A cyclic purification control method for uranium content in an ultra-precision machine tool processing area

An ultra-precision machine tool and processing area technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as endangering the physical and mental health and safety of workers, unable to purify uranium dust or uranium aerosol, etc. Physical and mental health, the effect of avoiding the risk of spontaneous combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

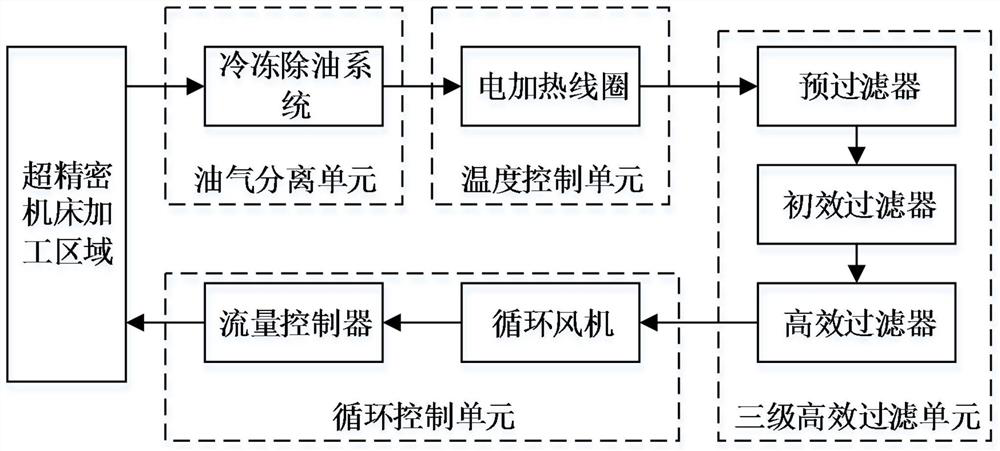

[0026] like figure 1 As shown, a method for cyclic purification of uranium content in an ultra-precision machine tool processing area includes an oil and gas separation unit connected to the ultra-precision machine tool processing area through a trachea, and the oil and gas separation unit is sequentially connected with a temperature control unit, a three-stage high-efficiency filter unit and a trachea through the trachea. Circulation control unit, the circulation control unit is connected with the processing area of the ultra-precision machine tool through the air pipe;

[0027] The oil and gas separation unit is used to filter the impurities of the machine tool hydraulic oil in the gas in the ultra-precision machine tool processing area;

[0028] The temperature control unit is used to realize the temperature control of the flowing gas;

[0029] The three-stage high-efficiency filter unit is used to filter the uranium-containing impurities in the gas;

[0030] The circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com