Molecular ratio control system for alkylate raw material

A raw material molecule and control system technology, applied in the direction of feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve problems affecting the reaction effect, increasing the load of the alkylation device, affecting the production capacity of the device, etc., to achieve guaranteed Product quality, the effect of avoiding production fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

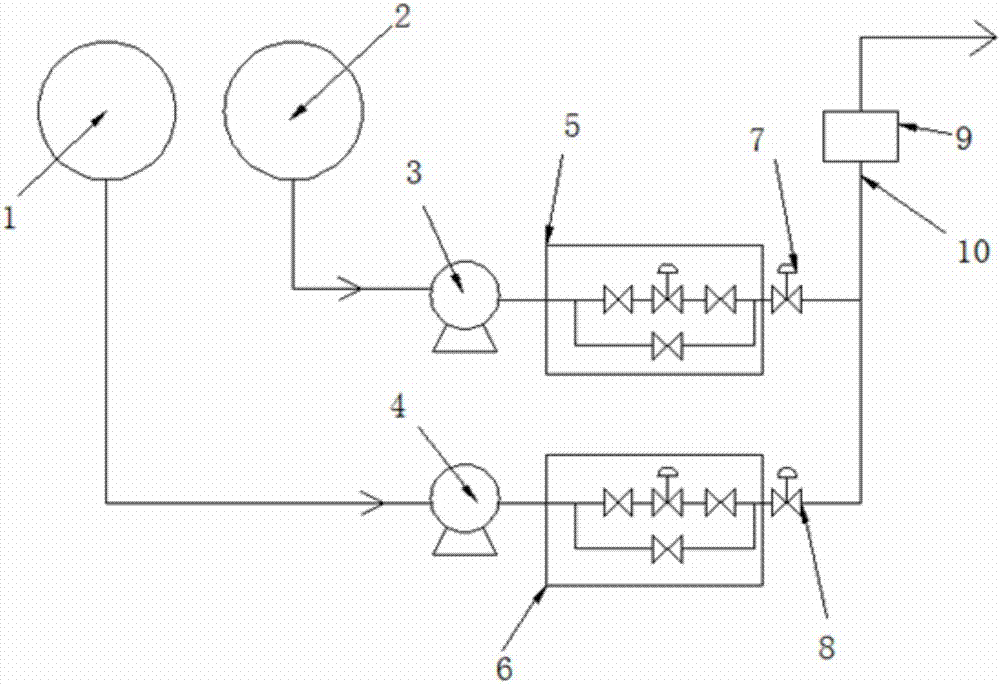

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] see as figure 1 As shown, the technical scheme adopted in this specific embodiment is: it comprises high olefin raw material tank 1, isobutane raw material tank 2, No. 1 pump 3, No. 2 pump 4, No. 1 valve group 5, No. 2 valve group 6, No. 1 flow meter 7 and No. 2 flow meter 8; high olefin raw material tank 1 is connected to No. 2 pump 4 through pipelines, No. 2 pump 4 is connected to No. 2 valve group 6 through pipelines, No. The flowmeter 8 is connected; the isobutane raw material tank 2 is connected with the No. 1 pump 3 through the pipeline, and the No. 1 pump 3 is connected with the No. 1 valve group 5 through the pipeline, and the No. 1 valve group 5 is connected with the No. 1 flowmeter 7 through the pipeline. Connection; the outlets of the No. 1 flow meter 7 and the No. 2 flow meter 8 are connected to the raw material feeding device after being connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com