Two-phase heat exchanger and system utilizing cement kiln waste heat to dry sludge

A drying sludge and cement kiln technology, which is applied in dehydration/drying/thickened sludge treatment, indirect heat exchanger, waste heat treatment, etc., can solve the problems of easy bonding of the wall, reduced use value, and unstable state of wet sludge. Stability and other issues, to achieve the effect of high comprehensive thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

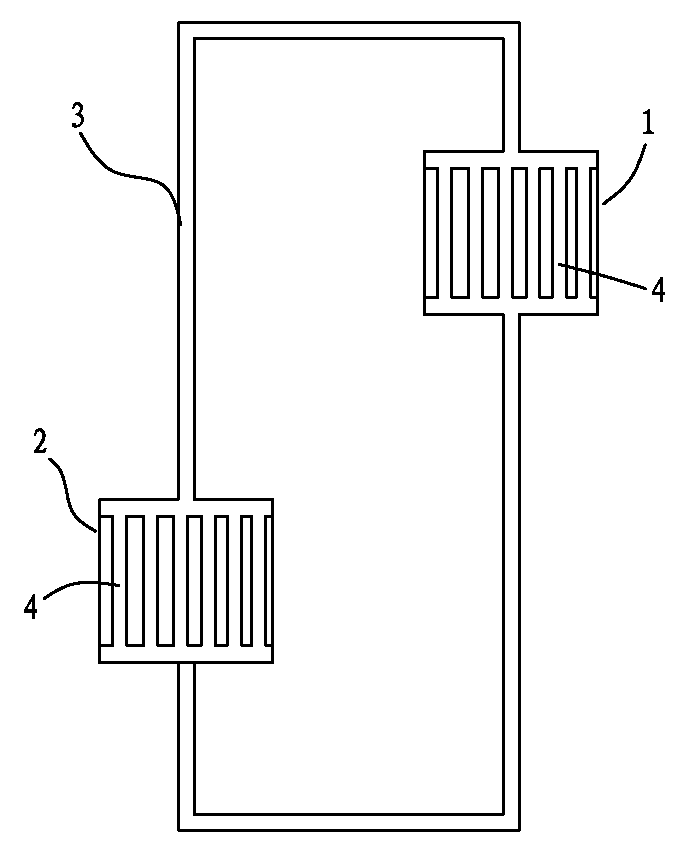

[0021] An embodiment of a closed two-phase heat exchanger, see figure 1 , the heat exchanger includes two evaporating sections 2 and condensing sections 1, one high and the other low, which are not arranged on a horizontal plane, the bottom of the condensing section is higher than the top of the evaporating section, and the evaporating section 2 and the condensing section are connected in series through a pipeline 3 connected to form a closed loop space, air is drawn from the loop space to form a vacuum loop, pure water or distilled water is placed in the loop, and the pure water fills the evaporating section, and the evaporating section 2 and the condensing section are respectively composed of multiple It is composed of 4 vertically arranged metal tubes, and the metal tubes are connected in parallel with each other. The above-mentioned heat exchanger structure is a closed two-phase fluid heat transfer technology, that is, a device that transfers heat by relying on the phase c...

Embodiment 2

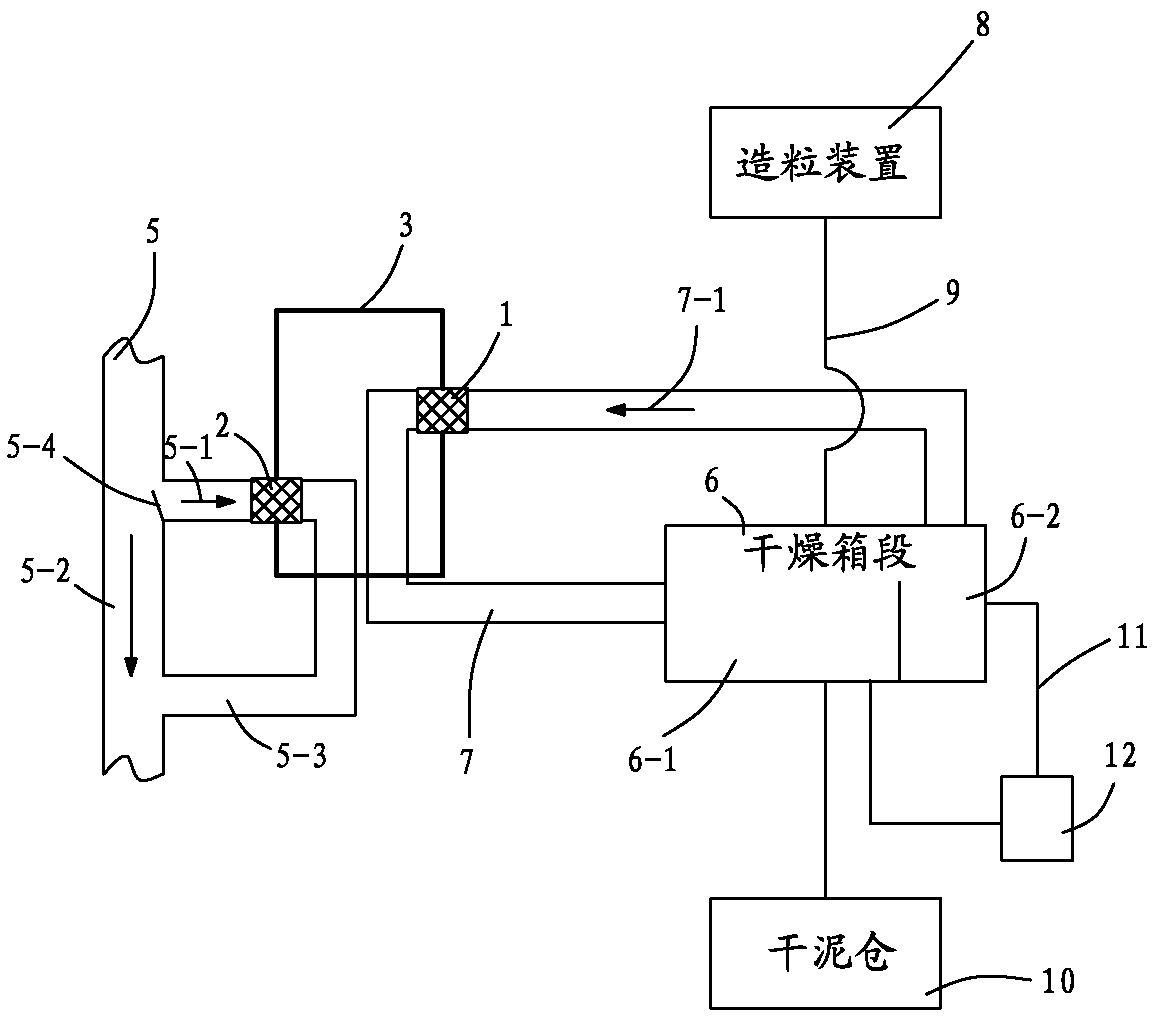

[0025] An embodiment of a system for drying sludge with waste heat from a cement kiln, see figure 2 And embodiment 1, described system comprises garbage disposal cement kiln flue gas pipeline 5 and sludge drier, and described sludge drier has a drying box section 6 that passes through sludge, and a hot air conveying pipeline 7 is connected with drying box section wherein, the closed two-phase heat exchanger as described in Embodiment 1 is arranged between the exhaust pipe and the hot air conveying pipe; The evaporating section 2 and the condensing section 1, the bottom of the condensing section is higher than the top of the evaporating section, the evaporating section and the condensing section are connected in series through pipelines to form a closed loop space, and air is drawn from the loop space to form a vacuum loop, Pure water is placed in the vacuum loop, and the water level of the pure water fills the evaporation section and is lower than the bottom of the condensati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com