Production system with heat conduction oil as heat source

A technology of production system and heat transfer oil, applied in the field of production system, can solve the problems of steam condensed water entering the wastewater system, increasing the load of wastewater treatment, affecting production efficiency, etc., and achieving the effects of facilitating production regulation, reducing wastewater, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

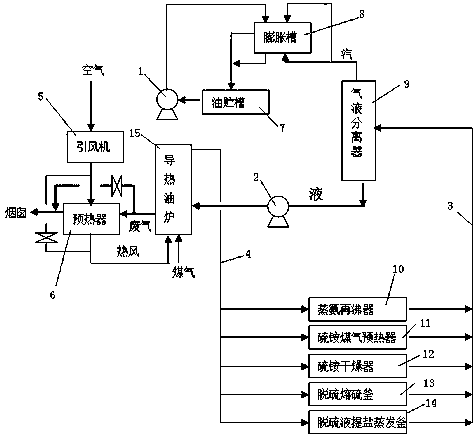

[0025] see figure 1 , a production system using heat conduction oil as a heat source, including an induced draft fan 5, a preheater 6, an oil storage tank 7, an expansion tank 8, a gas-liquid separator 9, an ammonia distillation reboiler 10, and an ammonium sulfate gas preheater 11. Ammonium sulfate dryer 12, ammonium sulfate melting sulfur kettle 13, desulfurization liquid salt extracting evaporation kettle 14 and heat conduction oil furnace 15; the waste gas outlet end of the heat conduction oil furnace 15 is connected to the preheater 6, and the induced draft fan 5 is connected to Preheater 6, the preheater 6 is connected with a chimney, the hot air outlet end of the preheater 6 is connected to the heat transfer oil furnace 15, and the heat transfer oil furnace 15 is respectively connected to the ammonia steaming reboiler 10, Ammonium sulfate g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com