Air cooled spindle exhaust air redirection system for enhanced machining byproduct recovery

A technology for recycling systems and by-products, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as reducing machine effectiveness, environmental problems, drilling system mechanical problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

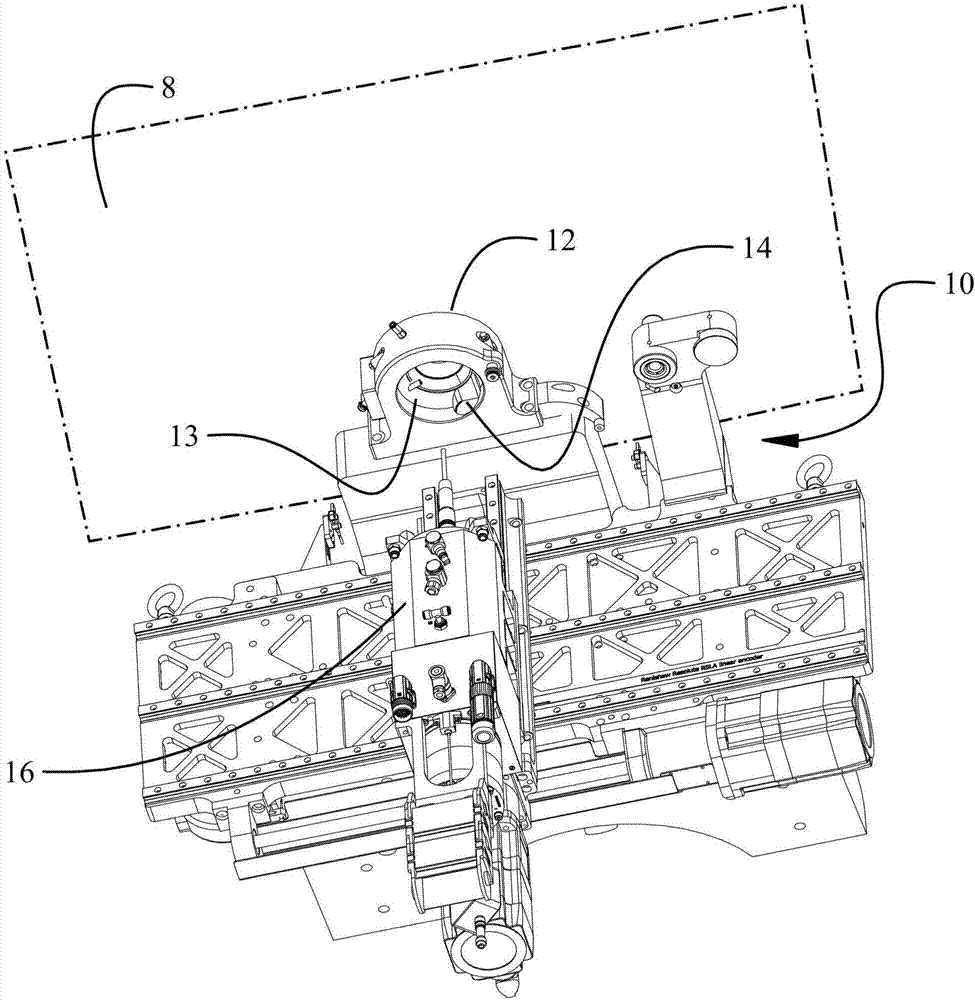

[0031] Clause 1. A processing by-product recovery system, the processing by-product recovery system comprising:

[0032] a vacuum shield positioned adjacent to the workpiece;

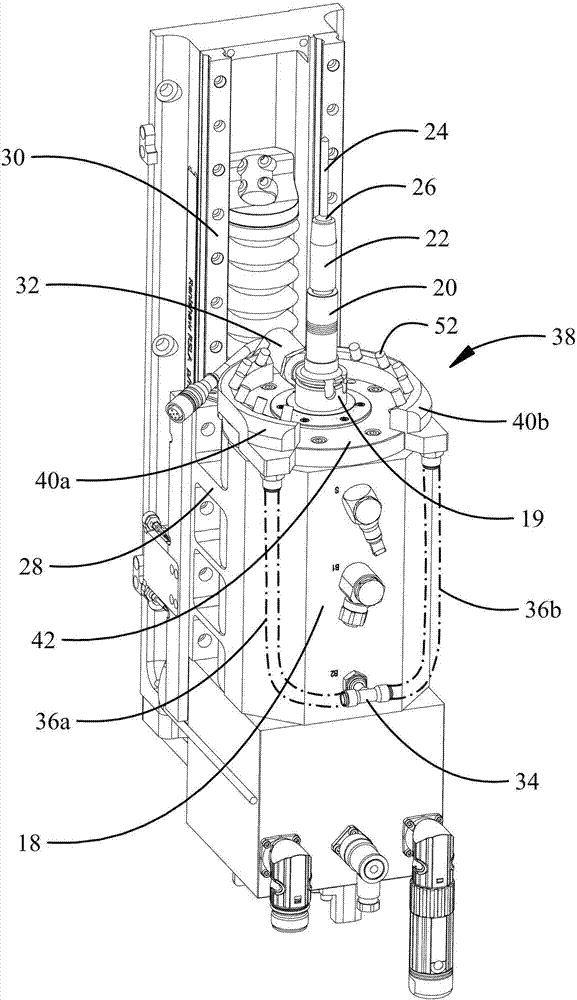

[0033] a spindle extending from the base and engaging a tool, the spindle reciprocating the tool vertically up through an aperture in the vacuum shield to engage the workpiece; and

[0034] A circumferential air jet is emitted proximate to the base of the spindle and directed towards the vacuum shroud.

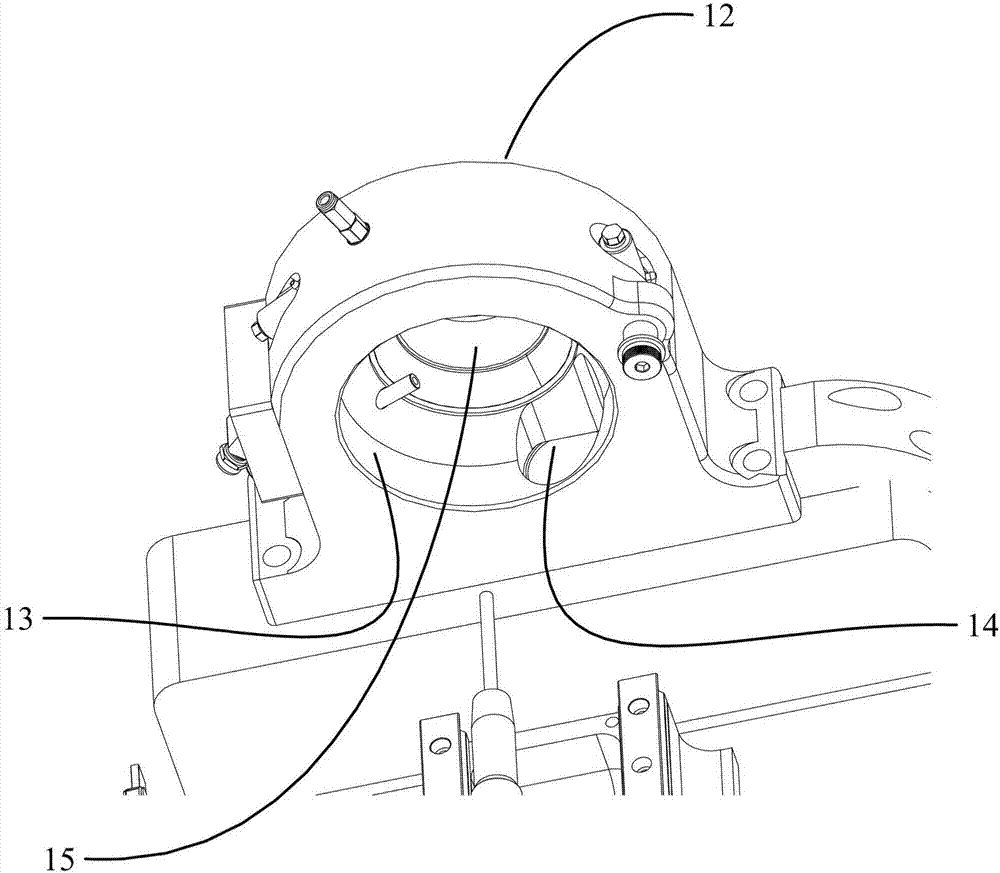

[0035] Clause 2. The process by-product recovery system of clause 1, wherein the vacuum shroud is mounted in a presser foot adapted to engage the workpiece.

[0036] Clause 3. The process by-product recovery system of clause 1 or 2, wherein the spindle and base are operably mounted in a motor drive system having a top flange, and the circumferential air jet flows from Manifold launch mounted to the top flange.

[0037] Clause 4. The process by-product recovery system of Clause 3, wherein said motor d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com