Grooving equipment for oriented strand board

A technology of oriented structural board and slotting equipment, which is applied in slotting machines, mortising machines, wood processing appliances, etc., can solve the problems of large physical injury and low efficiency of workers, and achieve less leftovers and increase production. Efficient and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

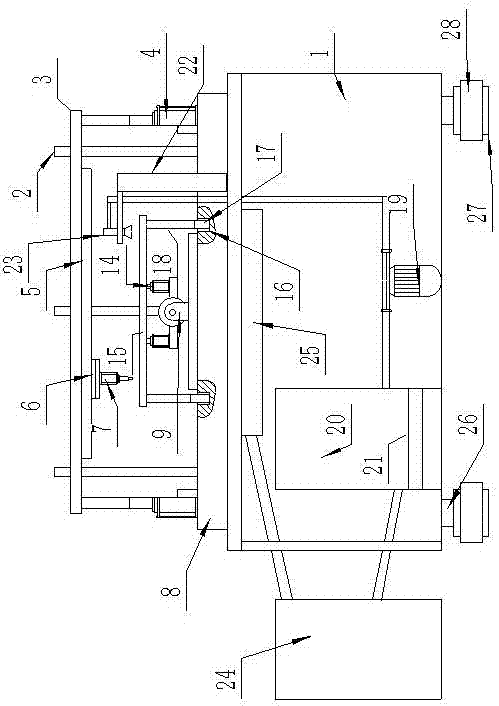

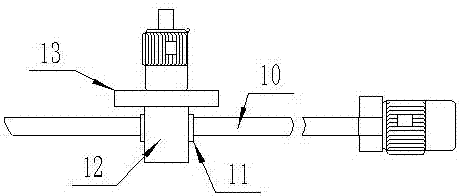

[0019] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, a slotting device for an oriented structure plate includes a workbench 1, the inside of which is a hollow structure; Fix the lifting and clamping mechanism, the slotting mechanism is composed of three guide columns 2 installed on the workbench 1, a lifting plate 3 set on the three guide columns 2, and installed on the workbench 1; and electric push rods near its two ends 4. Installed on the lower end surface of the lifting plate 3; and the rodless cylinder 5 extending along its length direction, the stabilizer 6 fixed on the moving end of the rodless cylinder 5, the driving member 7 fixedly connected to the stabilizer 6 and the driver mounted on the drive The slotting knife at the driving end of the part 7 is jointly formed; the lifting and clamping mechanism is composed of a fixed plate 8 on the workbench 1, a pair of shaft brackets 9 arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com