N-butanol separation and purification device and method for separation and purification by adopting same

A technology of n-butanol and polymethoxydibutyl ether, applied in the field of chemical rectification, can solve the problems of difficult separation of n-butanol mixed solution, low separation purity of n-butanol, etc. Environmental protection pressure, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

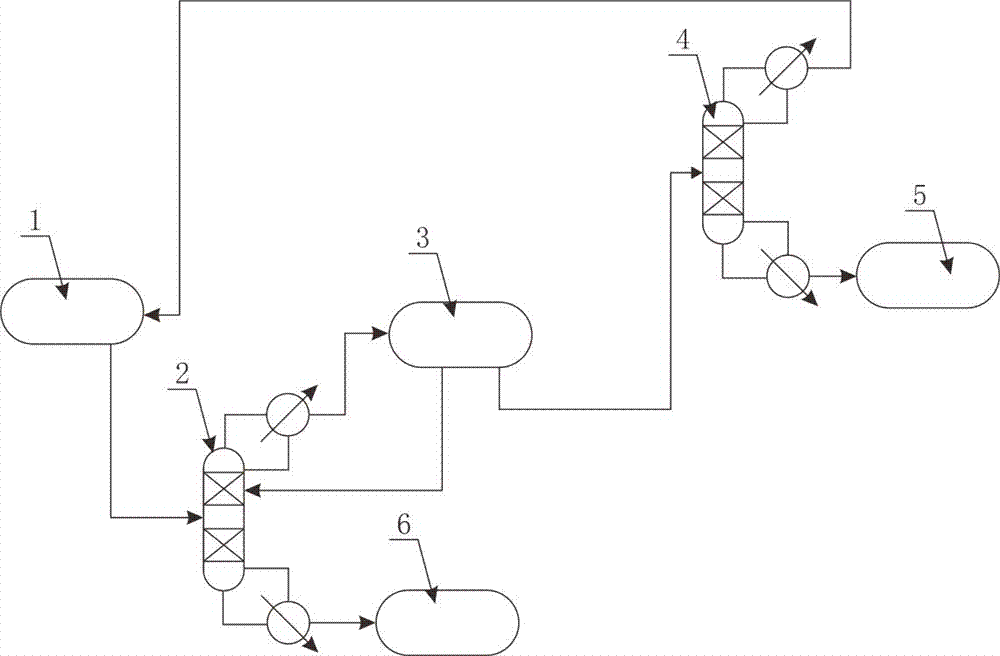

[0021] Such as figure 1 As shown, the n-butanol separation and purification device includes a first-stage chromatograph 1, a dehydration tower 2, a second-stage chromatograph 3, a rectification tower 4, and a n-butanol storage tank 5 connected in sequence.

[0022] Such as figure 1 As shown, both the primary chromatograph 1 and the secondary chromatograph 3 are provided with overflow plates, and the overflow plate separates the primary chromatograph 1 and the secondary chromatograph 3 into a light phase area and a heavy phase. Area; and in the light phase area, the heavy phase area and the rectification tower 4 are provided with level controllers for measuring the discharge of the separation liquid in the light phase area and the heavy phase area; the separation liquid is in the first chromatograph 1 And the secondary chromatograph 3 is left standing and separated.

[0023] Such as figure 1 As shown, the heavy phase zone of the primary chromatograph 1 and the heavy phase zone of...

Embodiment 2

[0031] The method for separating and purifying n-butanol using the above device includes the following steps:

[0032] (1) Add a mixture of 7% n-butanol, 80% water and 13% formaldehyde to the primary chromatograph and let it stand at 80°C for 0.5h. The components in the light phase of the primary chromatograph are used as The raw materials return to the synthesis system; the components in the heavy phase zone enter the dehydration tower and continue to separate;

[0033] (2) Separate under the condition that the temperature of the top of the dehydration tower is 100℃, the temperature of the bottom of the dehydration tower is 100℃, the reflux ratio is 2, and the pressure is 0.2mPa. The content is controlled at about 100ppm, and the formaldehyde component is stored in the formaldehyde storage tank; the mixed component of n-butanol, water and formaldehyde is obtained from the top of the dehydration tower, and then it enters the secondary chromatograph to continue the separation;

[003...

Embodiment 3

[0036] The method for separating and purifying n-butanol using the above device includes the following steps:

[0037] (1) Add a mixture of 10% n-butanol, 82% water and 8% formaldehyde to the primary chromatograph, stand at 80°C for 0.5h, and use the components in the light phase of the primary chromatograph as The raw materials return to the synthesis system; the components in the heavy phase zone enter the dehydration tower and continue to separate;

[0038] (2) Separate under the conditions that the temperature of the top of the dehydration tower is 85℃, the temperature of the bottom of the dehydration tower is 110℃, the reflux ratio is 2, and the pressure is 0.2mPa, and the formaldehyde component is obtained from the bottom of the dehydration tower. The content is controlled at about 100ppm, and the formaldehyde component is stored in the formaldehyde storage tank; the mixed component of n-butanol, water and formaldehyde is obtained from the top of the dehydration tower, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com