Superconducting graphene composite cable

A graphene composite and graphene layer technology, applied in the field of power transmission system, can solve the problems of weak fault current impulse capability, weak effective resistance, instability, etc., and achieve the effect of superior electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

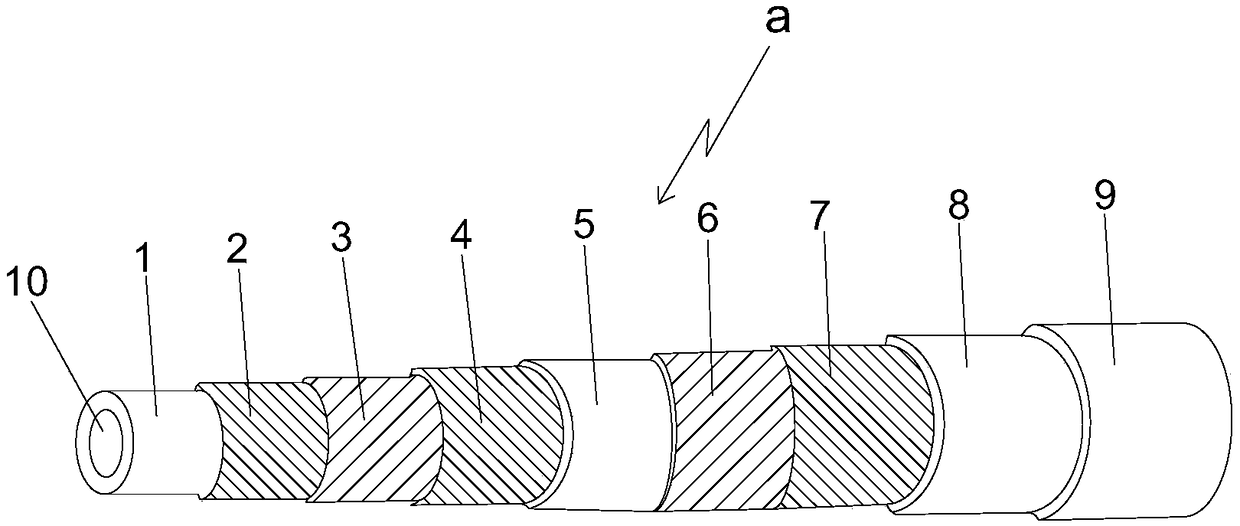

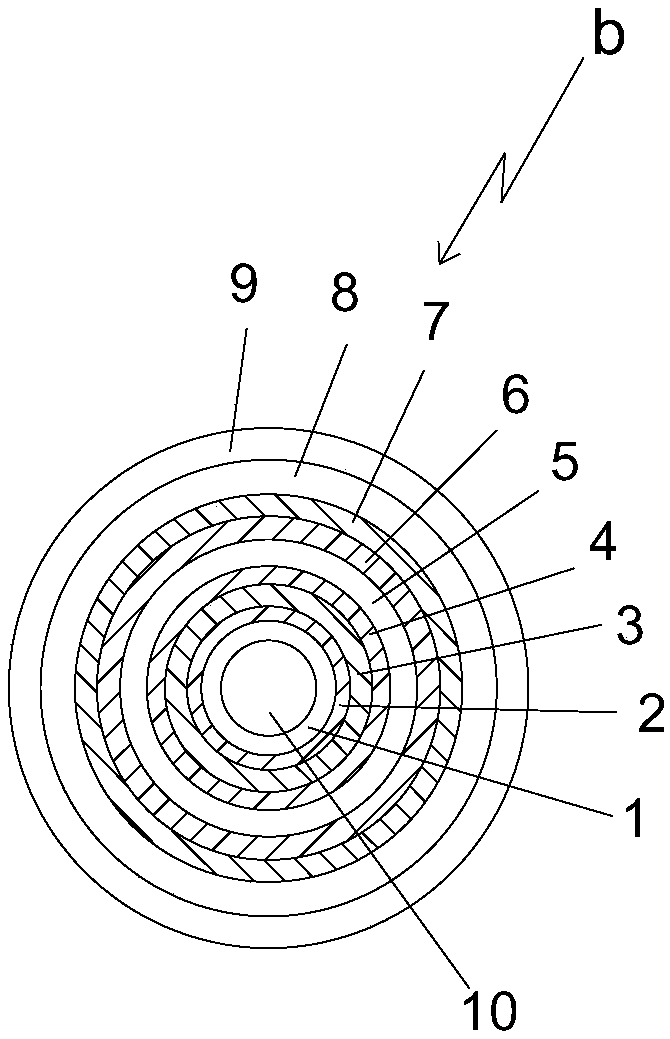

[0032] The structure schematic diagram a of the single-phase cold insulation type high temperature superconducting graphene composite cable of the present invention is as follows figure 1 As shown, the structural cross-sectional schematic b of the single-phase cold-insulated high-temperature superconducting graphene composite cable is shown in figure 2 As shown, its structure from inside to outside is: inner support tube core 1, graphene layer 2, superconductor layer 3, graphene layer 4, electrical insulation layer 5, superconducting shielding layer 6, graphene layer 7, heat insulation layer 8. Protective layer 9; its main structural feature is that the electrical insulating layer 5 is located in the heat insulating layer 8, and works under a liquid nitrogen temperature environment; its main structural feature is that: a graphene layer 2, a superconductor layer 3, and a graphene layer 4 form a sandwich Sandwich configuration, one side of the graphene layer 2 is connected to t...

Embodiment 2

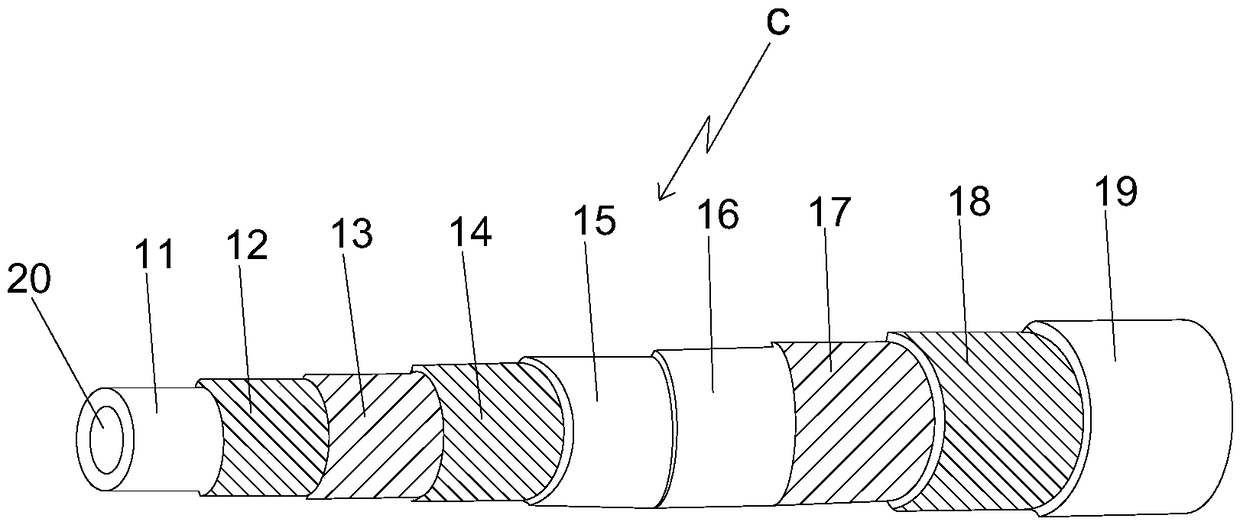

[0037] Structural schematic diagram c of single-phase thermal insulation type high temperature superconducting graphene composite cable of the present invention is as image 3 As shown, the structural cross-sectional schematic diagram of the single-phase cold-insulated high-temperature superconducting graphene composite cable d is shown in Figure 4 As shown, the electrical insulation layer 16 is placed outside the heat insulation layer 15 and is at ambient temperature. 15. Electrical insulating layer 16, superconducting shielding layer 17, graphene layer 18, and protective layer 19; its main structural features are: graphene layer 12, superconductor layer 13, and graphene layer 14 form a sandwich configuration, and graphene One side of the layer 12 is connected to the outer side of the inner support tube core 11 that circulates liquid nitrogen 20, and the other side of the graphene layer 12 is connected to the superconductor layer 13, and they together form a graphene composi...

Embodiment 3

[0042] The structural representation e of the three-phase parallel axis cold insulation type high temperature superconducting graphene composite cable of the present invention is as Figure 5 As shown, the schematic cross-section of the structure of the three-phase parallel-axis cold-insulated high-temperature superconducting graphene composite cable f is as Figure 6As shown, the three-phase independent electrical insulation layers 25 of each phase are placed in a unified heat insulation layer 28, and the ABC three-phase cables are all in a liquid nitrogen low-temperature environment during operation; the structures of each phase of the ABC three-phase cables are basically the same, from the inside to the The outer parts are: inner support tube core 21, graphene layer 22, superconductor layer 23, graphene layer 24, electrical insulating layer 25, superconducting shielding layer 26, graphene layer 27, heat insulating layer 28, protective layer 29; its ABC The main structural f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com