Engine misfire detection method and device

A detection method and engine technology, applied in the direction of internal combustion engine testing, etc., can solve the problems of poor real-time performance, high probability of misjudgment, limited life, etc., and achieve the effects of excellent reliability and real-time performance, simple software and hardware, and flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

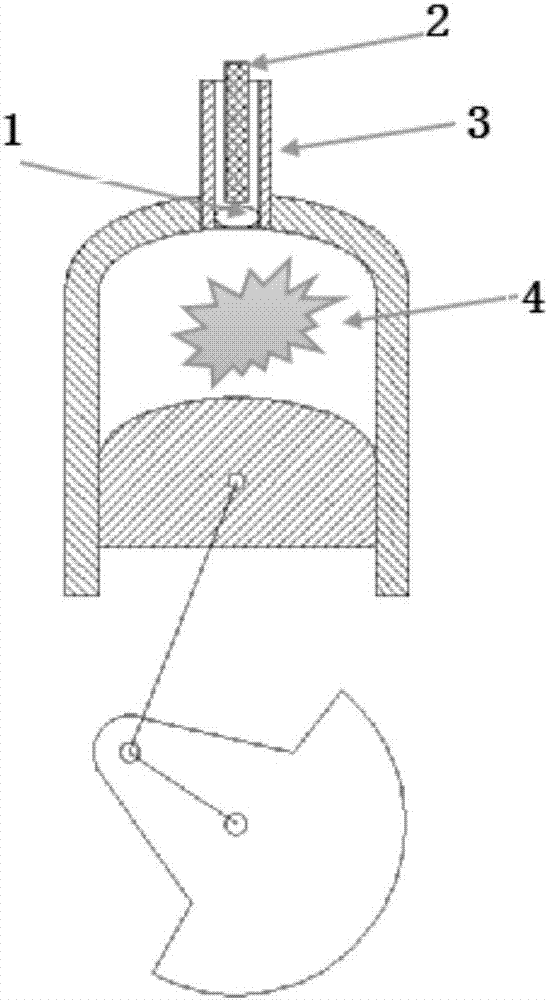

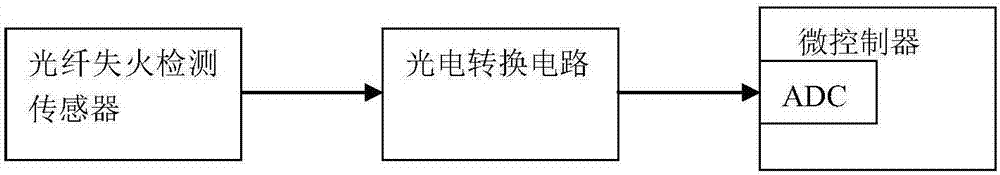

[0026] figure 1 Describe the misfire detection principle of the present invention, when the high-temperature mixture is combusted in the engine cylinder, the high-temperature thermal infrared radiation formed at this time can be detected in the engine cylinder. Through the focusing of the quartz lens, the infrared radiation is transmitted to the external infrared detection photoelectric conversion circuit by light for identification, thereby providing misfire information for engine control.

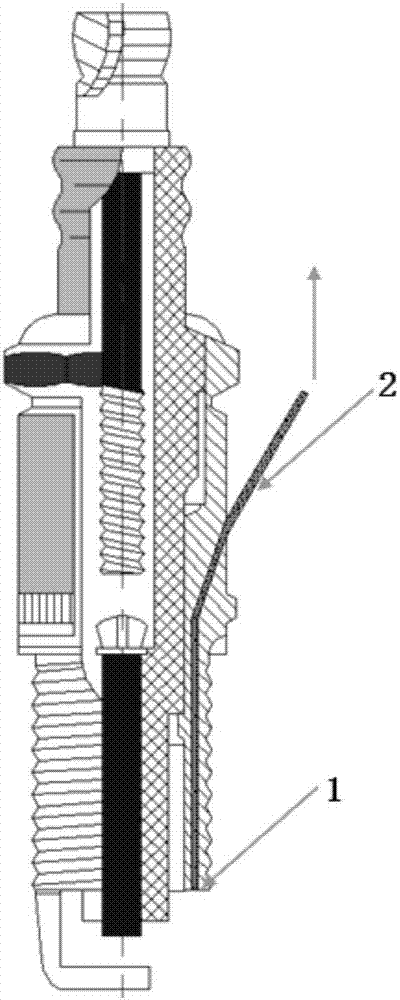

[0027] figure 2 Describe the installation method of the misfire of the present invention on the spark plug of an ignition type engine, by opening a guide hole capable of accommodating an optical fiber on the outer wall of the spark plug. At the bottom of the spark plug, a tiny quartz lens is installed to focus the optical fiber. At the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com