A kind of method for preparing iridium single crystal

A single crystal, electron gun technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of no iridium single crystal growth method, difficult to control the length of the melting zone, and high iridium density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

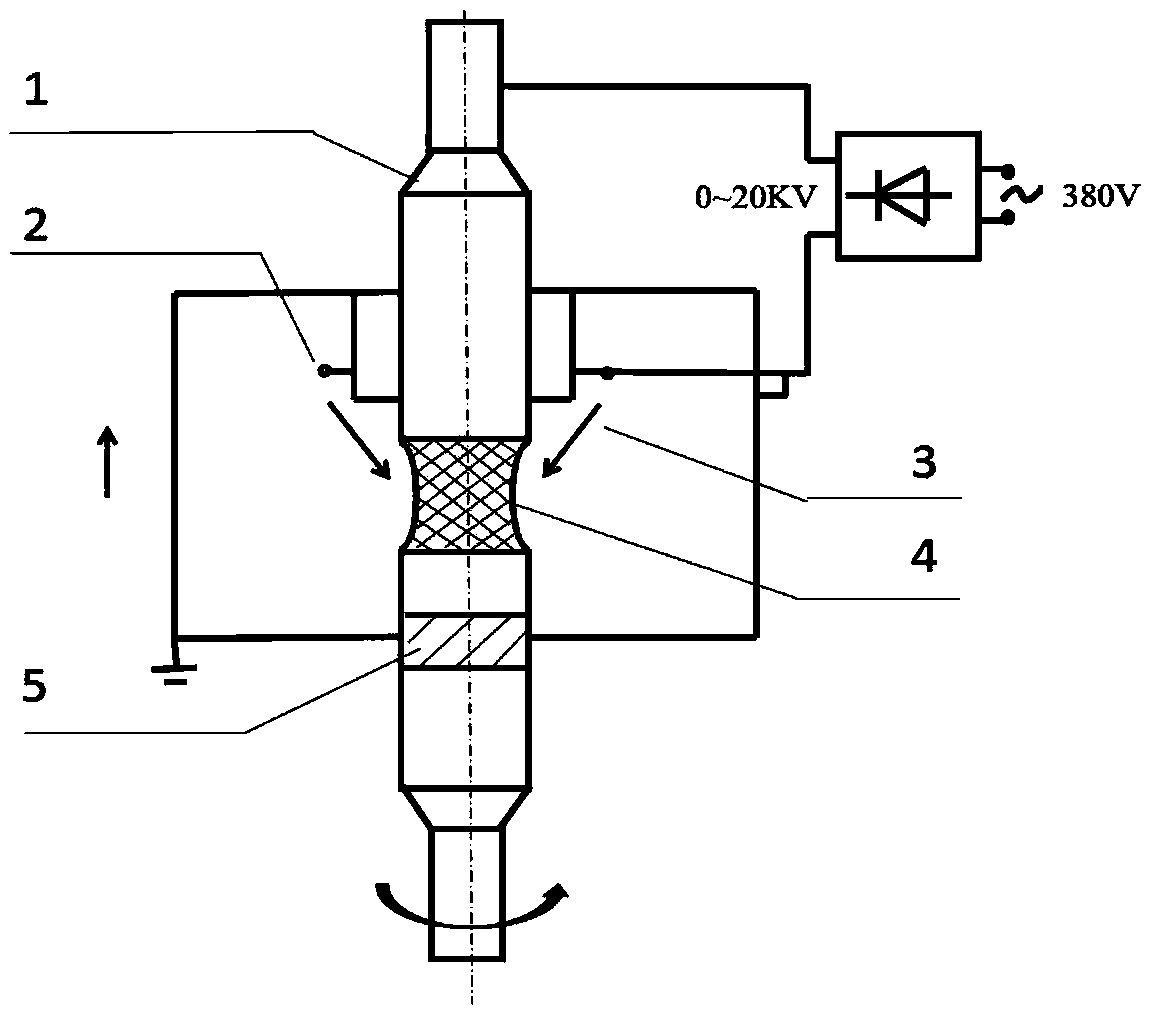

[0041] This embodiment is a method for preparing a rare and precious metal iridium single crystal using a vacuum electron beam zone melting furnace as the equipment and using the electron beam suspension zone melting technology. The specific process is:

[0042] Step 1, calibrate the iridium rod. The iridium rod diameter is Φ6mm, long 300mm, the electron gun is annular, and the iridium rod is placed vertically at the ring center of the electron gun; the initial position of the electron gun is located at 50mm away from the lower end surface of the iridium rod. During zone melting, the direction of electron gun travel is from bottom to top. The straightness of the iridium rod affects the feeding balance in the melting zone, so the straightness of the iridium rod is required to be ≤1mm / m. The iridium rod is repeatedly clamped and corrected in a vise until the conditions are met. After calibration, there will be new impurities on the surface of the iridium rod. Use 1500# sandpa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com