A coupling method for separation, purification and immobilization of penicillin acylase for preparing 6-aminopenicillanic acid

A technology of penicillin acylase and aminopenicillanic acid, applied in the field of bioengineering, can solve the problems of insignificant impurity removal effect, cumbersome process steps, and low production efficiency, achieve small amplification effect, shorten operation time, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0067] (1) Fermentation culture of penicillin acylase

[0068] Using recombinantly expressed Pichia strains, adopt the method described in the existing literature (Luo Qian, high-density fermentation and immobilization of PGA produced by recombinant Pichia [D], master's degree thesis of Central South University of Forestry and Technology, 2013) Fermentation culture, test the enzyme activity of penicillin acylase in the obtained fermentation liquid is 83.2IU / mL.

[0069] (2) Fermentation broth pretreatment:

[0070] (i) After the fermentation is finished, add 0.01g / mL of ammonium sulfate according to the volume of the feed liquid, stir to dissolve, then add 0.008g / mL of cetyltrimethylammonium bromide according to the volume of the feed liquid, and stir for 25min; The temperature of the solution was raised to 45°C, and the pH was adjusted to 7.6 with 2mol / L NaOH solution at the same time; after the temperature and pH were adjusted in place, the temperature was maintained at 45°...

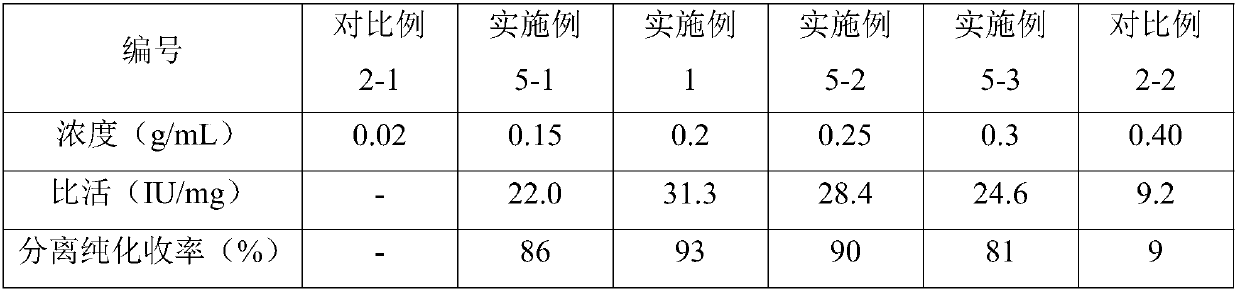

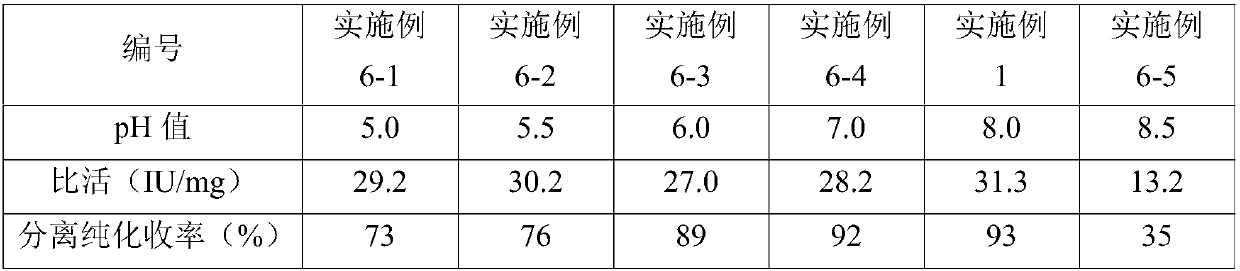

Embodiment 1

[0075] (1) Under the condition of 14°C, the phosphate (by K 2 HPO 4 .3H 2 O and KH 2 PO 4 Composition) be dissolved in the crude enzyme solution II of penicillin acylase that preparation example obtains in 90min and the pH value of adjusting solution in the process of adding is 8.0 (add KH first 2 PO 4 Adjust pH to 6.5, add K 2 HPO 4 .3H 2 O to adjust the pH to 8.3, and finally add KH 2 PO 4 Regulate pH to 8.0), obtain inorganic salt mixed solution;

[0076] (2) Mix the inorganic salt mixed solution obtained in step (1) with the mixed solution of tert-butanol and water recovered in step (3) according to the volume ratio of 1:0.6, vortex for 2 minutes until fully mixed, and then centrifuge at 3500g for 10 minutes, Form a three-phase distribution system consisting of an upper phase solution rich in tert-butanol, a middle phase solid, and a lower phase solution rich in salt and penicillin acylase, and separate the three-phase solution;

[0077] (3) get the upper phase ...

Embodiment 2

[0082] (1) Under the condition of 12°C, the phosphate (by K 2 HPO 4 .3H 2 O and KH 2 PO 4 Composition) is dissolved in the penicillin acylase crude enzyme liquid I that preparation example obtains and the pH value of adjusting solution in the process of adding is 6 (add KH first 2 PO 4 Adjust pH to 5, add K 2 HPO 4 .3H 2 O to adjust the pH to 7 and finally add KH 2 PO 4 Adjust the pH to 6), stir while adding salt (stirring speed is 250rpm) to fully dissolve the salt, and obtain a mixed solution of inorganic salt;

[0083] (2) Mix the inorganic salt mixed solution obtained in step (1) with the mixed solution of tert-butanol and water recovered in step (3) according to the volume ratio of 1:0.25, vortex for 2 minutes until fully mixed, and then centrifuge at 2000g for 20 minutes, Form a three-phase distribution system consisting of an upper phase solution rich in tert-butanol, a middle phase solid, and a lower phase solution rich in salt and penicillin acylase, and sep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap