Safe and anti-explosion cover plate for power lithium battery

A technology of lithium battery and explosion-proof cover, which is applied in the direction of battery cover/end cover, secondary battery, battery pack components, etc., which can solve the problems of increasing the risk of battery thermal runaway, rising battery temperature, and oxidation of negative pole pieces. Avoid the risk of spontaneous combustion, prevent air oxidation, and have good sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

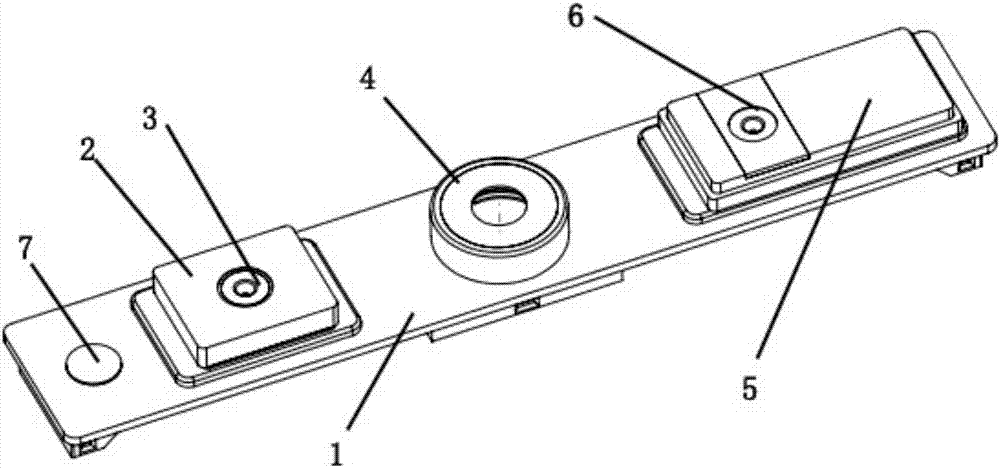

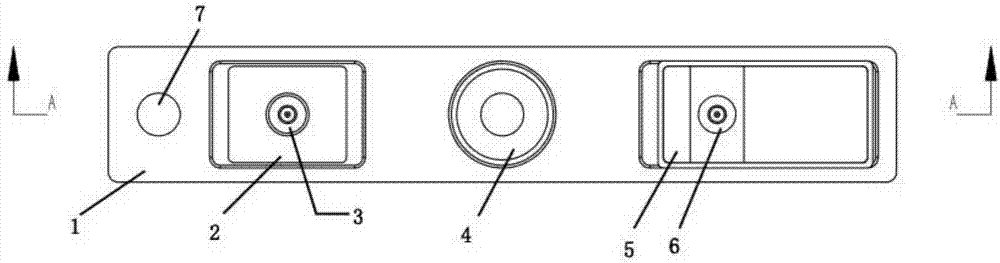

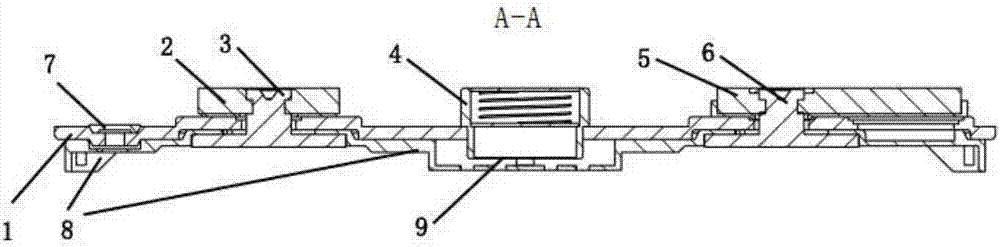

[0021] Such as Figure 1-Figure 3 A power lithium battery safety explosion-proof cover plate is shown, including a cover plate substrate 1 with an explosion-proof hole, an explosion-proof valve 4 installed in the explosion-proof hole, and a positive pole column 2 and a negative electrode installed on the cover plate substrate 1 in sequence. Pole 5. The explosion-proof valve 4 is welded on the explosion-proof hole on the cover substrate 1 by laser welding.

[0022] Further, a liquid injection port is opened on the cover substrate 1 , and a liquid injection port sealing piece 7 made of aluminum alloy stamping is arranged above the liquid injection port. The liquid injection port sealing piece 7 is welded on the cover substrate 1 by laser welding.

[0023] Further, the positive pole 2 and the negative pole 5 are installed on the cover substrate 1 through the rivet 3 for fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com