Energy-efficient hard carbon black reaction furnace

A hard carbon black, high-efficiency and energy-saving technology, applied in sustainable manufacturing/processing, burner, chemical industry, etc., to achieve the effect of improving cracking rate, improving fuel efficiency, and preventing coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

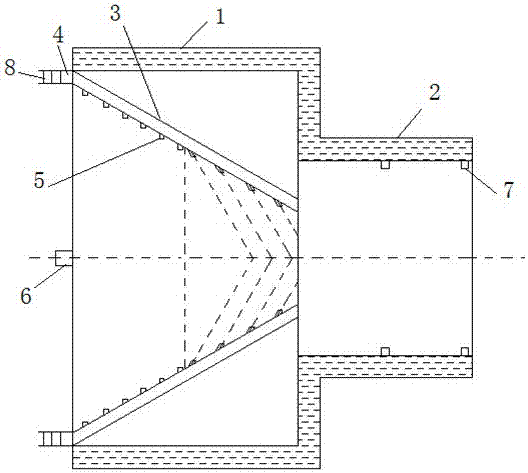

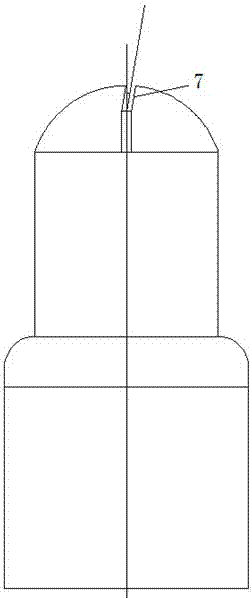

[0012] Such as figure 1 , figure 2 As shown, the present invention is achieved in this way, including a combustion chamber 1 and a throat section 2, the straight pipe section of the combustion chamber 1 is coaxially provided with a conical air acceleration guide tube 3, and the small opening of the conical air acceleration guide tube 3 On one side of the throat section 2, eight air inlets 4 are evenly arranged on the side wall of the large mouth of the conical air acceleration guide tube 3, and several air outlets 5 are evenly provided on the inner wall surface of the conical air acceleration guide tube 3, so that The central axis of the straight pipe section of the combustion chamber 1 is provided with a fuel inlet 6, and the middle section and the end positions of the throat section 2 are correspondingly staggered to set 4 feed oil nozzles 7 and 6 feed oil nozzles 7, and the feed oil nozzles in the middle section and the end positions Deviated from the radial axis by 10 de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com