Ore-bearing hydrogen-rich water production method and device

A technology of production device and production method, which is applied in the field of production method and device of mineral-containing hydrogen-rich water, can solve the problems of consumption restriction of consumers, imbalance of human body electrolytes, high cost, etc., and solve the problem of insufficient consumption of consumers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

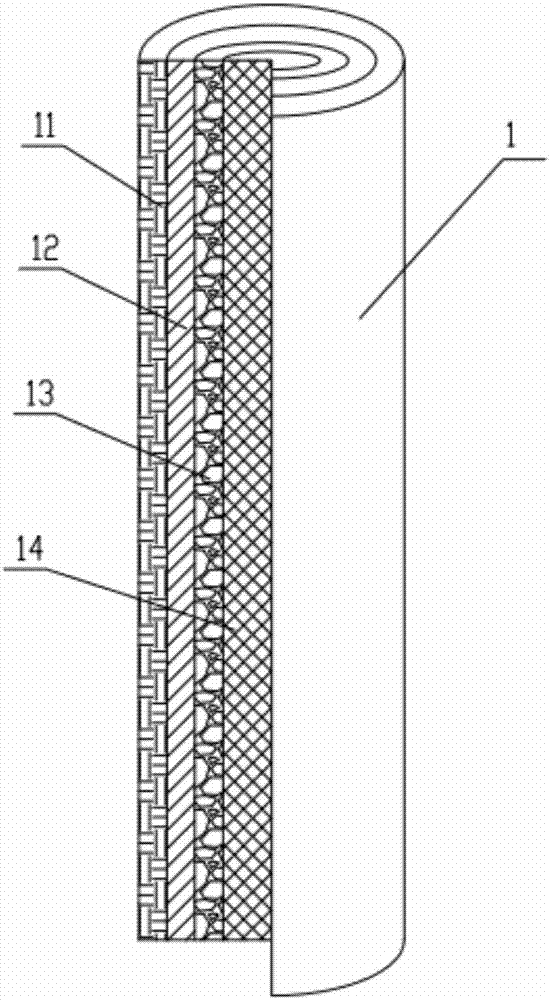

Embodiment 1

[0081] The functional granules are calculated in parts by weight, including 20% of negative potential balls, 60% of hydrogen balls, 10% of medical stone ceramic balls, and 10% of silver-loaded antibacterial balls. The total weight is 30g, including 6g of negative potential balls, 18g of hydrogen balls, 3g of medical stone ceramic balls, and 3g of silver-loaded antibacterial balls.

[0082] The mixed functional granules of the above examples with a total weight of 30 g were soaked in 300 ml of pure water (total soluble solids TDS<5) in an airtight container, soaked for 30 minutes, and then poured into a beaker for testing. The test results show that the total dissolved solids TDS: 112, the water-soluble hydrogen content: 407, and the oxidation-reduction potential mv: -116.

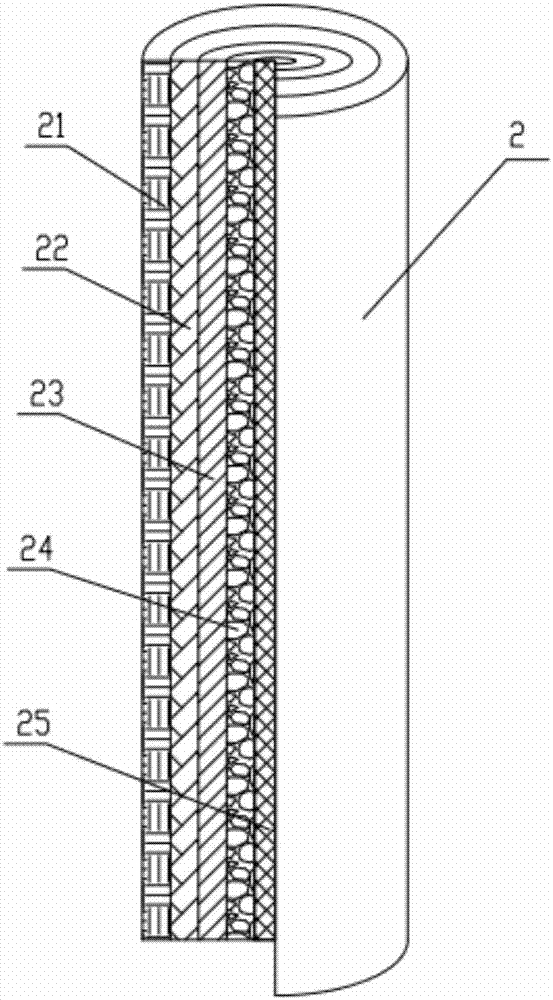

Embodiment 2

[0084] The functional particles include 50% of negative potential balls, 30% of hydrogen balls, 3% of medical stone ceramic balls, 10% of negative ion ceramic balls, and 7% of nano mineral crystals in parts by weight. The total weight is 30g, including 15g of negative potential balls, 9g of hydrogen balls, 0.9g of medical stone ceramic balls, 3g of negative ion ceramic balls, and 2.1g of nano mineral crystals.

[0085] The mixed functional granules of the above examples with a total weight of 30 g were soaked in 300 ml of pure water (total soluble solids TDS<5) in an airtight container, soaked for 30 minutes, and then poured into a beaker for testing. The test results show that the total dissolved solids TDS: 87, the water-soluble hydrogen content: 443, and the oxidation-reduction potential mv: -132.

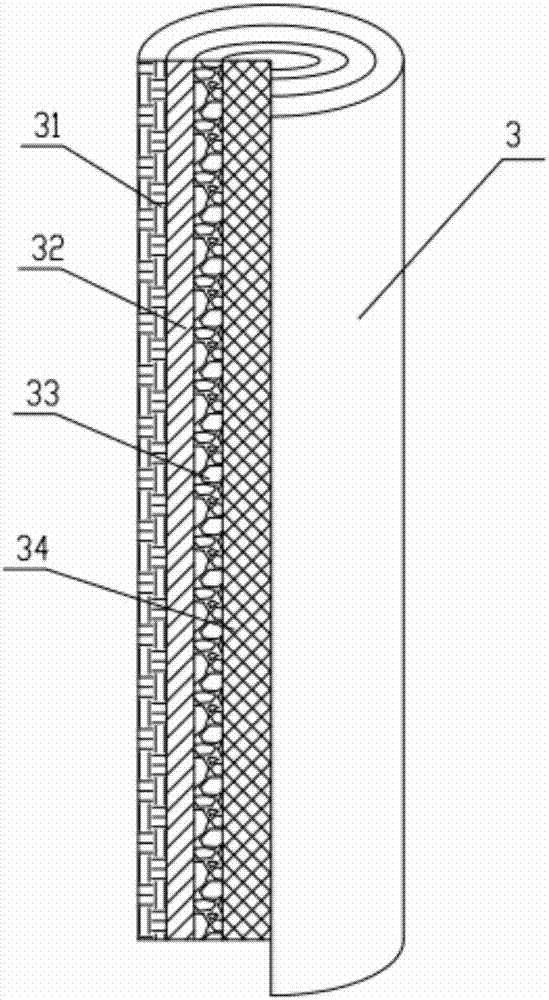

Embodiment 3

[0087] The functional particles are calculated in parts by weight, 80% of negative potential balls and 20% of medical stone ceramic balls. The total weight is 30g, including 24g of negative potential balls and 6g of medical stone ceramic balls.

[0088] The mixed functional granules of the above examples with a total weight of 30 g were soaked in 300 ml of pure water (total soluble solids TDS<5) in an airtight container, soaked for 30 minutes, and then poured into a beaker for testing. The test results show that the total dissolved solids TDS: 12, the water-soluble hydrogen content: 456, and the oxidation-reduction potential mv: -138.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com