Ceramic modification C/C composite material with ceramic coating layer and preparation method thereof

A composite material and ceramic coating technology, which is applied in the field of C/C composite material and its preparation, achieves the effects of simple equipment process, controllable coating structure content, and improved linear expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

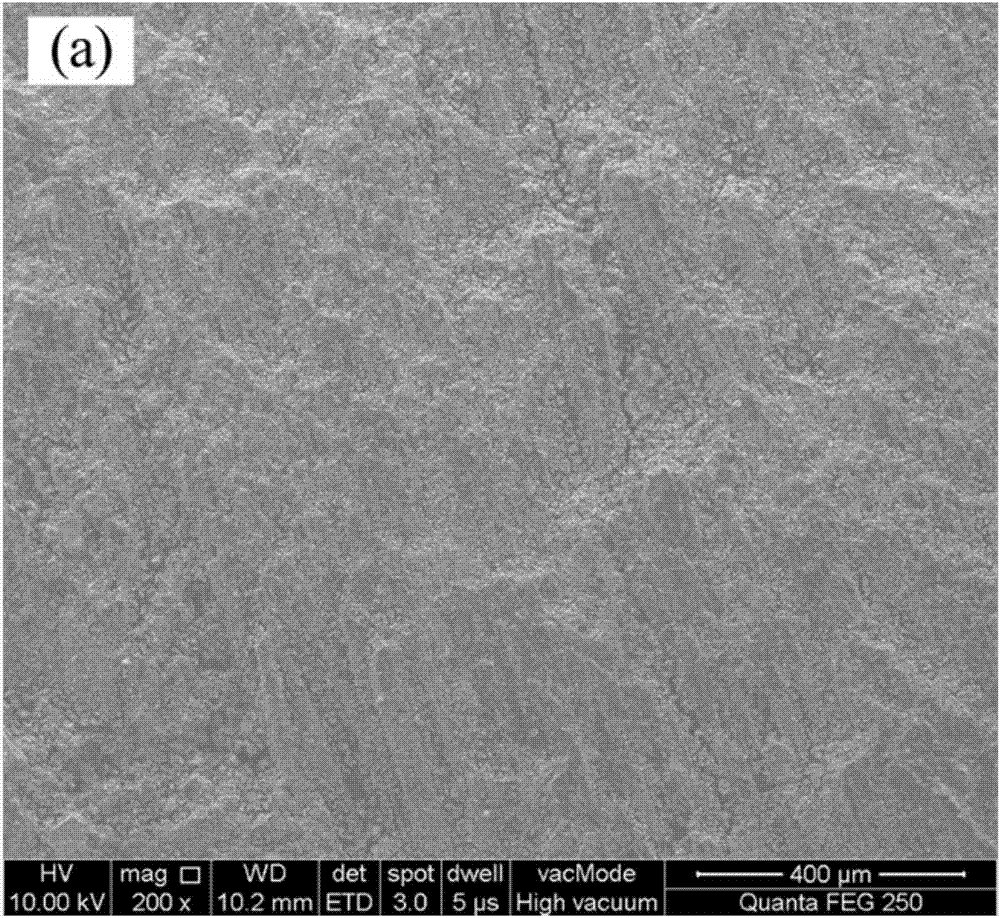

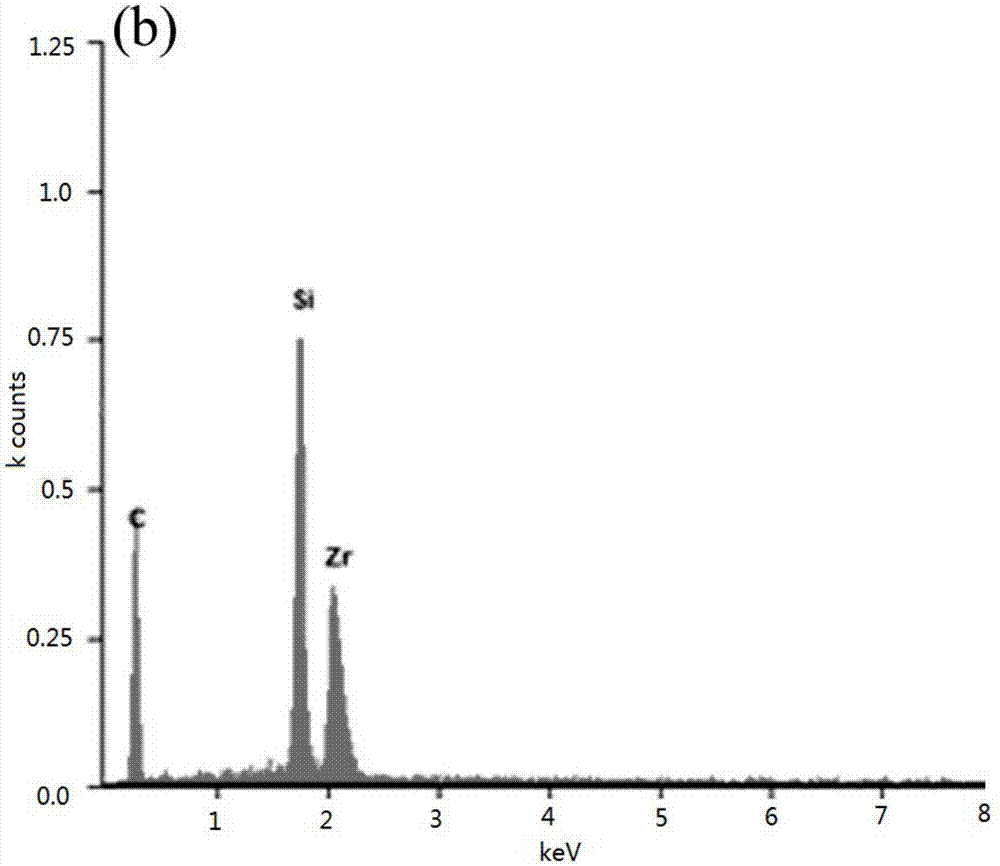

[0043] Example 1: Using three-dimensional punctured carbon felt as a carbon fiber preform, the density of the carbon fiber preform is 0.8g / cm 3 . First, the carbon fiber preform is densified by a chemical vapor deposition process. The densification process uses propylene as the carbon source gas, nitrogen as the carrier gas, the deposition temperature is 980°C, and the deposition pressure is less than 3kPa. Made by chemical vapor deposition with a density of 1.3g / cm 3 C / C composite materials. Using polycarbosilane and zirconium alkoxide as the precursor of organic ceramics, the two were mixed and dissolved in xylene at a mass ratio of 1:1 to form an organic ceramic precursor solution, and the C / C porous The body undergoes repeated ultra-high temperature ceramic densification treatments. The specific process is as follows: put the C / C composite material prepared by chemical vapor deposition into the impregnation tank, evacuate to below 2kPa, put in the organic ceramic precu...

Embodiment 2

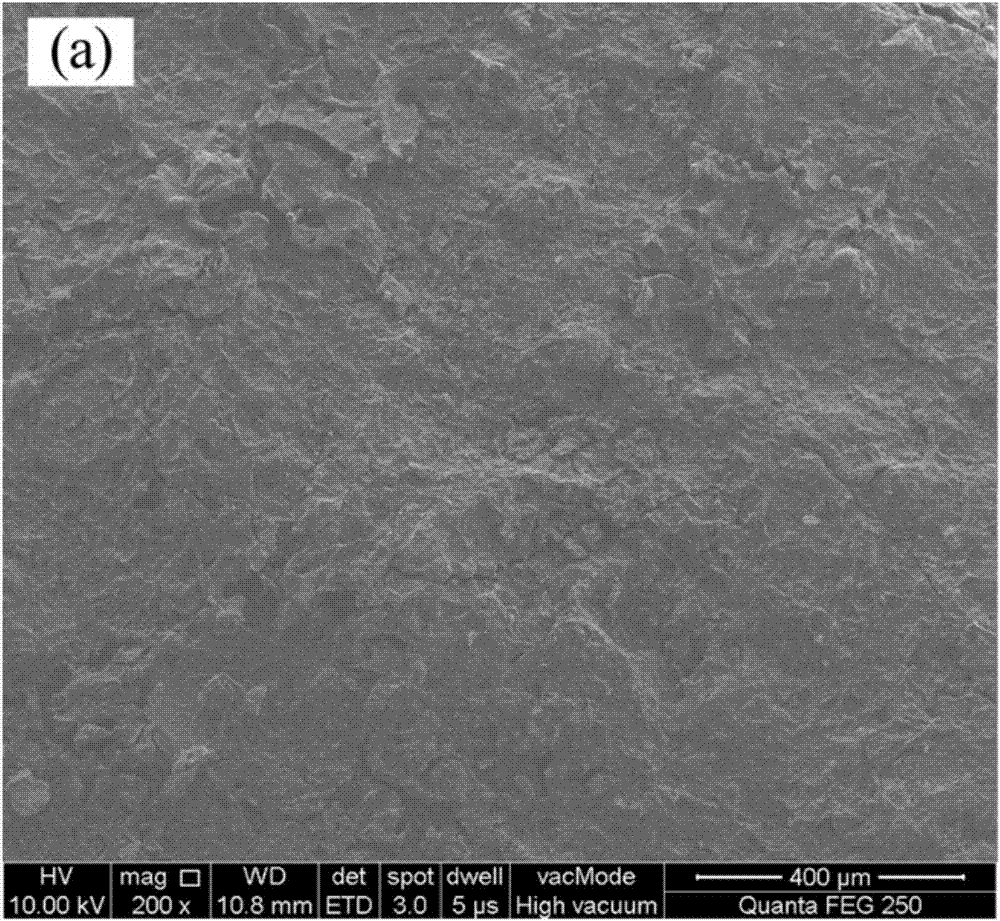

[0047] Example 2: Using needle-punched carbon felt as a carbon fiber preform, the carbon fiber preform is first densified by a chemical vapor deposition process. The densification process uses propylene as the carbon source gas, nitrogen as the carrier gas, the deposition temperature is 980°C, and the deposition pressure is less than 3kPa. After chemical vapor deposition, the prepared density is 1.52g / cm 3 C / C composite materials. Using polycarbosilane and zirconium alkoxide as the precursor of organic ceramics, the two were mixed and dissolved in xylene at a mass ratio of 1:1 to form an organic ceramic precursor solution, and the C / C porous The body undergoes repeated ultra-high temperature ceramic densification treatments. The specific process is as follows: put the C / C composite material prepared by chemical vapor deposition into the impregnation tank, evacuate to below 1kPa, put in the organic ceramic precursor solution to immerse the C / C porous body, and take out the bl...

Embodiment 3

[0051] Embodiment 3: Select needle-punched laminated carbon felt as carbon fiber preform, and the density of carbon fiber preform is 0.56g / cm 3 . First, the carbon fiber preform is densified by a chemical vapor deposition process. The densification process uses propylene as the carbon source gas, nitrogen as the carrier gas, the deposition temperature is 980°C, and the deposition pressure is less than 3kPa. After chemical vapor deposition, the prepared density is 1.3g / cm 3 C / C composite materials. Using zirconium alkoxide and hafnium alkoxide as the precursor of organic ceramics, the C / C porous body is subjected to repeated ultra-high temperature ceramic densification treatment by the ceramic precursor impregnation-cracking process. The specific process is as follows: put the C / C composite material prepared by chemical vapor deposition into the impregnation tank, evacuate to below 1kPa, put in the organic ceramic precursor solution to immerse the C / C porous body, and take o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com