Device for polishing surface of spherical joint of high-pressure oil pipe

A ball joint, surface polishing technology, applied in surface polishing machine tools, grinding drives, grinding/polishing equipment, etc., can solve problems such as being unable to adapt to mass production, difficult to ensure consistent results, and affecting the normal use of products, etc. Achieve the effect of avoiding poor consistency of polishing effect, avoiding unstable polishing quality and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

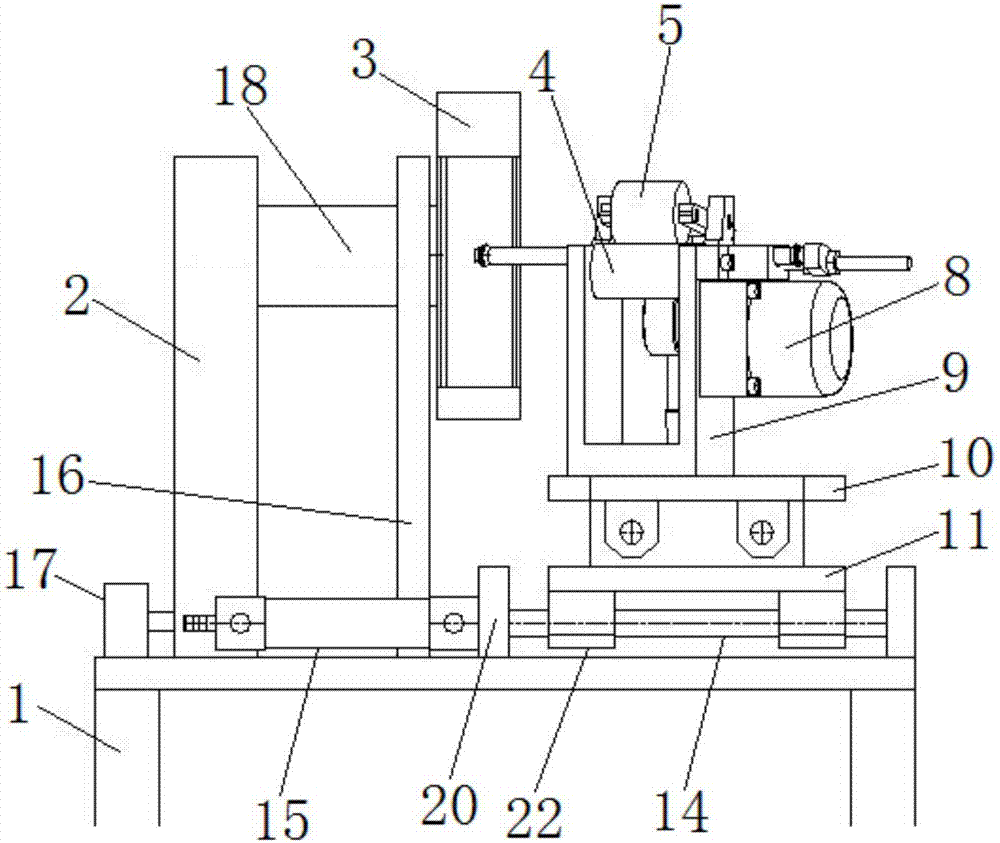

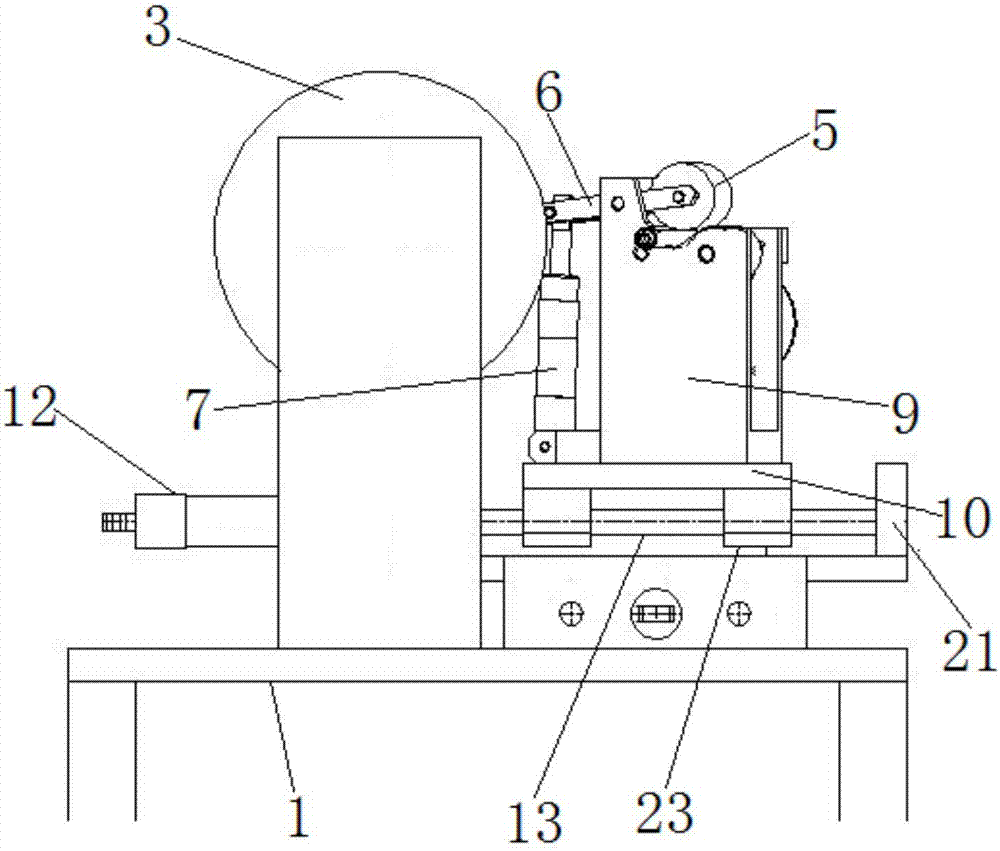

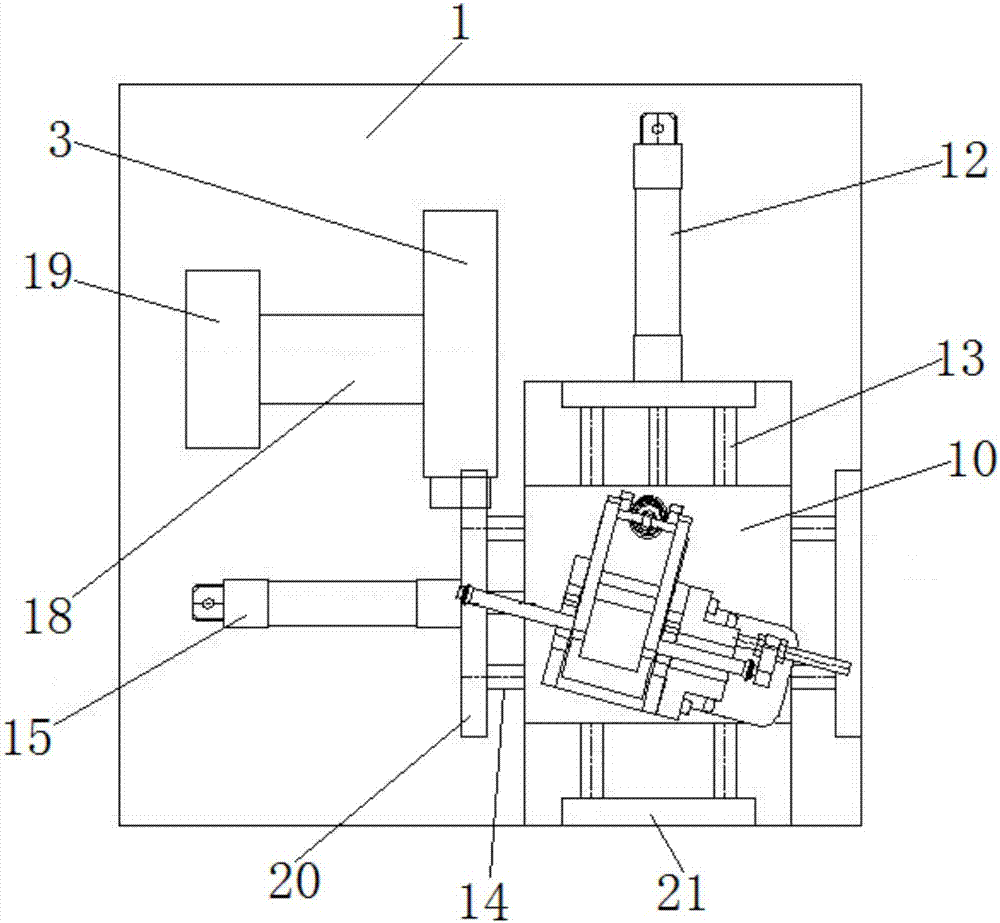

[0028] Such as Figure 1 to Figure 3 Shown is a device for polishing the surface of a ball joint of a high-pressure oil pipe. The device includes a workbench 1, a polishing mechanism and a part moving mechanism arranged on the workbench 1, a part supporting mechanism arranged on the part moving mechanism, and a part supporting mechanism arranged on the workbench 1. The part pressing mechanism on the part moving mechanism and matched with the part supporting mechanism, places the high-pressure oil pipe with a ball joint at one end between the part supporting mechanism and the part pressing mechanism, and moves to the preset position through the part moving mechanism , the surface of the ball joint is polished by the polishing mechanism.

[0029] Wherein, the polishing mechanism includes a polishing wheel support 16 disposed on the workbench 1 , a polishing wheel 3 disposed on the polishing wheel support 16 , and a polishing wheel drive motor 17 connected to the polishing wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com