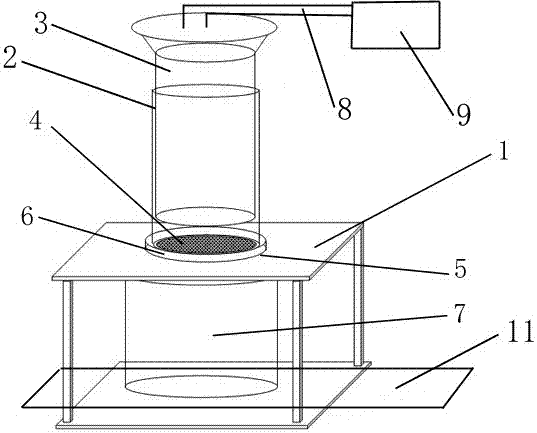

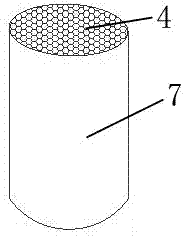

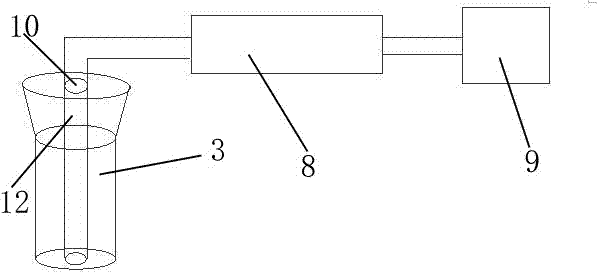

[0015] Such as Figure 1-3 As shown, an automatic slurry filtering device according to the present invention includes a material receiving bracket 1 and an extruder, and the extruder includes a hollow cylinder 2 and an extrusion piston 3 installed in the cylinder , the bottom of the cylinder is hollowed out with a filter 4; the center of the extruding piston has a slurry pipeline 10 that goes straight to the bottom, and a push rod 12 that is matched with the pipeline is arranged in the pipeline, and the push rod is connected Telescopic rod, 8 telescopic rods are connected with motor 9, and the telescopic rod is driven by the motor to drive the push rod; hole, and fixed by the clamp 6; the bottom of the material receiving bracket is extended to both ends with a conveyor belt 11, the middle of the material receiving bracket is a hollow structure, and the upper part of the material receiving bracket is hollowed out at the bottom of the cylinder body. A material receiving box 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com